Using Arduino and 3D Printer Joan Paul Laksis built a device to automatically feed, water or snap for his dog. This is a 3D printed product have an impressive looking, functional machine which can be built by any individual with a 3D printer and an intermediate level of electronics, programming and DIY experience.

Maker Joan Paul Laksis describes his inspiration for the 3D printed feeder as coming from his dog. Dentastix (Laksis dog), need to feed at the same time of the day every day. Being a machine designer by trade maker Joan Paul has decided to combat this problem by designing a 3D-printed Arduino powered dog feeder to automate this task so he can become more self reliant.

It functions as, dog places its paw on a lever which activates the machine. This cycle happens every 8 hours, if the cycle has not yet elapsed and the dog tries to place it paw it was not going to work. When the machine is not in operation, it will be in idle state to conserve battery, refilling of the machine is made manually.

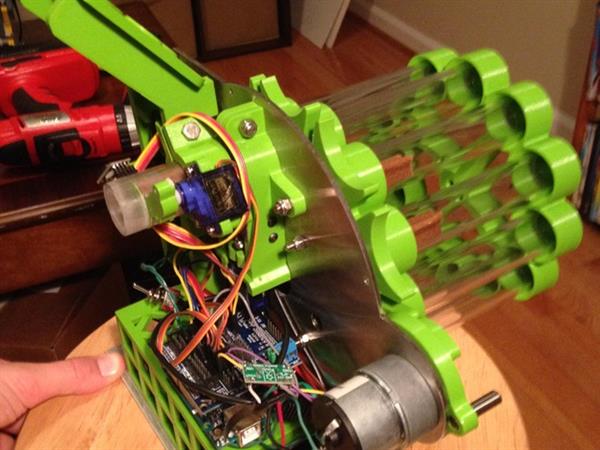

The 3D printed feeder is capable to track number of times and the number of treats remaining in the present load tube. These values are stored in EEPROM of an embedded Arduino Uno (Atmega328). The feeder is designed in Solidworks and 3D printed each of its plastic components in lime green PLA with an AVR- powered Ultimaker 2. In addition to this, the machine also consists of 12 non 3D printed 6inch clear acrylic tubes and a laser cut sheet metal base.

This DIY device is handy for, pet owners simply aren’t able to provide essential treats for their animal friends at the right time of the day, every day.

Filed Under: Reviews

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.