People have grown up with the sights and sounds of fluorescent lamps buzzing to life after a few attempts. As the new wave of energy saving appliances gripped the world, technology made the fluorescent lamps shrink in thickness as well as reduced the number of attempts made by lamps to shine their brightest. Today many homes use energy Saver CFL lamps and fluorescent tubes which start giving light the moment they are switched on.

Fig. 1: A Representational Image of an Electronic Ballast Lamp

This instantaneous production of light is achieved by the use of electronic ballasts.

Fig. 2: A Table Representing Various Types of Electronic Ballasts

History

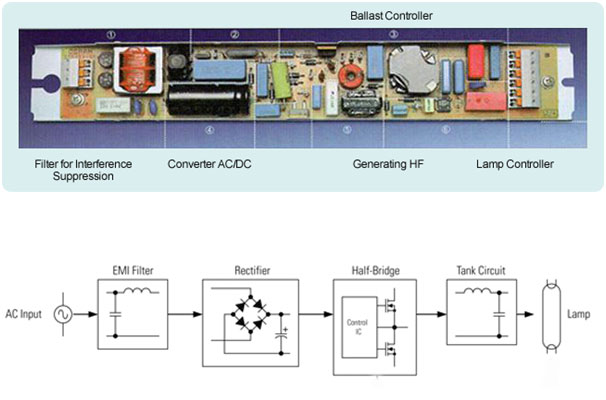

Fig. 3: An Image Representing Architecture and Process Flow of a Ballast Controller

Working

Fig. 4: A Figure Showcasing a Sample Circuit Construction of an Electronic Ballast

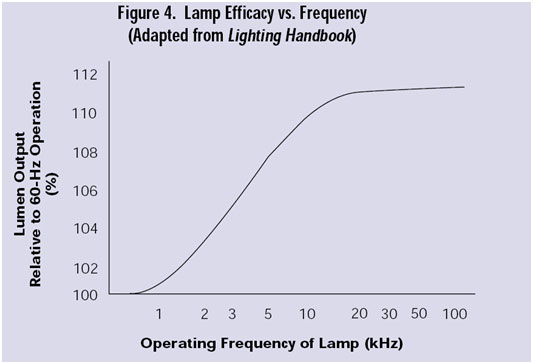

Fig. 5: A Graph Representing Increase in Operational Efficiency of a Lamp

Performance Parameters

Issues with Electronic Ballasts

Advantages

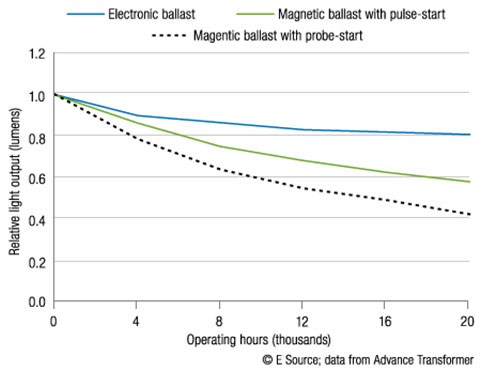

Fig. 6: A Plot Comparing Operational Performance of an Electronic and Magnetic Ballast

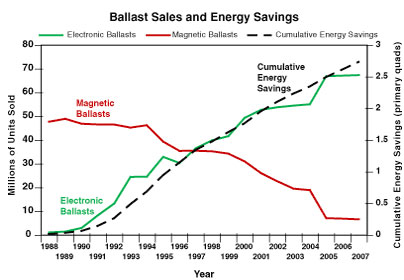

Fig. 7: A Satistical Representation of Increase in Sales of Electronic Ballasts and Reduction in Sales of Magnetic Ballasts

Filed Under: Articles

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.