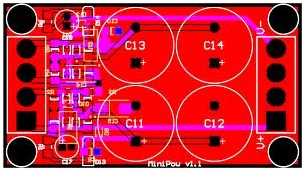

Different kinds of PCB design software’s are available in market and according the requirement different users used different software. Like I am comfortable in designing my PCB on Eagle and my vendors who fabricate the PCB does not have Eagle than what will happen?

Hence to bridge the gap between the PCB designer and manufacture we use gerber file. Gerber file contain information about the PCB like what will be the pad size, drill size, name of component etc. With the help of gerber file information obtained and manufacture feed the data into their machinery to manufacture PCB. The most common format that is used today is RS-274-X. But before using always check with the board manufacture.

Steps for creating Gerber-

1. First of all check your board properly for any errors or warning. Because once you have given the board for manufacturing than you cannot make changes so be careful.

2. Open your finish board. Then click on File and then on CAM Processor.

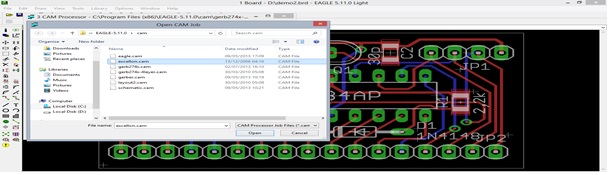

3. When you click on CAM Processor following window will appear.

4. Now click on File than open then job. Following window will appear.

5. When you select Job following widow will appear.

6. Now select Gerber274*.cam.

For a 2 layer board with silkscreen and solder mask on both sides so number of layer created will be seven and if you are designing 4 layer board then select gerber274*.4layer.cam. So take care for number of layers.

7. Now again go to File than Open than click on Job and select excellon.cam .Following window will appear.

8. Then click on Ok. Following window will appear.

9. Now click on Process job. This will generate drill data.

10. Now similarly click on File then Open then Job and select one by one all. Like eagle.com then Open than Process Job. Do similarly for gerber.cam, layout2.cam etc.

If you want to see the gerber data, open the file on word pad like I have opened the data of demo.cmp. Demo is the name of my file and .cmp indicates that it is the data of top layer. Your data will somewhat look like as shown (this is not the full data I have cut short it)-

Similarly you can also see another files data but it is not possible for us to read this data. And this data are fed to machine for manufacturing of PCB.

How to See Gerber Data

How you can see your gerber data

If you want to see your gerber file then you have to first download a software name gerber viewer and install it on your computer. It is freely available software. It is a good practise to check your layout before manufacturing because once it has been fabricated you cannot correct your mistake. Or it may happen that PCB will not be of any use this will lead to wastage of time and money both. So check it correctly. Once software is installed it will look like-

Now first of all find the location where you have saved all your file like I have saved it in D drive. You should always save all gerber file data on same location.

Then in the software select File than Open layer. Following window will appear and it will allow you to browse your location of gerber file.

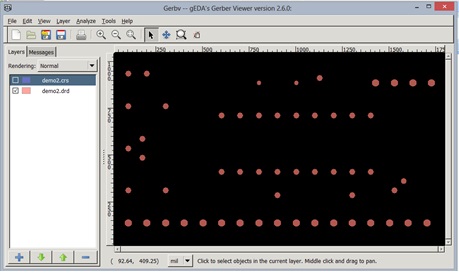

Then I have selected the file demo2.drd. Here demo is the same file which are use to generate gerber and .drd show the holes to be drilled so you can verify the same from your layout as shown in figure below.

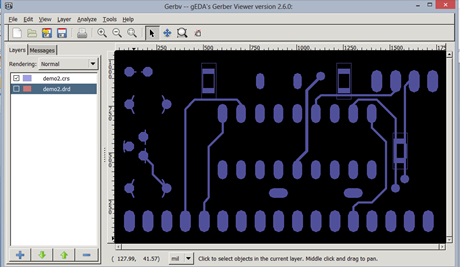

Similarly go to File then Open layer then select demo2.crs and you get pad also as shown in figure.

Similarly you can check different layers. Points to Remember

Project Source Code

Project Source Code

###

%!PS-Adobe-3.0 EPSF-3.0

%%Title: EAGLE Drawing D:/demo2.brd

%%Creator: EAGLE

%%Pages: 1

%%BoundingBox: 0 0 132 75

%%EndComments

% Coordinate transfer:

/EU { 254 div 0.072 mul } def

/inch { 72 mul } def

% Linestyle:

1 setlinecap

1 setlinejoin

% Drawing functions:

/l { % draw a line

/lw exch def

/y2 exch def

/x2 exch def

/y1 exch def

/x1 exch def

newpath

x1 EU y1 EU moveto

x2 EU y2 EU lineto

lw EU setlinewidth

stroke

} def

/h { % draw a hole

/d exch def

/y exch def

/x exch def

d 0 gt {

newpath

x EU y EU d 2 div EU 0 360 arc

currentgray dup

1 exch sub setgray

fill

setgray

} if

} def

/edge { 0.20710678119 mul } def

/o { % draw an octagon

/an exch def

/dy exch def

/dx exch def

/y exch def

/x exch def

gsave

x EU y EU translate

an dx dy lt { 90 add /dx dy /dy dx def def } if rotate

newpath

0 dx 2 div sub EU 0 dy edge add EU moveto

0 dx dy sub 2 div sub dy edge sub EU 0 dy 2 div add EU lineto

0 dx dy sub 2 div add dy edge add EU 0 dy 2 div add EU lineto

0 dx 2 div add EU 0 dy edge add EU lineto

0 dx 2 div add EU 0 dy edge sub EU lineto

0 dx dy sub 2 div add dy edge add EU 0 dy 2 div sub EU lineto

0 dx dy sub 2 div sub dy edge sub EU 0 dy 2 div sub EU lineto

0 dx 2 div sub EU 0 dy edge sub EU lineto

closepath

fill

grestore

} def

2724 2660 462974 2660 0 l

462974 2660 462974 262910 0 l

462974 262910 2724 262910 0 l

2724 262910 2724 2660 0 l

255074 230448 255074 219272 11176 l

204274 230448 204274 219272 11176 l

26474 78810 13208 13208 180.0 o

77274 78810 13208 p

26474 193110 13208 13208 180.0 o

77274 193110 13208 p

223070 72460 236278 72460 13208 l

324670 72460 337878 72460 13208 l

153474 97606 153474 110814 13208 l

178874 97606 178874 110814 13208 l

204274 97606 204274 110814 13208 l

229674 97606 229674 110814 13208 l

255074 97606 255074 110814 13208 l

###

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.