In the previous tutorial, open loop boost converter SMPS was designed. In this series, following SMPS circuits are designed –

1. Boost Converters –

a) Open Loop Boost Converter

b) Closed Loop Boost Converter

c) Open Loop Boost Converter with Adjustable Output

d) Closed Loop Boost Converter with Adjustable Output

2. Buck Converters –

a) Open Loop Buck Converter

b) Closed Loop Buck Converter

c) Open Loop Buck Converter with Adjustable Output

d) Closed Loop Buck Converter with Adjustable Output

3. Buck-Boost Converters

a) Open Loop Inverting Buck – Boost Converter

b) Open Loop Inverting Buck – Boost Converter with Adjustable Output

4. Flyback Converter

5. Push-Pull Converter

The open loop boost converter designed in the previous tutorial did not have constant and regulated voltage at the output. For a stable output, a Boost converter with error detection circuit needs to be designed. The error detection can be done by adding a feedback circuit which continuously checks the error in the output voltage and provides a regulated voltage at the output.

Therefore in this tutorial, a closed loop non–isolated boost converter is designed. The boost converter can be designed in two ways-

Open loop boost converter – In open loop boost converter, there is no feedback from output to input contrary to the closed loop which has a feedback circuit. So, the output of an open loop boost converter is not regulated.

Closed loop boost converter – In closed loop boost converter, there is a feedback from the output to the input. So, the output of a closed loop boost converter is regulated.

There are certain design parameters involved in the designing of the boost converter. It is important to understand these design parameters. Any boost converter can operate in either of the two possible modes of operation. These modes of operation are as follow –

• Continuous Conduction Mode (CCM)- In CCM, the current in the inductor is continuous in the entire cycle of the switching period. So a regulated voltage at the output is obtained but the output is regulated only if the current is drawn within the limits of CCM.

• Discontinuous Conduction Mode (DCM)- In this mode, the current in the inductor is pulsating and it becomes zero for a part of switching time. So a regulated voltage is not received in DCM. But, the voltage can be regulated by connecting a feedback circuit from output to input.

In this tutorial, a non-isolated boost converter is designed which means the input and output share the same ground. The boost converter designed in this project will step up 12V DC to 24V DC with a tolerance limit of +/-0.5V. Once the circuit is designed and assembled, the value of the output voltage and current will be observed using a multimeter. These values will indicate the efficiency of the boost converter designed in the project.

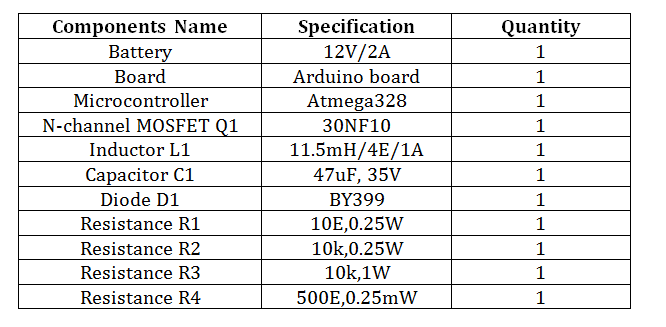

Components Required –

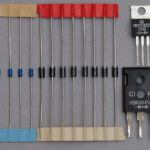

Fig. 1: List of Components required for Closed Loop Boost Converter

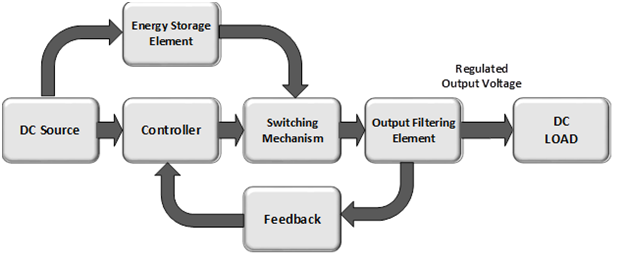

Block Diagram –

Fig. 2: Block Diagram of Closed Loop Boost Converter

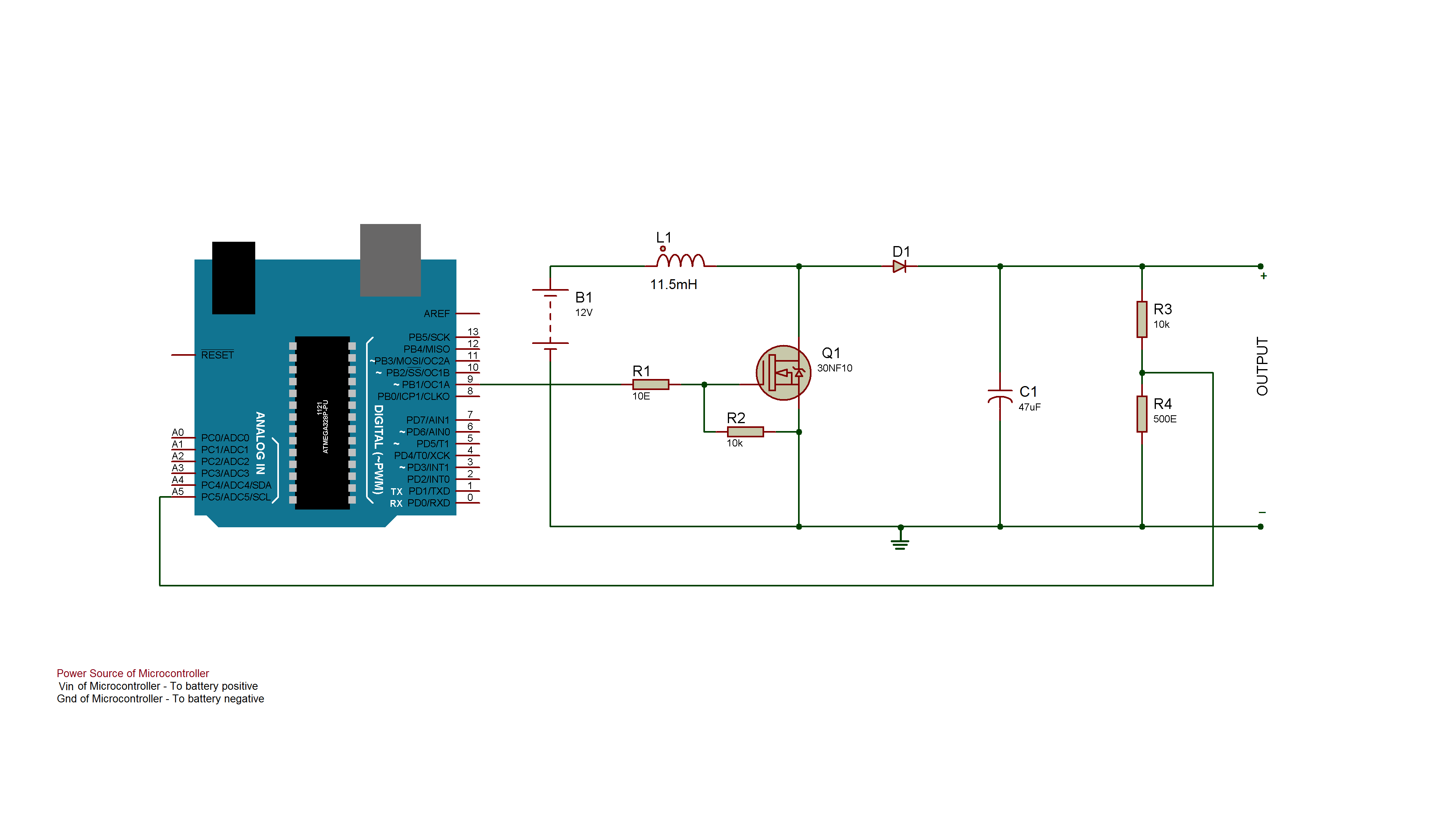

Circuit Connections –

In this experiment, a closed loop boost converter operating in DCM mode is designed and the component values as per the DCM standard equations are calculated for the desired output.

The boost converter designed in this tutorial will have the following design parameters –

Input voltage, Vin–A Lead-acid battery of 12V will be used as the source. The battery voltage will be the input voltage

Output voltage, Vout – The voltage desired at the output is 24V.

Maximum output current, Iout (max)–The maximum limit of output current will be 100 mA.

Output ripple voltage (dV) – The maximum output voltage ripple assumed at the output will be 100mV

Load resistance – In this circuit, a resistance at the output will be connected which will act like a load for the circuit. The maximum value of resistance can be calculated by Ohm’s law which is as follows –

Vout = Iout(max)*RL(max)

RL(max) = Vout/Iout(max)

By putting all the values,

RL = 240E

Now the power rating of the resistance can be calculated as follow – P = (Vout)2/(RL(max))

By putting all the values,

Pout = 2.4W

So, a resistance having 240E value and power rating equivalent or greater than the 2.4W will be used as the load at the output for maximum efficiency.

Frequency (Fs)– The frequency of the PWM signal generated by the micro controller should not be too high or low so a frequency of 10 KHz is selected to operate the switching components of the circuit. The value of the frequency is assumed.

The boost converter has the following circuit blocks –

1. DC source –

A 12V Battery is used as the input power source in the circuit. In the project, a lead acid battery of 12V is used. The battery voltage itself is the input voltage in the circuit.

2. Controller and switching mechanism –

An Oscillator is used to generate a Pulse Width Modulated (PWM) signal of the desired frequency. In this boost converter, Arduino UNO is used to generate the PWM signal so, the Arduino board is acting like an oscillator. The PWM signal is a train of the pulse which is used to turn ON and OFF the MOSFET. The MOSFET is used as the switching transistor in the circuit.

For switching purpose, a transistor and a diode are used as a switching component. For the selection of the transistor, MOSFET is chosen as FETs are known for their fast switching speed and low RDS (ON) (drain to source resistance in ON state). So an N-channel P30NF10 MOSFET (shown as Q1 in the circuit diagram) is connected parallel to the input DC source which acts like a switch in the circuit as its threshold voltage is very low, around 4V. So it can be triggered by a 5V PWM signal from the microcontroller. In ON state the Vds of P30NF10 MOSFET is also very low which reduces the power dissipation of our circuit.

For turning ON and OFF the MOSFET a train of the pulse should be applied to its gate. For this, the controller board generates a Pulse Width Modulated signal of 10kHz. This PWM signal is used to turn ON and OFF the MOSFET. For generating the PWM signal from the controller, an Arduino sketch has been burnt to the board. This Arduino sketch can be downloaded from the code section.

It should be noted that the switching time of the MOSFET and diode should be less than the rise and fall time of the PWM wave. A gate to source resistance must be used to avoid any unwanted triggering of the MOSFET by external noise. It also helps in fast turning OFF the MOSFET by discharging its parasitic capacitance. A low value of the resistor (10E to 500E) should be connected at the gate of the MOSFET. This will solve the problem of ringing (parasitic oscillations) and in rush current in the MOSFET. The voltage level of the PWM signal should be greater than the threshold voltage of the MOSFET. So that the MOSFET can be turned ON fully with minimum RDS (ON ).

Another switching component used in the circuit is a diode. The switching time of the diode should be less than the rise and fall time of the PWM wave. The Arduino board generates a PWM wave having rise time 110ns and fall time of 90ns. The forward voltage drop of the diode should also be very low otherwise it will dissipate power which will further reduce the efficiency of the circuit. The diode should offer low voltage drop in forward bias and the RDS (ON)of the MOSFET should be low. So in this experiment, a BY399 diode is selected which suits best to the circuit design.

Before generating the PWM signal the switching frequency for the circuit needs to be decided. For this boost converter, a switching frequency of 10kHz is selected which will work fine this converter design.

The duty cycle of the generated PWM signal is another important consideration as it will decide the active state of the MOSFET. The duty cycle can be calculated as follows –

D% = 1- (Vin/Vo)*100

Vo=Desired output voltage, 24V

Vin =Input voltage, 12V

By putting all the values in the above equation, the desired duty cycle is –

D = 50%

A capacitor and resistor of the appropriate value should be used for generating the 10 kHz frequency and 50% duty cycle. The higher is the frequency selected for switching components, the higher are the switching losses. This decreases the efficiency of the SMPS. But high switching frequency reduces the size of the energy storage element and improves the transient response of the output.

3. Energy Storage Element –

An inductor is used for storing the electrical energy in the form of magnetic field. So the inductor acts like an Energy Storage Element. An inductor of 11.5mH value is used in the circuit. For an inductor, a transformer’s secondary or primary coil, relay coil or any standard inductor can be used which has the desired inductance value.

4. Output Filtering Element –

As a filtering element, a capacitor (shown as C1 in the circuit diagram) is used at the output of the circuit. In normal operation of Boost circuit, the transistor Q1 turns ON and OFF according to the frequency of the oscillator circuit. This generates a train of the pulse at the inductor L1 and capacitor C3 as well as transistor Q1. As the capacitor is connected with inductor only in the negative cycle of the PWM signal, this makes an LC filter which filters the train of the pulse to produce a smooth DC at the output. The value of the capacitor can be calculated by using following equation of DCM –

C1>= (Io(max) * (1- (2*L1*Fs/RL)1/2))/ (Fs*dV)

By putting all the values in the above equation,

C1 >= (0.1*(1-(2*0.0115*10,000/240) 1/2))/ (10,000*0.1)

C1 >= 3uF

As a capacitor can be greater than the calculated value, any capacitor with an equivalent value to 3uF or greater than 3uF can be taken.

As it is the minimum value of capacitor required, so in the circuit, a capacitor of standard value is used which can be easily available and hence a capacitor of 47uF is taken.

5. Feedback circuit –

In the previous tutorial, it was seen that without any feedback circuit a high voltage at the output was received when there was no load connected. When any load at the output was connected then the output voltage dropped below the desired output voltage. so there was a need to regulate the output voltage by connecting a feedback circuit.

So in this circuit, a feedback is provided from the output terminal to the input terminal which regulates the output voltage even when no load is present at the output. The Feedback circuit has to calculate the error in the voltage and then the microcontroller automatically adjust the output voltage as per the desired voltage. This adjustment of the error voltage is managed by the Arduino sketch running on the board.

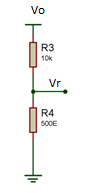

For providing feedback, a resistor ladder is used at the output(as shown in the circuit diagram). For calculating the value of resistor network, the maximum output voltage of the circuit in open loop must be known when no load is connected to the output. That will be the desired output voltage which should feed from the resistor divider network to the analog pin of the controller (as shown in circuit diagram). The output voltage should be equal to 5.2V as microcontroller provides the 5.2V as a reference voltage. The value of resistor network can be calculated as follow –

Fig. 3: Circuit Diagram of Resistive ladder used as feedback in closed loop boost converter

According to the resistor divider rule –

Vr= Vo*(R4/R3+R4)

Where,

Vr = desired output to the analog pin

Vo = output voltage of open loop boost converter without load.

It has been observed that the value of Vr and Vo are –

Vo = 110V

Vr = 5.2V

Let’s assume R3 = 10K now R4 is

5.2= 100*(R4/10K+R4)

R4 = 500E(approx.)

So R3 = 10K and R4 = 500E

Now the power rating of both the resistance R3 and R4 can be calculated as follows –

(For R3),P3 = (Vo-Vr)2/(R3)

By putting all the values,

P3 = 1W (approx.)

(For R4), P4 = (Vr)2/(R4)

By putting all the values,

P = 54mW (approx.)

How the circuit works –

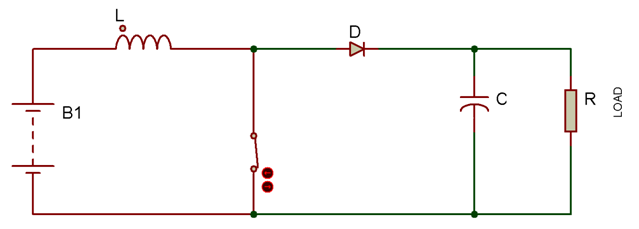

Any SMPS has some switching components which turn on and off at high frequency and has some storage component which stores the electrical energy while the switching components are in the conduction state and discharge the stored energy to the output device while the switching components are in the non-conduction state.

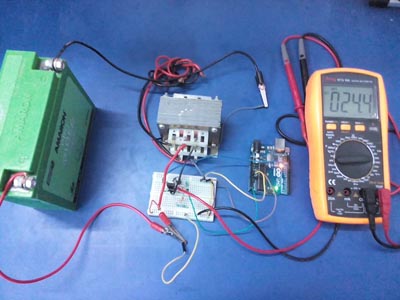

A simple Boost Converter consists of the inductor(L), a diode(D), a capacitor(C) and a transistor where transistor acts like a switch. In the boost circuit, when switch is closed i.e. the switching component is in conduction state, the inductor starts generating a magnetic field and stores energy. The stored energy in the inductor steps up the output voltage in comparison to the input voltage.

When current starts flowing through the switching component as its path is less resistive compared to the path in parallel which contains capacitor and the output load, the inductor generates a positive polarity at its left terminal and negative to right terminal. Due to change in polarity, the diode gets reverse biased. In this condition, the capacitor, which was charged in the previous cycle, provides the current to the load while the switching component goes in non-conduction state or goes open between the ground.

Fig. 4: Circuit Diagram showing ON state of switching Component in Boost Converter

When the switch is open the current is reduced as the impedance increases so the generated magnetic field in the inductor starts collapsing and the polarity of the inductor reverses. This makes the diode forward biased and the capacitor now starts charging with a voltage greater than the input voltage. As the input is now having two sources in series one is the inductor and another is the battery. So the output voltage is always greater than the input voltage.

Fig. 5: Circuit Diagram showing OFF state of switching Component in Boost Converter

So, in ON state, the Diode was in blocking Mode (OFF) and the Transistor was ON. In OFF state, the Diode was in conducting mode (ON) and the Transistor was OFF.

So, it can be said that the Boost Converter is having two switching components – one is the transistor and another one is the diode. At a time only one of the switching component conducts i.e. it is in ON state while the other goes in non-conduction state i.e. it goes in OFF state.

Testing the circuit –

The objective of making a closed loop boost converter is to increase the power efficiency of the circuit and improve the stability of the output.

In this circuit, Input Voltage, Vin = 12V

The output voltage when no load is connected is 24.3V

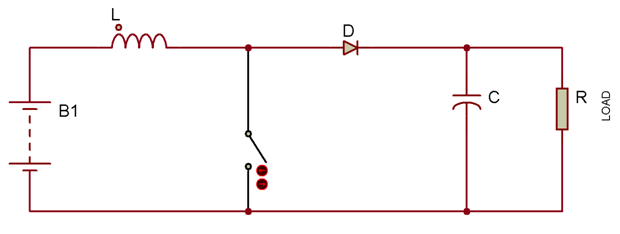

On measuring voltage and current values with different loads at the output, following observations were taken –

Fig. 6: Table listing output voltage and current from Closed Loop Boost Converter for different loads

So, it can be observed that a current of 100 mA can be drawn at 24.3V output with a tolerance limit of +/-0.5V.

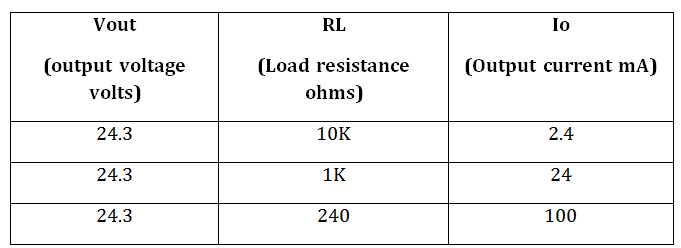

Fig. 7: Prototype of Closed Loop Boost Converter designed on a breadboard

The power efficiency of the circuit can be calculated as follows –

Efficiency % = (Pout/Pin)*100

(Output Power) Pout = Vout*Iout

(Output Voltage)Vout = 24.3V

(Output current) Iout = 100mA

Pout = 2430 mW(approx.)

(Input Power) Pin = Vin*Iin

(Input Voltage) Vin = 12V

(Input Current) Iin = 220mA (measured the input current using ammeter)

Pin = 2640mW

By putting all the values,

Efficiency % = 92%

It can be seen that on using a feedback circuit, the efficiency of the boost converter is increased from 88% (as calculated in the previous tutorial) to 92%.

This is a closed loop boost converter with non-isolated output and operating in DCM mode. It can be used as switching regulator for LED drivers and as a regulated DC power supply. It can be used for supplying power to low power portable electronic devices. In battery powered applications when there is a space restriction to stack the number of batteries in series for achieving high voltage, this boost converter can be used with less number of batteries to supply the DC power.

This boost converter is simple to design and use cheap components. It can be easily assembled in no time. Also, there is no need of control circuitry for PWM signal generation in this boost converter design.

You may also like:

Circuit Diagrams

Project Video

Filed Under: Tutorials

Filed Under: Tutorials

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.