[[wysiwyg_imageupload:2196:]]This project report is presented by Mr. Shailesh Tank from Sarvajanik College of Engineering & Technology, Surat.

1. Introduction

1.1 Aim of the project

· To move a platform of embroidery machine as per embroidery design specified by the user.

1.2 Source of inspiration

The process used to tailor, patch, mend and reinforce cloth fostered the development of sewing techniques, and the decorative possibilities of sewing led to the art of embroidery.

Before computers were affordable, most embroidery was completed by punching designs on paper tape that then ran through an embroidery machine. One error could ruin an entire design, forcing the creator to start over.

In few year ago the embroidery was done with hands which was time consuming process. It also required more man power and also production is also very less. We have to compromise with quality of embroidery work also.

Now there have been improvements in this machines compare to older ones because of new technologies are added into this.

There are two main types of machine embroidery. The first, free-motion sewing machine embroidery, uses a basic zigzag sewing machine. The second, computerized machine embroidery, uses an embroidery machine or sewing/embroidery machine.

Most modern embroidery machines are computer controlled and specifically engineered for embroidery. Industrial and commercial embroidery machines and combination sewing-embroidery machines have a hooping or framing system that holds the framed area of fabric taut under the sewing needle and moves it automatically to create a design from a pre-programmed digital embroidery pattern.

Depending on its capabilities, the machine will require varying degrees of user input to read and sew embroidery designs. Sewing-embroidery machines generally have only one needle and require the user to change thread colors during the embroidery process. Multi-needle industrial machines are generally threaded prior to running the design and do not require re-threading. These machines require the user to input the correct color change sequence before beginning to embroider. Some can trim and change colors automatically.

A multi-needle machine may consist of multiple sewing heads, each of which can sew the same design onto a separate garment concurrently. Such a machine might have 20 or more heads, each consisting of 15 or more needles. A head is usually capable of producing many special fabric effects, including satin stitch embroidery, chain stitch embroidery, sequins, appliqué, and cutwork.

So we are interested to know about invention and improvements in embroidery machines and how it work.

1.3 Introduction to automation in embroidery machine

Figure 1 Embroidery Machine

The above shown figure is embroidery machine. The embroidery platform is able to move in X-axis and Y-axis directions, X-axis stepper motor drives the embroidery platform in a X-axis direction, and Y-axis stepper motor drives the embroidery platform in a Y-axis direction, a control unit for controlling an operation of both stepper motors, and a control panel used for inputting and displaying information related to embroidery work and embroidery. Worker simultaneously controls the head without changing the position of worker, facilitating the embroidery work.

There are two main types of Machine Embroidery:

The first “Free Motion Sewing Machine Embroidery”, involves using a basic zigzag sewing machine.

The second “Computerized Machine Embroidery” involves using an embroiderymachine or sewing/embroidery machine.

Finally, the embroidery machine is started and monitored. For commercial machines, this process is more automated than for the home machines. Many designs require more than one color and may involve additional processing for appliqués, foam, or other special effects. Since home machines only have one needle, every color change requires the user to cut the thread and change the color manually. In addition, most designs have one or more jumps that need to be cut. Depending on the quality and size of the design, sewing a design file can require anywhere from a few minutes to over an hour.

Basics of Embroidery Machine

2.Basics and literature of embroidery machine

2.1 Block Diagram

Figure 2 Block diagram of working of embroidery machine

Figure 2 Block diagram of working of embroidery machineThe block diagram gives overall idea about working of basic embroidery machine.

As shown in diagram, first of all we give embroidery design to the pc. Now pc will be connected to the microcontroller serially, so it will transfer given design format to the microcontroller in the format which microcontroller can understand.

Microcontroller is connected with stepper motor through motor driver ULN2003A IC which will drive stepper motor according to design format.

At last the platform is connected with both the stepper motor which is movable in both X and Y direction.

2.2 Literature survey

In literature survey we have studied basically following:

Embroidery design format.

- Stepper motor interfacing with microcontroller.

- Computer to microcontroller serial communication. and

- Also about some mechanical systems which is helpful to design two direction platform movement. The various sessions are described as below.

2.2.1 Understanding literature related to design format

Wilcom embroidery design software accepts embroidery pattern from paper or given design and after that it makes design in compatible formats for machines specifically in .EMB format.

After that it converts .EMB format file into .DST format file. Now the microcontroller/computer connected with machine, reads this .DST format file and run the stepper motor accordingly.

Embroidermodder is a free software tool, allows custom modifications to embroidery designs. Reads/Writes .DST file format, which is compatible with most of commercial and vendor’s software available. Also reads/writes Excel .CSV file format for hand editing using Excel or a text editor.

A comma-separated values or character-separated values (CSV) file is a simple text format for a database table. Each record in the table is one line of the text file. Each field value of a record is separated from the next by a character (typically a comma, but some European countries use a semi-colon as a value separator instead). Implementations of CSV can often handle field values with embedded line breaks or separator characters by using quotation marks or escape sequences. CSV is a simple file format that is widely supported, so it is often used to move tabular data between different computer programs that support the format. For example, a CSV file might be used to transfer information from a database program to a spreadsheet.

2.2.1.1 What is CSV?

CSV stands for Comma Separated Values, sometimes also called CommaDelimited. A CSV file is a specially formatted plain text file which stores spreadsheet or basic database-style information in a very simple format, with one record on each line, and each field within that record separated by a comma. It’s important that the individual “records” within a CSV file NOT contain commas, as this may break the simple formatting when using the file in another application.

CSV files are often used as a simple way to transfer a large volume of spreadsheet or database information between programs, without worring about special file types. For example, transferring a home-made address book from Excel into a database program such as Filemaker Pro could be done by exporting the file as a CSV from Excel, then importing that CSV into Filemaker.

2.2.1.2 Converting spreadsheet data to CSV format

- Open your spreadsheet document and go to the File pull-down menu (or the Windows/Office round button menu in Office 2007), and choose Save As….

- Change the “Save as type” or “Format” field to read: “CSV (Comma delimited)”.

- Enter a name for the document and click Save.

- To check the validity of your CSV file, open the new file from a plain-text reading program such as Notepad or TextEdit. Check to make sure there are no extra commas, other than between fields. Depending on what program you’re going to use the CSV file with, you may need to also remove any extra quotation marks or other formatting which Excel may have inserted.

2.2.1.3 Technical background

A file format is a particular way to encode information for storage in a computer file. Particularly, files encoded using the CSV format are used to store tabular data. The format dates back to the early days of business computing and is widely used to pass data between computers with different internal word sizes, data formatting needs, and so forth. For this reason, CSV files are common on all computer platforms.

CSV is a delimited text file that uses a comma to separate values (many implementations of CSV import/export tools allow other separators to be used). Simple CSV implementations will not allow field values that contain a comma or other special characters such as newlines. More sophisticated CSV implementations permit commas and other special characters in a field value. Many implementations use ” (double quote) characters around values that contain reserved characters (such as commas, double quotes, or newlines); embedded double quote characters may be represented by a pair of consecutive double quotes. (Creativyst 2010) Some CSV implementations may use an escape character such as a backslash to encode reserved characters as an escape sequence.

In computer science terms, a CSV file is a “flat file”.

2.2.1.4 Application support

Main article: CSV application support

The CSV file format is very simple and supported by almost all spreadsheets and database management systems. Many programming languages have libraries available that support CSV files. Even modern software applications support CSV imports and/or exports because the format is so widely recognized. In fact, many applications allow .csv-named files to use any delimiter character.

Microsoft Excel will open .csv files, but depending on the system’s regional settings, it may expect a semicolon as a separator instead of a comma, since in some languages the comma is used as the decimal separator.

When pasting text data into Excel, the tab character is used as a separator: If you copy “hello<tab>goodbye” into the clipboard and paste it into Excel, it goes into two cells. “hello,goodbye” pasted into Excel goes into one cell, including the comma.

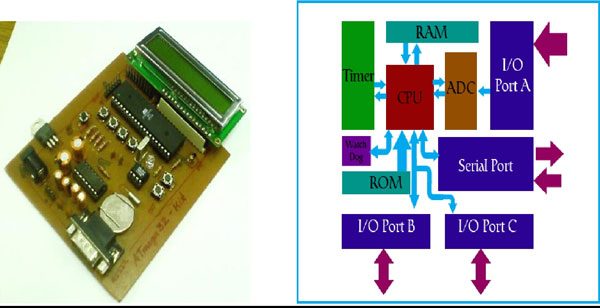

2.2.2 Microcontroller kit

Figure 3 Microcontroller kit

A microcontroller (sometimes abbreviated µC, uC or MCU) is a small computer on a single integrated circuit containing a processor core, memory, and programmable input/output peripherals. Microcontrollers are designed for embedded applications, in contrast to the microprocessors used in personal computers or other general purpose applications.

Microcontrollers are used in automatically controlled products and devices, such as automobile engine control systems, implantable medical devices, remote controls, office machines, appliances, power tools, and toys. By reducing the size and cost compared to a design that uses a separate microprocessor, memory, and input/output devices, microcontrollers make it economical to digitally control even more devices and processes.

A micro-controller is a single integrated circuit, commonly with the following features:

central processing unit – ranging from small and simple 4-bit processors to complex 32- or 64-bit processors

discrete input and output bits, allowing control or detection of the logic state of an individual package pin

serial input/output such as serial ports (UARTs)

other serial communications interfaces like Serial Peripheral Interface and Controller Area Network for system interconnect

peripherals such as timers, event counters, PWM generators volatile memory (RAM) for data storage

ROM, EPROM, EEPROM or Flash memory for program and operating parameter storage

clock generator – often an oscillator for a quartz timing crystal, resonator or RC circuit

2.2.3 Stepper motor

Refer to the tutorial Stepper Motor

Basics of Embroidery Systems

2.2.4 Serial communication

Serial communication is often used either to control or to receive data from an embedded microprocessor. Serial communication is a form of I/O in which the bits of a byte begin transferred appear one after the other in a timed sequence on a single wire. Serial communication has become the standard for inter computer communication. In this lab, we’ll try to build a serial link between 8051 and PC using RS232.

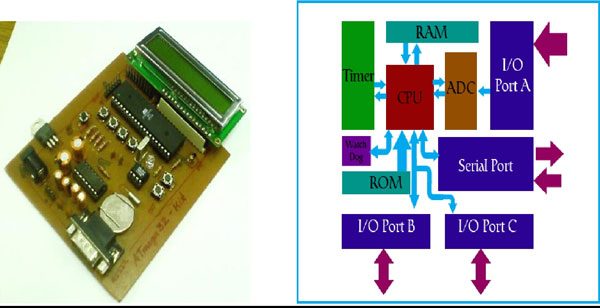

2.2.4.1 Block diagram of serial communication with 8051

Figure 5 Block diagram of serial communication between PC and 8051

Figure 5 Block diagram of serial communication between PC and 8051

2.2.4.2 Standard of RS232

· Most widely used serial I/O interfacing standard

· Input and output voltage levels are not TTL compatible

· 1 bit is represented by -3 to -25 V

· 0 bit is +3 to +25 V

· -3 to +3 is undefined

· To connect RS232 to a microcontroller system must use voltage converters such as MAX232 to convert the TTL logic levels to the RS232 voltage levels, and vice versa

2.2.4.3 Max232 chip

· MAX232 converts from RS232 voltage levels to TTL voltage levels.

· MAX232 has two sets of line drivers for transferring and receiving data.

· Line drivers used for TxD are called T1 and T2.

· Line drivers for RxD are designated as R1 and R2.

· T1 and R1 are used together for TxD and RxD of the 8051.

2.2.4.4 Selection of baud rate in 8051

– Baud rate in the 8051

– Serial communications of the 8051 with the COM port of the PC. It must make sure that the baud rate of the 8051 system matches the baud rate of the PC’s COM port. – We can use Windows HyperTerminal program.

2.2.4.5 Different registers use for serial communication

1. SBUF (serial buffer) register

– a byte of data to be transferred via the TxD line must be placed in the SBUF register

– SBUF holds the byte of data when it is received by the RxD line – can be accessed like any other register

MOV SBUF, #’D’ ; load SBUF=44H, ASCII for ‘D’

MOV SBUF, A ; copy accumulator into SBUF

MOV A, SBUF ; copy SBUF into accumulator

– when a byte is written, it is framed with the start and stop bits and transferred serially via the TxD pin

– when the bits are received serially via RxD, it is deframe by eliminating the stop and start bits, making a byte out of the data received

2. SCON (serial control) register

To program the start bit, stop bit, and data bits.

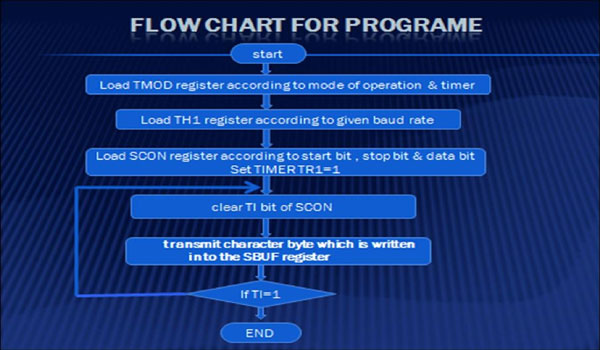

Program to transfer letter “A” serially at 4800 baud, continuously

2.2.4.6 Importance of the TI flag

– Check the TI flag bit, we know whether can transfer another byte.

– TI flag bit is raised by the 8051.

– TI flag cleared by the programmer.

– Writing a byte into SBUF before the TI flag bit is raised, may lead to loss of a portion of the byte being transferred

2.2.4.7 DB 9-Pin connector description

2.2.5 Survey for platform of embroidery machine

Automatically convert simple digital images and artwork into your choice of complex fill, cross-stitch, appliqué, or combination complex fill/appliqué embroidery designs:

• Easy to follow wizards guide you through the design creation step-by-step

• Merge a pre-digitized design with your newly-created design from one of the four wizards: Auto-Digitizer, Cross-Stitch, Appliqué, or Add Motif

• Open artwork files in your preferred graphic editing program for any touch-up before using the wizards

• Add unique style to your applique by using one of 301 icon designs or 188 decorative stitches as your appliqué stitch. Choose from a variety of borders including satin stitch, e-stitch, even shamrocks and stars!

• Design your own border or appliqué shapes or use any of the 40 built-in shapes

• Use the Magic Wand to instantly apply an appliqué to an entire design or portions of a design, creating multiple appliqués within the same design

• Re-sequence the stitching order of color segments

• Choose a cross-stitch size of 10 to 20 per inch so designs match perfectly with your Aida fabric

• Adjust the graphic file size to meet the size you want the finished embroidery design

• Supports a variety of digital artwork formats

2.3 Existing methodology

Machine embroidery in progress.

The basic steps for creating embroidery with a computerized embroidery machine are as follows:

purchase or create a digitized embroidery design file

edit the design and/or combine with other designs (optional) load the final design file into the embroidery machine stabilize the fabric and place it in the machine

start and monitor the embroidery machine

2.3.1 Design files

Digitized embroidery design files can be either purchased or created with industry-specific embroidery digitizing software. Embroidery file formats broadly fall into two categories. The first, source formats, are specific to the software used to create the design. For these formats, the digitizer keeps the original file for the purposes of editing. The second, machine formats, are specific to a particular brand of embroidery machine. Here, the files are available for use with particular embroidery machines and are not easily edited or scaled.

Embroidery machines generally have one or more machine formats specific to their brand. However, some formats such as Tajima’s .dst, Melco’s .exp/.cnd and Barudan’s .fdr have become so prevalent that they have effectively become industry standards and are often supported by machines built by rival companies.

Machine formats generally contain primarily stitch data (offsets) and machine functions (trims, jumps, etc.) and are thus not easily scaled or edited without extensive manual work.

Many embroidery designs can be downloaded in popular machine formats from embroidery web sites. However, since not all designs are available for every machine’s specific format, some machine embroiderers use conversion programs to convert from one machine’s format file to another, with various degrees of reliability.

A person who creates a design is known as an embroidery digitizer or puncher. A digitizer uses software to create an object-based embroidery design,which can be easily reshaped and edited. These files retain important information such as object outlines, thread colors, and original artwork used to punch the designs. When the file is converted to a stitch file, it loses much of this information, rendering editing difficult or impossible.

Software vendors often advertise auto-punching or auto-digitizing capabilities. However, if high quality embroidery is essential, then industry experts highly recommend either purchasing solid designs from reputable digitizers or obtaining training on solid digitization techniques.

2.3.2 Editing design

Once a design has been digitized, an embroiderer can use software to edit it or combine it with other designs. Most embroidery programs allow the user to rotate, scale, move, stretch, distort, split, crop, or duplicate the design in an endless pattern. Most software allows the user to add text quickly and easily. Often the colors of the design can be changed, made monochrome, or re-sorted. More sophisticated packages allow the user to edit, add, or remove individual stitches. Some embroidery machines have rudimentary built-in design editing features.

Loading the design

After editing the final design, the file is loaded into the embroidery machine. Different machines require different formats. The most common home design format is PES. Other common design file formats for the home and hobby market include ART, PES, VIP, JEF, SEW, and HUS. Embroidery patterns can be transferred to the computerized embroidery machines through cables, CDs, floppy disks, USB interfaces, or special cards that resemble flash or compact cards.

Stabilizing the fabric

To prevent wrinkles and other problems, the fabric must be stabilized. The method of stabilizing depends on the type of machine, the fabric type, and the design density. For example, knits and large designs typically require firm stabilization. There are many methods for stabilizing fabric, but most often one or more additional pieces of material called stabilizers or interfacing are added beneath or on top of the fabric, or both. Stabilizer types include cut-away, tear-away, vinyl, nylon, water-soluble, heat-n-gone, peel and stick, and open mesh, sometimes in various combinations.

For smaller embroidered items, the fabric is placed in a hoop, which is attached to the machine. A mechanism called an arm moves the hoop under the needle.

2.3.3 Embroidering the design

Finally, the embroidery machine is started and monitored. For commercial machines, this process is more automated than for the home machines. Many designs require more than one color and may involve additional processing for appliqués, foam, or other special effects. Since home machines only have one needle, every color change requires the user to cut the thread and change the color manually. In addition, most designs have one or more jumps that need to be cut. Depending on the quality and size of the design, sewing a design file can require anywhere from a few minutes to over an hour.

Design

3. Design

3.1 Hardware design

3.1.1 Technique of stepper motor interfacing

See the project Interfacing Stepper Motor

3.1.3 Platform design

Platform is important part of project. Through it we can obtain required output design.

Figure 8 Platform design

We need to connect pulley to stepper motor. Through it we can get required linear motion. Pulley will convert rotary motion of platform into linear motion. Thus platform will be moved linearly. We need to move platform in two directions and for that we require two stepr motor connected with pulley

3.1.4 Selection of components

Motor driver

Following are the criteria’s to select motor driver IC:

- Variable speed of motor.

- Constant speed motor.

- Fixed speed and reduced current motor.

If an application requires the motor to operate at a constant speed with little or no stopping and starting at full voltage, you will most likely required an electromechanical motor starter.

If an application requires intermediate starting and stopping of the motor, you may need of a solid state reduced current inrush motor starter. A reduce current motor starter function by decreasing the starting current to the motor during start-up , allowing to the motor ramp up to full speed.

In order to save energy and running motor at variable speeds can optimize a process by using variable speed driver.

3.1.5 Alternative components

Motors:

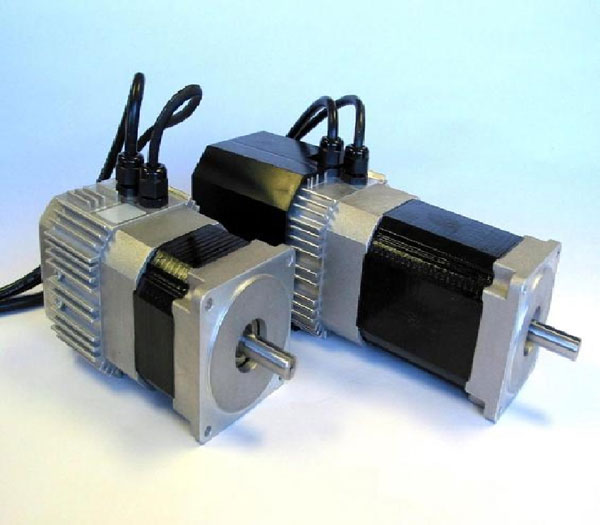

1) Servo Stepping Motor or Stepping Servo Motor

Stepping motor is open loop motion control unit most of the time. How could we fulfill high speed, closed loop where there is feedback from the motors by using stepping motor instead of servo motor? As you know, an encoder or a sensor is needed for simple stepping motor movement feedback system. UIrobot CANBus stepper controller baud rate reach 112500 bps, that means you run a stepping motor under 16th micro steppers resolution the speed of the motor could reach 2100rpm. UIrobot CANBus stepper controller is going to open two terminals for sensors. All of this is going to be done to satisfy customer’s servo stepping motor needs.

Figure 9 Servo motor

Figure 9 Servo motor

2) Mona sewing machine motor with regulator

· Single phase

· High speed F.H.P Motor 1/12 H.P AC/DC

· Suitable for domestic and industrial sewing machines

· RPM: 6500

· W: 65W.

Figure 10 Motor with regulator

Figure 10 Motor with regulator3) Integral clutch motor:

– Mona Clutch Motors are built with the most advanced technology

– Simple, Economical, Durable and Rugged to operate and maintain.

– Suitable for Indian & imported sewing machines used in ready made & leather industries.

– Models Available: 200W (1/4 H.P.), 250W ( 1/3 H.P.), 400W (1/2 H.P. ), 560W (3/4 H.P.), 750W (1H.P.) Single phase/ Three phase, 1440/2850 R.P.M.

Figure 11 Integral clutch motor

Motor drivers:

1) Low voltage coil motor driver (A3904)

Features

Fixed I2C logic thresholds 8-bit D-to-A converter 500 µA resolution

Low voltage I2C serial interface Low current-draw sleep mode 2.4 to 5.5 V operation

1.1 mm × 0.7 mm, 0.5 mm maximum overall height WLCSP

Figure 12 Low voltage coil motor driver (A3904)

2) Automative three phase BLDC controller and MOSFET driver (A3930 and A3931)

Features

High current 3-phase gate drive for N-channel MOSFETs

Cross-conduction protection

Integrated commutation decoder logic

Extensive diagnostics output

Low-current sleep mode

Figure 13 Automative three phase BLDC controller and MOSFET driver

Figure 13 Automative three phase BLDC controller and MOSFET driver

3.2 Software design

We have used basically 4 softwares:

1. Keil

2. Proteus

3. Embroidermodder

4. Matlab.

3.2.1 Keil

Keil was founded in 1986 to market add-on products for the development toolsprovided by many of the silicon vendors. Keil implemented the first C compiler designed from the ground-up specifically for the 8051 microcontroller.

Keil provides a broad range of development tools like ANSI C compiler, macr assemblers, debuggers and simulators, linkers, IDE, library managers, real-time operating systems and evaluation boards for 8051, 251, ARM, and XC16x/C16x/ST10 families.

3.2.2 Proteus

Proteus is software for microprocessor simulation, schematic capture, and printed circuit board (PCB) design. It is developed by Labcenter Electronics.

3.2.2.1 System components

ISIS Schematic Capture – a tool for entering designs.

PROSPICE Mixed mode SPICE simulation – industry standard SPICE3F5simulator combined with a digital simulator.

ARES PCB Layout – PCB design system with automatic component placer, rip-upand retry auto-router and interactive design rule checking.

VSM – Virtual System Modeling lets co simulate embedded software for popularmicro-controllers alongside hardware design.

System Benefits Integrated package with common user interface and fully contextsensitive help.

3.2.3 Embroidermodder

3.2.3.1 What is it?

Embroidermodder is a free software tool that allows the user to add custom modifications to the embroidery designs.

3.2.3.2 Features

Reads/Writes Tajima .DST file format, which is compatible with most every commercial and vendor’s software available.

Also reads/writes Excel .CSV file format for hand editing using Excel or a text editor.

Allows scaling designs to any size (not just +/- 20% like some software). Shows the design on-screen, with unlimited zoom to get up close and personal with any stitch. Zoom to actual size, fit to screen, selection, or just in/out. Scrollbars allow panning around the design.

Multiple documents can be open, and each document may have multiple view windows, each at different zooms to allow fine detail editing, while still getting the big picture.

Displays statistics like max/min/average stitch length, number of colors, etc. Select, move, insert, or delete either stitches, lines, or selection.

Double click in select mode to select a region (stitches between Jumps or color changes).

Cut/Copy/Paste selection

Display updates are very fast using a combination of direct screen draw with efficient clipping and background rendering.

Optional Debug mode (compile time option) with additional display and break capability, such as monitoring the background render progress in the status bar.

3.2.4. Matlab

MATLAB (matrix laboratory) is a numerical computing environment and fourth-generation programming language. Developed by MathWorks, MATLAB allows matrix manipulations, plotting of functions and data, implementation of algorithms, creation of user interfaces, and interfacing with programs written in other languages, including C, C++, Java, and Fortran.

Although MATLAB is intended primarily for numerical computing, an optional toolbox uses the MuPAD symbolic engine, allowing access to symbolic computing capabilities. An additional package, Simulink, adds graphical multi-domain simulation and Model-Based Design for dynamic and embedded systems.

In 2004, MATLAB had around one million users across industry and academia. MATLAB users come from various backgrounds of engineering, science, and economics. MATLAB is widely used in academic and research institutions as well as industrial enterprises.

PROGRAM:

Disp (‘line – 1’)

Disp (‘line – 2’)

Disp (‘line – 3’)

n= input (‘enter your choice ‘)

a=17+n;

b= dec2hex (a);

fprintf (s2,’%c’,b)

3.3 Design Logic

Different steps given to the stepper motor for a particular design are shown here. They are as follows:

Linear Line:

|

Sr no.

|

Motor 1

|

Motor 2

|

|

1

|

0C

|

00

|

|

2

|

00

|

0C

|

|

3

|

06

|

00

|

|

4

|

00

|

06

|

|

5

|

03

|

00

|

|

6

|

00

|

03

|

|

7

|

09

|

00

|

|

8

|

00

|

09

|

|

Similarly we can repeat above steps until we get line of expected length.

|

||

|

Square

|

|

|

|

|

|

|

|

Sr no.

|

Motor 1

|

Motor 2

|

|

1

|

0C

|

00

|

|

2

|

06

|

00

|

|

3

|

03

|

00

|

|

4

|

09

|

00

|

|

5

|

00

|

0C

|

|

6

|

00

|

06

|

|

7

|

00

|

03

|

|

8

|

00

|

09

|

|

9

|

03

|

00

|

|

10

|

06

|

00

|

|

11

|

0C

|

00

|

|

12

|

09

|

00

|

|

13

|

00

|

03

|

|

14

|

00

|

06

|

|

15

|

00

|

0C

|

|

16

|

00

|

09

|

We can repeat steps 1 to 4 after 4th if we want square of greater size, for it we also have to repeat steps 5 to 8 after 8th and so on.

Triangle:

|

Sr no.

|

Motor 1

|

Motor 2

|

|

1

|

0C

|

00

|

|

2

|

06

|

00

|

|

3

|

03

|

00

|

|

4

|

09

|

00

|

|

5

|

00

|

0C

|

|

6

|

03

|

00

|

|

7

|

00

|

06

|

|

8

|

06

|

00

|

|

9

|

00

|

03

|

|

10

|

0C

|

00

|

|

11

|

00

|

09

|

|

12

|

09

|

00

|

|

13

|

03

|

00

|

|

14

|

00

|

03

|

|

15

|

06

|

00

|

|

16

|

00

|

06

|

|

17

|

0C

|

00

|

|

18

|

00

|

0C

|

|

19

|

09

|

00

|

|

20

|

00

|

0

|

Similarly we can develop logic for some other design also.

4. RESULTS AND WORK SCHEDULE

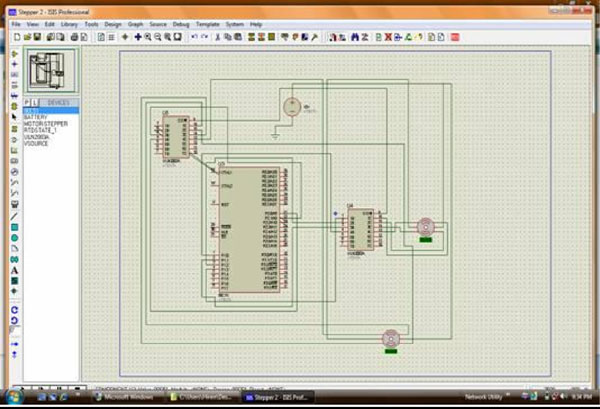

4.1 Simulation of two stepper motor

Figure 14 Simulation of two stepper motor

Figure 14 Simulation of two stepper motor

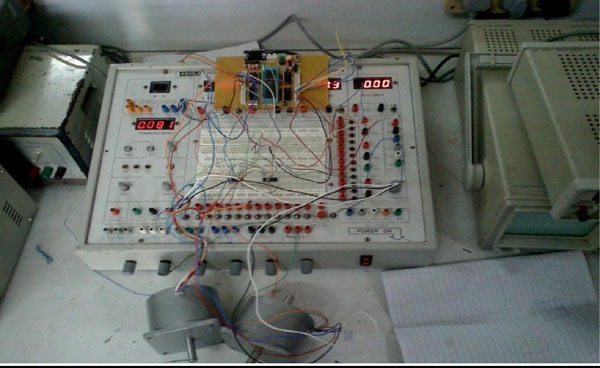

4.2 Implementation of two stepper motor interfacing with 8051

Figure 15 Implementation of two stepper motor interfacing with 8051

Figure 15 Implementation of two stepper motor interfacing with 8051

4.3 Implementation of serial communication

Figure 16 Implementation of serial communication

4.4 Output of serial communication

Figure 17 Output of serial communication

Figure 17 Output of serial communication

4.5 Work done in odd semester

1. .CSV design format study.

2. Simulation of two Stepper motor interfacing with microcontroller in proteus

3. Implementation of stepper motor interfacing

4. Serial communication (Transmit data from microcontroller to pc)

5. Platform mechanism

4.6 Work done in even semester

1. Using PC and Microcontroller, transfer design to microcontroller , analyze embroidery design at Microcontroller level and also Offers controls to platform X-Y motors.

2. To do platform mechanism which will move in two directions.

3. Using Microcontroller, accept design by microcontroller , directly may be through USB, analyze embroidery design at Microcontroller level and also Offers controls to platform X-Y motors. (If time permits)

5. Industrial visit

5.1 Basic parts of embroidery machine:

5.1.1 Electronic motor starter

Specifications:

Company name: Gelco

Power supply: 415V, 3Ph, 50Hz, AC

Model no.: GTW 303

5.1.2 Mother board

It can also be known as heart of embroidery machine.

It connects with computer, heads and beam card

5.1.3 Computer (Human machine interface (HMI))

Figure 18 Human machine interface

Figure 18 Human machine interface![]()

It is mainly used to enter design of various kind.

We can enter any design which we want on that particular piece of material.

It is connected with mother board.

Read more about Human Machine Interface (HMI).

5.1.4 Beam card

Figure 19 Beam card

Figure 19 Beam cardIt is situated at one side of machine.

It connects all heads of machine.

5.1.5 Compressor

It connects with all the heads.

It is used for the relative motion of the needle.

5.1.6 Other small parts

5.2 Sequin cassette maker

Cost: 1 lac Rs.

Dye cost: 45000 Rs.

It includes length counter and speed sensor

6. Conclusion

From the given project we can conclude that stepper motor runs according to given design formats, but still platform is not giving exact response to the given design format due to friction problem in it. Stepper motor gives output in terms of steps so jerk produce to the platform. This problem is solved if we used servo motor.

Project Source Code

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.