Robots got their name from a Czech word “Robota” which means slave or any mechanical item that can help its master. Robots are mechanical devices that help to perform specific tasks for the humans. The term ‘Robot’ can be used for any mechanical device equipped with the software-based intelligence to perform specific physical tasks. The design of a robot basically involves three functionalities –

1) Sensing –

A robot must be capable of sensing the environment with the help of external sensors. For sensing, various types of sensors that can read physical quantities like temperature, light intensity, Infrared radiation or others depending upon the application of the robot or sensors for robotic vision, touch sensitivity, voice recognition, proximity sensing must be attached to electronic circuitry controlling the robot.

2) Decision Making –

The robots are useless without software-based intelligence and capability to make decisions. They must be able to sense the environment and make decisions based on that so that the tasks ascribed them could be performed. For decision making the control circuitry of a robot may have a programmable controller, microprocessor or a mini computer.

3) Performing –

The robots are designed to perform physical tasks. For that, they have actuators, motors and drive systems attached to their mechanical assembly. These actuators and motors are controlled programmatically by the control circuitry.

The robotic cars or robotic vehicles are one of the many robotic designs which are developed to move around for performing physical tasks. The motion of such robot itself involves the application of power and use of motors. In making such a robot, there needs to be a balance between the load (weight of Robot), Battery and Motor used. These three elements are connected with each other and choosing the right one needs a lot of mathematics and experimentation. Like in the previous tutorial, it was discussed how to choose a right motor for a robotic application, in this tutorial, how to choose a suitable battery for the selected motor according to the load is determined.

Before learning about the types of battery let us first have a look at basic specifications of batteries.

Specifications of Batteries –

In the previous tutorial, basic specifications of the dc motor were discussed. In order to run a motor in a robot, one needs to choose a battery with proper specifications. There are many kinds of batteries that are available for powering the motors. The main specifications that should be taken into consideration for selection of a battery are as follow –

Voltage Rating – It is the maximum terminal voltage, a new battery is expected to deliver to the electronic components.

Current Rating or Capacity Rating – The amount of current, a battery can deliver in an hour is called its current rating or capacity rating. This rating is associated with the power the battery can deliver. Like, a battery with a capacity of 1 amp-hour will be able to continuously supply a current of 1 amp to a load for exactly 1 hour, or 2 amps for 1/2 hour, or 1/3 amp for 3 hours, etc., before getting completely discharged.

For example, an average automotive battery might have a capacity of about 70 amp-hours, specified at a current of 3.5 amps. This means that the amount of time this battery could continuously supply a current of 3.5 amps to a load would be 20 hours (70 amp-hours / 3.5 amps).

C and E Rates – The discharge current is often expressed as C – rate in order to normalize the battery capacity. 1C means that discharge current will discharge the battery in an hour. A 5C rate for this battery then would be 500 Amps, and a C/2 rate would be 50 Amps. Similarly, an E-rate describes the discharge power. A 1E rate is the discharge power to discharge the entire battery in 1 hour.

Let’s now move on to the types of batteries available for use in robotic projects. There are the following types of batteries available for use in robots –

Alkaline Battery – Alkaline batteries are non–rechargeable batteries that come with 1.5 V and 9V ratings. The 1.5 V battery comes in different varieties such as AA (around 1000 mAh), AAA (less than 1000 mAh), C (2000 mAh to 2500 mAh) and D (Around 2000 mAh). The 9V battery comes in 50 to 500 mAh range. These batteries are low-cost and readily available but it does not last long and discharges quickly.

Fig. 1: Representational Image of an Alkaline Battery

Nickel-Metal Hydride Batteries (Ni-MH) – Ni-MH batteries are rechargeable, where the voltage rating of the each cell is 1.2 V that comes with range from 600 mAh to 3300 mAh. These batteries are a bit costlier but they last longer and have a high current capacity.

Fig. 2: Nickel -Metal Hydride Battery

Lead-Acid/SLA Batteries –

The SLA batteries are still the cheapest option for high capacity. They require almost no maintenance for several years and can undergo a thousand of charge and discharge cycles until the discharge is no more than 30% of their capacity. In addition, the SLA batteries can output tons of current and are easy to charge. These batteries are widely available in low-cost, but these batteries are like heavy boulders for mobile robots and are not preferred for the hobby robots.

Fig. 3: Picture Showing Acid-Lead Batteries

Lithium-Ion Batteries (LI-Ion) – Lithium-ion batteries are rechargeable batteries which are same as used in mobile phones and cameras. Li-Ion batteries come with 3.7 V rating. These batteries are easily available and have high capacity. They are also lightweight.

Fig. 4: Image of a Lithium-Ion Battery

Lithium Polymer Batteries (Li-Po) – These are becoming the most popular type of batteries for use in robotics because of their lightweight, high discharge rates and relatively good capacity, except the voltage ratings are available in increments of 3.7 V.

Fig. 5: Lithium Polymer Battery

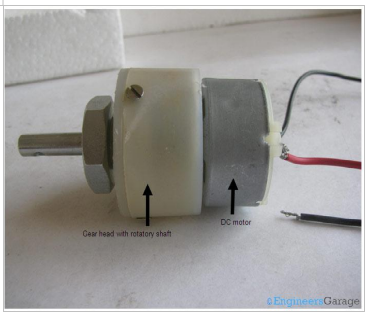

For matching a battery with a motor, the specifications of motors should also be known. The DC motors used in robotics are mostly the geared ones. The geared DC motors have the geared mechanism that slows down the motor speed and increases the torque. The following specifications of the geared DC motors should be taken into consideration –

Voltage Rating – The voltage rating is the maximum sustained voltage that can be safely applied to the DC motor without risking the possibility of the electric breakdown. Suppose if the voltage range of the motor is 5V – 12V that means the motor can be powered between 5V and 12V.

Fig. 6: Graphical Presentation of a DC Battery

Free Current or No Load Current – As the name suggests, the no-load current is the current at which the motor runs freely without any load attached to its shaft. As an unloaded DC motor spins, it generates a backward-flowing electromotive force that resists the current being applied to the motor. The current through the motor drops as the rotational speed increases, and a free-spinning motor has very small current.

Stall Current – Stall torque is the torque which is produced by a device when the output rotational speed is zero. It may also mean the torque load that causes the output rotational speed of a device to become zero to cause stalling. Stalling is a condition when the motor stops rotating. This condition occurs when the load torque is greater than the motor shaft torque i.e. this is breakdown torque condition. In this condition, the motor draws maximum current but the motor does not rotate. This current is called Stalling current.

Power – The power of a motor is generally expressed in watts. The power rating is derived from the simple relation, power = voltage x current. For example, a motor driven at 5V with 100 mA of current drawn, is consuming 0.5 Watts of power.

Torque – The Force directed in the circle is known as torque. As simple it is said to be the amount of weight the dc motor can lift for the given distance.

Choosing a Battery for a given DC Motor

Voltage Rating – While making a hobby robot, there are chances that the robot may have faulty power supply because it may be utilizing a 9V battery in the circuit. The 9V batteries are intended to be used for primarily electronics and not for powering motors because they have a low output current and low capacity. For powering motors, batteries like AA, AAA, D or C or even battery packs are more suited as they are manufactured for a specific voltage rating and configuration.

A 9V battery is actually composed of flat packs in series. These batteries have very tiny capacitances, at most that can be found at 500 mA. These batteries can be used to power up certain electronic components of the robots like the microcontroller and other low power drawing electronics in the robot like sensors. Motors compared to the typical microcontrollers draw many times more power, often into the hundreds of milliamps, and when they stall out (Hold the shaft of the motor still) they can draw several amps, which can drain a 9V battery in few minutes.

Many robots utilize a Motor Driver IC that has supplies for the logic side and the motor side. By connecting 4 AA batteries into the motor side of the controller, the 9V battery or even that same AA pack can be connected to the logic supply as well as the motor supply. But, the motor supply should not be connected to a 9V logic supply. Because, in such case, the logic side may work, but the motor supply may not work.

Type of Battery – NiMH is the most preferred choice for powering the motors because they have decent capacitance, are low-cost compared to their size and have decent current output. Also, NIMH batteries are rechargeable and safe to use in comparison to NICAD batteries. NiMH batteries lack the memory effect and do not contain Cadmium which is a toxic chemical.

Another popular choice nowadays is Lithium Polymer batteries. They are designed to output power many times of their capacitances. Some batteries can output hundreds of amps for a short time. However, Lithium Polymer batteries are dangerous to use and need to be handled carefully. So it best to begin with NIMH batteries first.

Another preferable choice can be Lead Acid Batteries which are made of spongy lead grills with special electrolytes on each plate. Their each cell has a 2V potential. The most common cell configuration is 6 Cells, or 12V. For a large robotic project that requires lots of amps, the Lead Acid battery is the best choice. Lead Acid Batteries have the relatively low-power density for their weight, but they can output hundreds of amps easily for long periods of time and are easily chargeable.

There are also Li-ion batteries that can be used in hobby robots. Li-Ion Batteries are generally used as a camera and Laptop batteries. However, they cannot output large currents at once. That is why Li-Po batteries are given more preference. The Li-Ion and Li-Po batteries are actually very similar but have different cell construction. However Li-ion batteries are best for low current drawing electronics, such as for a robotic controller or sensor circuit. But this excludes motors. Li-Ion batteries are a bit tricky to charge compared to other batteries and that is why still it is better to use a NiMH battery pack over a Li-Ion battery.

Torque and RPM – The torque and RPM of a motor are already known by its specifications. Using Torque, RPM and average efficiency, total Power that the motor needs to move can be calculated.

Let’s represent the total power required by the motor by P.

The total energy required by the motor can be found by the following equation –

E=P*T

Where,

T is time in seconds

E is total energy required

P is Power rating

A factor of 1.2 should be multiplied in the above equation to include power required by other electronics like motor controllers etc and to consider efficiency losses. This is the energy needed to be delivered by the battery. The energy equated from this equation is in Joules, but battery specifications are typically in AH (ampere-hour). So if a 12V motor with a rating of 100 AH is to be powered, total energy required can be equated as follow –

12 * 100 *3600 (seconds in an hour) = 4320000 Joules of energy.

This energy should be more than the energy requirements for all the motors combined. Depending on how much the battery weighs one can increase or decrease the required specifications.

Filed Under: Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.