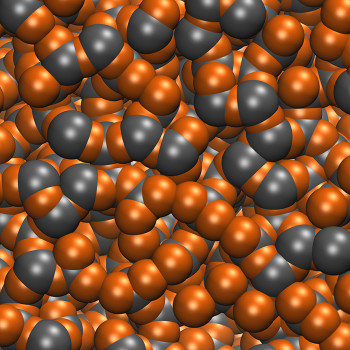

A lot of manufacturers choose plastic out of choice because of its simple ability to get molded in any size and shape and simple availability at a pocket friendly price. But these fall behind several counterparts in terms of strength and sustainability. These also lack electrical conduction properties and mostly act as insulators. A better option under such conditions is offered by metallic glasses or amorphous metal-alloys. These stand behind the metallic solids for lacking a crystalline structure. Similar to the normal glasses, these get soft and start flowing in presence of heat. This property makes these absolutely suitable for molding purposes.

However till date identification and creation of these glasses was a tough and costly task. The alloys are formed by combining three or more metals. One can identify an amorphous alloy only by mixing it, cooling it, and then physically identifying it if its structure is crystalline or not. Apart from this, most experiments included in metallic glasses need some very expensive elements like palladium or gold.

But a team of researchers from Harvard, Yale, and Duke has found a way to predict the metals combination that will lead to formation of amorphous alloys even before synthesis. Thanks to the step by step testing of several combinations of metals’ and their crystalline properties. Most alloys result in formation of a crystalline structure after cooling. The others, however, carry diverse crystal patterns that be formed potentially. In the amorphous metals, the most potential patterns have identical formation energies that compete with each other to carry out the final formation within the alloy.

The research team worked on identifying the “optimum” size of crystalline area that must be obtained for producing crystalline growth in complete metal. They found that the simultaneous formation of multiple crystalline nuclei can always prevent any single nucleus from attaining its optimum or critical size. This keeps the formation of crystalline structure on a whole and compels the alloy to stay amorphous in its solid state. They collected data through various experiments to give a solid base to their theory and found that 73 percent of their experiments supported their theory. This ultimately helped them in identifying hundreds of candidates that can be used in formation of metallic glasses.

Filed Under: News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.