The final result of second law of thermodynamics explains that all thermodynamic processes can result in waste heat production. However, if we can learn to trap that waste heat, it can always be used for several other purposes. A team of researchers working at the Ulsan National Institute of Science and Technology (UNIST) recently developed a new technique with the help of paintable materials for recycling waste heat from industrial procedures and turn it into power. The team was successful in creation of high-performance thermoelectric (TE) material that has some liquid properties and it can be painted directly over surface of any heat absorbing surface. It can also be used for enhancing energy efficiency of industrial applications and also capable of filling holes for the requirement of a new renewable source of electric power.

The process highly depends over thermoelectric effect that is potent enough to convert the temperature difference into voltage and vice versa. The thermoelectric effect is also used in small sized cooling systems like the waste heat recovery systems or the automotive cooling systems. A typical thermoelectric module, in use at present, has a rectangular shaped parallelepipeds. The power output of these generators mainly depends over their material properties along with the generators configuration coordinating with the heat source. As in a large number of heat sources give out irregular outputs and lessen the output due to curved surface, a considerable amount of heat is lost as the planar devices fail to coordinate well with curved surfaces.

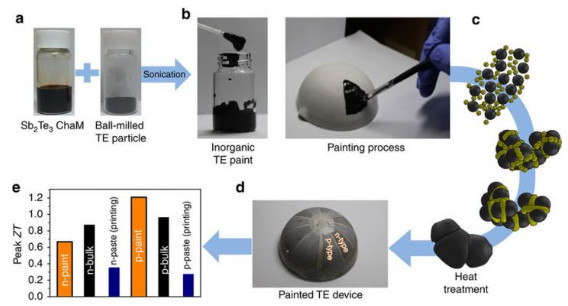

The main aim was to get over these flaws and the team finally developed a shape-engineerable thermoelectric painting technique, here the TE material is brushed over surface directly. The material is made up of Bl2Te3 based inorganic paints that use the Sb2Te3 chalcogenidometalate in form of a sintering aid. The team made examined these TE paints over number of surfaces and showcased that it is a highly efficient way of heat collection that has very high power generation densities of around 4mW/cm2. T.

Filed Under: News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.