After yet another interesting day at the office, I reached my room at night. I went straight to my desktop PC. Today I’ve taken some pictures of the new company and I plan to upload it on the internet. I turned the UPS on and waiting for the system boot. I heard a beep sound from somewhere; it’s not from the system but from my mobile phone. Low battery again! Alright; I’ll plug it into the system once it booted. But for my surprise, there is a dialogue in the LCD screen, “no signal”. Perhaps my power cord has broken again. I’m not wasting any time. I’ve another new power cord with me. I removed the damaged one and connected the new power cord and tried again and it works.

Now I’ve my digital camera and my mobile phone in my hand, both of them need to be connected to the system. But I’ve only four USB ports and all of them are in use. I’ve already connected my portable hard disk, data card, mouse and a pendrive. I need two usb ports and I know that I’m not using the portable hard disk and the pendrive at this moment, so I can remove them. I pugged in the digital camera, and my mobile phone. I went online, shared my photos, and did some chatting. After an hour, my mobile phone has full charge. I removed it from the USB port, plugged in my headset and went to bed. That’s the end of the story!

Now just rewind things. I’ve changed the damaged power cord of the PC. Will it be possible if the wire is directly soldered to the mother board? Secondly I’ve removed two devices from the USB port. Can you imagine the USB devices permanently hanging down from the USB port and not removable? Then I plugged in my headset. How will you feel when the long wires of your headset always hanging down from your stylish mobile phone?

THANKS TO CONNECTORS!!

Let’s take a journey to the world of the electrical connectors. What is an electric connector?

It is nothing but a simple, small size electro-mechanical device. It is basically use to connect two or circuits together. It is possible for the circuits to transfer power or signal through the connectors. Connectors have one more metallic structure inside it for electrical connections.

The connectors always provide a temporary connection between the circuits.

his temporary connection has so many advantages over the permanent connections. You can easily replace a particular circuit in a system; you can check the input or output of a circuit independently etc. Moreover the connector provides easy assembling and troubleshooting.

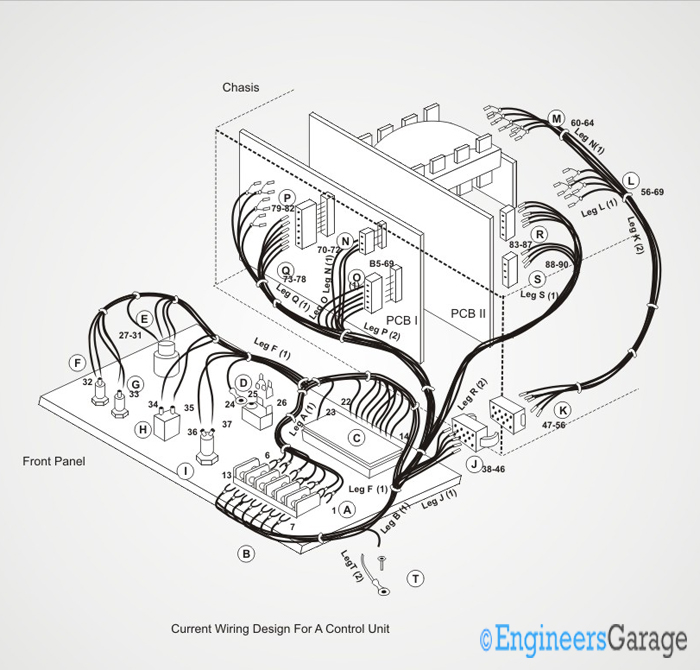

Consider the following figure. How many different connectors are there in the unit? There are different circuit boards and the different circuit boards are assembled together using the connectors to form a control unit. Some connectors are used to connect wire to board, some are used to connect board to boards, some are connected to the power supply etc.

It was of course possible for the designer to assembly the entire circuit in a single board. But what could be the reason that the designer adopted this method? In this method one can easily assembly the circuit. Each board can be separated easily from the unit and tested individually. Most of the cases there is no need to physically separate the board to be tested from the unit, but just remove the connectors from that board. It provides option to upgrade some boards and components and there by improve the performance of the unit whenever possible. Another important thing is that mast of the connectors can be connected together in only one possible method, hence it avoid the possibility of wrong connections.

Fig. 1: Diagram Showing Connectors in Control Unit

Summarizing Connectors

Let’s summarize the points:

Connector is an electro-mechanical device.

Connectors have one more metallic structure inside it for electrical connections.

It provides only temporary connection between circuits.

It allows transfer of power and signals between circuits.

It allows testing circuits in a unit separately.

It helps in troubleshooting.

It helps in easy assembling of a unit.

It provides upgrading the components blocks of a unit.

An electrical connector is basically made of two things, conductors and insulators. Usually there is more than one conducting path for power or signal separated by insulators.

The following are the commonly used conducting materials in an electro-mechanical connector;

Copper:

Copper is the best conductor of electricity and is widely used. It is comparatively cheap as well.

Brass:

Brass is also a good conductor of electricity. The metal is relatively stronger and hence is used in that kind of connectors.

Aluminum:

Aluminum is also a good conductor. It is also very light and cheap.

Silver:

Silver is also used in electro-mechanical connectors, which is a great conductor of electricity. But the metal is very expensive.

An insulator is a kind of material which offers very high resistance to the flow of electric current. They are used in an electro-mechanical connector to physically separate the conducting lines or pins. They are also used as non-conducting covering for the connectors.

The commonly used insulators in electro-mechanical connectors are rubber, plastic and synthetic materials.

A conductor in an electro-mechanical connector conducts electricity and does not offers any resistance, where as an insulator does not conducts electricity and offers infinite resistance. That’s how we define ideal conductor and ideal insulator and it will make an ideal connector. But certainly that is not the case in practical connectors. There is no material which is offers zero resistance or infinite resistance. Every conductor offers a small finite resistance and every insulator offers a finite small conductance. Also the materials’ conducting property varies with the frequency. All these things give certain characteristics to an electro-mechanical connector.

Connector manufactures test these characteristics thoroughly in their lab and mention as electrical specifications in their datasheet.

Now let’s discuss about some of the most common specifications and terms found in an electro-mechanical connector’s datasheet.

Common Electrical Specifications

CONTACT

A contact is nothing but the conducting material which can make a connection with another connector or a wire of its matching type. The connector makes a contact both electrically and mechanically. The contacts are always temporary but are tight enough to keep them together for a very long time without failing in the rough environments.

CONTACT RESISTANCE

In an electro-mechanical connector, the electrical contact is always achieved by physically connecting the conductors together. As we have discusses previously that there is no ideal conductor in this world. Every conductor introduces a small finite resistance into the current flowing path. In connectors also the conducting material in the contact between two or more circuits introduces resistance between them, and we call the maximum value of such resistance as contact resistance. It is measured once the connectors made full contact. It is also called transition resistance.

The resistance can cause voltage drop and also dissipate heat while current flows through it.

Hence this value is very important in the designing of a device especially for high current, high efficiency applications.

The contact resistance’s value depends on the quality of the contact material and geometry of the connector. Normally the electro-mechanical connectors have a contact resistance less than 20milliohms.

INSULATION RESISTANCE

In an electro-mechanical connector both conductors and insulators are used together. As we have discussed already, an insulator never offer infinite resistance to the flow of electric current, but every insulator has a finite maximum resistance. This maximum resistance of an insulator is called insulation resistance. Since insulators are used to separate the metallic contacts from each other, the insulation resistance can also be referred as the resistance between the conductors.

The insulation resistance value is very important in the designing of high voltage applications. Electro-mechanical connectors normally have insulation resistance of the range of thousands of mega ohms.

VOLTAGE DROP

Whenever current flows through a resistance a voltage drop appears across it. The same thing happens in the connectors also. We know that in electro-mechanical connectors, electric current flows through the contact material, and the contact material has a contact resistance. When current flows through the contact a voltage is dropped across this resistance and the maximum value of that voltage at a given current is called voltage drop of a connector.

This value is very significant is the design of low voltage, sensitive devises.

CAPACITANCE

When connectors make contact they not only produce contact resistance but capacitance also. This capacitance appears in between the contact materials. This capacitance is otherwise called stray capacitance. The maximum value of stray capacitance comes in the range of Pico farads.

This capacitance can attenuate high frequency signals, more the value of the capacitance more attenuation it introduces. Hence this value is very important in high frequency applications.

FREQUENCY RANGE

Since there is stray capacitance in the connector, as the frequency of signal increases the attenuation also increases. We can also say that the impedance increases as the frequency increases. There is minimum signal amplitude preferred which is 3dB less than the maximum input signal amplitude. The attenuation should not reduce the signal amplitude below this level. The maximum frequency at which the connector is able to keep the signal level above this level is called frequency range of the connector. Each connector has a specified frequency range and the value is very important in high frequency applications.

RATED VOLTAGE

Rated voltage is otherwise called working voltage. It is the maximum voltage at which the manufacture suggests the designer to use the connector. The connector is designed to operate only up to this maximum voltage. Rated voltage does not specify the voltage waveform, whether AC or DC. Different connector has different working voltage. Operating the connector above the rated voltage may cause permanent damage to the connector.

NOMINAL VOLTAGE

Nominal voltage is the maximum AC voltage at which the connector is designed to operate. Nominal voltage for a sine wave AC waveform which we are getting from the power lines is calculated as 5 to 10 percentage less than the actual maximum voltage or the maximum rated voltage.

RMS voltage for sine wave AC = maximum voltage of sine wave / sqrt(2)

Operating above this maximum rating may cause permanent damage to the connector.

Electrical Specs. Contd.

RATED CURRENT

Rated current is otherwise called working current. It is the maximum current at which the manufacture suggests the designer to use the connector. The connector is designed to operate only up to this maximum current. Rated voltage does not specify the current waveform, whether AC or DC. Different connector has different working current. Operating the connector above the rated voltage may cause permanent damage to the connector.

NOMINAL CURRENT

Nominal current is the maximum AC current at which the connector is designed to operate. Nominal current for a sine wave AC waveform which we are getting from the power lines is calculated as 5 to 10 percentage less than the actual maximum current or the maximum rated current.

RMS current for sine wave AC = maximum current of sine wave / sqrt (2)

Operating above this maximum rating may cause permanent damage to the connector.

AMBIENT TEMPERATURE

It is the maximum temperature at which the device is designed to work in the room environment. Ambient temperature is the temperature experienced by a device in the room conditions. It is otherwise called the working temperature.

Operating the device above this temperature may result in shift of characteristics of the connector which are specified in its datasheet and also may cause damage to the connector.

DIELECTRIC STRENGTH

Dielectric strength is a measurement that is related with the insulating material in a connector. An insulating material behaves like an insulator only up to a certain higher voltage ranges, after that dielectric breakdown occurs and the material suddenly starts conducting electricity like a conductor. Dielectric strength is the maximum voltage up to which the insulating material can keep its insulating property without causing dielectric breakdown.

It is otherwise called Dielectric withstanding voltage, Breakdown voltage, Withstanding voltage, Voltage proof etc.

Operating the connector above this range may cause dielectric breakdown, result in spark and might cause permanent damage to both the connector and the device in which it is connected.

Hence this parameter is very important in high voltage applications.

GENDER

Like animals the connectors are also classified into two on the basis of their sex. There are male and female connectors. Although there are connectors which are exceptions, most of the connectors comes in male and female pairs. We can identify the sex of the connector from the design of the contact. Usually male connectors are designed with pin contacts and female connectors with socket contacts, but there is no such rule. If you think male connector is the one with the pin contact and the other kind is female; well it is not defined anywhere in that manner. It is actually the location, mobility and the usage of the connector that makes it called male or female.

Generally a female connector is screwed into the outer surface of a unit, while the male connector is attached to the wire or a smaller device which is intended to be connected to that unit. Hence the female connector is less mobile and always sits in the unit while the male connector is used where mobility is required. Simply a male connector is referred to as the connector which is brought to make contact with the female connector which has been mounted on a unit.

A male connector is also referred to as Plug or Pin. A female connector is also referred to as Socket or Jack.

A designer is free to choose the sex of the connector in his or her design irrespective of the convention.

MATING CYCLE

The term mating with respect to the connector is the process of connecting a male connector to the female connector. During mating the male and female connector should come in full physical contact with each other. During this process both of the connector suffers slight wear and tear due to pressure and frictional forces. Large number of continuous mating may result in adding up of this wear and tear and cause significant damage to the connectors.

Mating cycle is the maximum number of times the connectors are allowed to mate with each other. Operating the connectors above this maximum value may cause permanent damage to both the connectors result in loose contact, spark or other problems.

PIN ORIENTATION

A connector can have more than one contacts separated by the insulators. The arrangement of these contacts inside a connector is referred to as the pin orientation. It can be also defined in terms of the numbering of the pin and their respective positions; for example in a 3 pin connector the pin number 1 is on the left hand side while the pin number 2 is on the right hand side and pin number 3 could be at the center of the connector.

The designer should be careful about the pin orientation while connecting wires, designing PCB etc.

PIN-OUT

Pin-out is the most important thing as far as a product design is concerned. It is usually referred to the protocol based connectors, which we will discuss later in this article. In most of the connectors each contact pins is assigned a certain function; for example pin 1 should be used for connecting VCC, pin 3 should be used for connecting ground and pin 2 should be used only to carry signal. These details are mentioned in the datasheet of the connector as pin-out.

The designer should have a good knowledge about the pin-out of the connector for the proper functioning of the device.

POLARIZATION

Most of the connector can be connected in only one orientation as they have keys or notch like matched structures on both the male and female connectors of the same type. This eliminates the chances of connecting the wrong pin of the male connector to a female connector’s receptacle.

One should be very careful about the orientation while designing the board or panel especially in case of the female connector which are generally screwed on to the device.

Filed Under: Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.