An Electronic Energy Meter (EEM) functionally outperforms the traditional Ferrari’s wheel meter. One important advantage of EEM is that in non linear loads, its metering is highly accurate and electronic measurement is more robust than that of the conventional mechanical meters. The Power companies benefits from EEM in three significant ways.

1. It reduces the cost of theft and corruption on electricity distribution network with electronic designs and prepayment interfaces.

2. Electronic energy meter measures current in both Phase and Neutral lines and calculate power consumption based on the larger of the two currents.

3. EEM improves the cost and quality of electricity distribution.

Ferrari’s Wheel Meter and Electronic Meter

Fig. 1: Image of Ferrari’s Wheel Meter

Fig. 2: Image of Electronic Meter

How EEM Works?

The conventional mechanical energy meter is based on the phenomenon of “Magnetic Induction”. It has a rotating aluminium Wheel called Ferriwheel and many toothed wheels. Based on the flow of current, the Ferriwheel rotates which makes rotation of other wheels. This will be converted into corresponding measurements in the display section. Since many mechanical parts are involved, mechanical defects and breakdown are common. More over chances of manipulation and current theft will be higher.

Electronic Energy Meter is based on Digital Micro Technology (DMT) and uses no moving parts. So the EEM is known as “Static Energy Meter” In EEM the accurate functioning is controlled by a specially designed IC called ASIC (Application Specified Integrated Circuit). ASIC is constructed only for specific applications using Embedded System Technology. Similar ASIC are now used in Washing Machines, Air Conditioners, Automobiles, Digital Camera etc.

In addition to ASIC, analogue circuits, Voltage transformer, Current transformer etc are also present in EEM to “Sample” current and voltage. The ‘Input Data’ (Voltage) is compared with a programmed “Reference Data’ (Voltage) and finally a ‘Voltage Rate’ will be given to the output. This output is then converted into ‘Digital Data’ by the AD Converters (Analogue- Digital converter) present in the ASIC.

The Digital Data is then converted into an “Average Value”. Average Value / Mean Value is the measuring unit of power. The output of ASIC is available as “Pulses” indicated by the LED (Light Emitting Diode) placed on the front panel of EEM. These pulses are equal to Average Kilo Watt Hour (kWh / unit). Different ASIC with various kWh are used in different makes of EEMs. But usually 800 to 3600 pulses / kWh generating ASIC s are used in EEMs.The output of ASIC is sufficient to drive a Stepper Motor to give display through the rotation of digits embossed wheels. The output pulses are indicated through LED. The ASIC are manufactured by Analogue Device Company. ADE 7757 IC is generally used in many countries to make EEMs. ADE 7555 / 7755 ASIC maintains the international standard CLASS I IEC 687/ 1036.

Fig. 3: Inside Image of the Electronic Meter

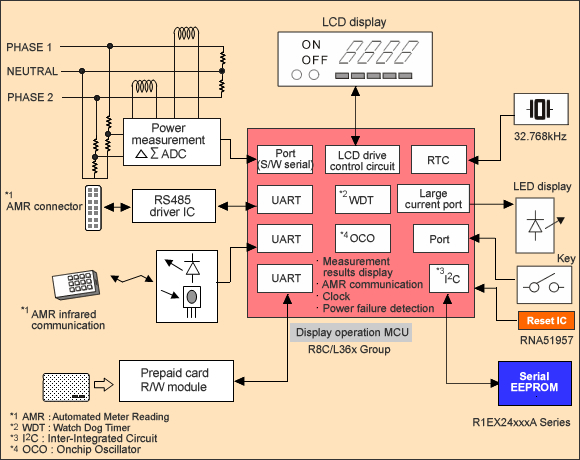

Block diagram of Electronic Meter

Fig. 4: Block diagram of Electronic Meter

On the front panel of EEM there will be 4 LED indications

N OK LED ON Phase and Neutral OK

E / L LED OFF Earthing correct

LED ON Earth leakage and current loss

Imp / kWh LED Blinks Impulses per Kilo Watt Hour.

This LED is larger one.

How to monitor EEM

How to Monitor the Electronic Energy Meter?

1. The first step to monitor the energy meter is counting of the LED pulses per unit (kWh). Usually the pulse rate will be 800 to 3600 imp/ kWh. Imp.3200 is the pulse rate of most EEMs. The pulse rate can be calculated by counting the blinking of LED.

2. Suppose the pulse rate is “X imp. / KWh”. (In most meters it is 3200 imp. / KWh). This indicates the pulse rate of LED if 1000 Watts / second is consumed in 1 hour.

3. Suppose a 100 watt bulb is switched on for 1 minute, the pulse rate will be “P”.

4. Then “P” can be calculated using the formula

P= X x100x60 / 1000×3600

That is if 1000 watts is consumed for 3600 seconds the output pulse will be “X” per hour. So the pulse rate for 100 watts for 60 seconds is “P”.

So “P” (100 watt per minute) can be calculated as follows:-

P= X x 100 x 60 / 1000 x 3600

That is 3200(X) x 100 x 60 / 1000 x 3600 = 5.3 pulses / minute

Normally if a 100 watts bulb burns for 1 minute, the pulse rate of LED will be 5.3 blinks per minute. + or – 5 times can be considered as normal. If the blinking rate is very high, your EEM is showing a wrong reading and you are forced to pay more.

Get ready to check your EEM

1. Connect a 100 watt bulb in an outlet holder.

2. Switch off all the lights, fans and unplug all the electric appliances.

3. Check the meter. If the LED blinks, it indicates wiring defects and leakage.

4. Check the wiring and rectify the defect.

5. If the LED remains OFF, wiring is OK and meter is not sensing the current flow.

6. Switch on the 100 W bulb with the help of another person and count the LED blinks for 1 minute. + or – 5 times can be ignored.

7. Take the total count per minute. It is the pulse rate for a 100 watt bulb/ minute( “P”)

8. If “P” is very high or low (for a 3200 kWh meter) than the “P” already calculated as above, the meter is defective.

9. Report the matter to the Power company for meter observation.

Know your home appliances; they are current hungry.

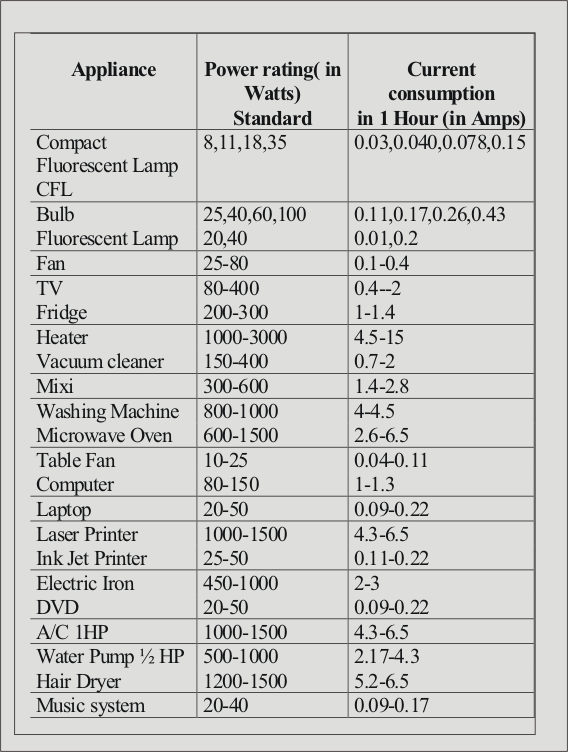

Most of the electric appliances consume large amount of current. If these instruments are kept ON for many hours, your electricity bill will be really shocking. The following chart will show you the power consumption of household electric appliances in One Hour.

Power rating of household appliances

Fig. 5: Image Showing Power rating of household appliances

The ratings are average. This may change depending on the make

Domestic power supply is 230 volts 50 kHz or 110V 60 Hz in some country. The current consumption depends on the Wattage of the instrument used. Current consumption can be calculated using the formula

I = W /V

I is the current in amperes, W is the wattage of instrument and V the 230 volt power supply.

For example a Compact Fluorescent Lamp (CFL) rated 11 watts consumes 0.04 ampere current in one hour at 230 volts.

Wattage of an instrument can be calculated using the formula

W= V x I

Tips to save energy

Some tips to make your appliances friendly and to save energy.

1. Check the domestic wiring periodically for leakage and current loss.

2. Install ELCB (Earth Leakage Circuit Breaker) which will immediately disconnect the power when it senses more than 40 milli ampere current through earth line.

3. Fridge is one of the current hungry appliances. Do not keep the door opened for more than 2 minutes. Do not keep hot food materials inside the fridge. Defrost weekly; otherwise current consumption will be more.

4. Do not keep TV or Computer in the standby mode for long periods. Switch off immediately after the use. Even in the standby mode these devices takes 10 watts or more power

5. Unplug all the instruments which are not using daily.

6. Make all the preparations before switching on the instruments like Washing machine, Mixi, Iron etc.

7. Use heater or water heater only in extreme cold conditions.

8. Restrict the use of Iron and use one with temperature regulator.

9. Overheating and humming from fans indicate defects which lead to over meter readings.

10. Switch off fans and lights after the use.

11. Do not charge UPS, Inverter or Emergency lamp battery continuously (If there is no cut off facility). It will consume more current as well as reduce the life of battery. One hour charging at an interval of two days is sufficient to keep the battery in top condition. Over charging will heat up the battery and reduce its life along with unnecessary power loss.

12. Keep the plugs and sockets clean to avoid sparking and power loss.

13. Avoid the use of Mixi, Heater, Iron etc during the peak hours from 6 pm to 10 pm.

14. Replace all the bulbs with Fluorescent lamps and low watt CFL

15. Use low wattage CFL lamps or LED Lamps in rooms or places where bright light is not required.

16. Do not charge Mobile phone daily. Equal charging and discharging will keep the battery in top condition. Charge the mobile phone only when the charge indicator shows 50% charge. Over charging will reduce the life of battery.

Remember! Unlike mechanical meter, Electronic energy meter will sense very small amount of current. Even a glowing indicator lamp in the switch board will cost something.

Electricity billing

Electricity billing is based on the usage of current by the domestic appliances. If a 1000 watts bulb burns for one hour, 1 unit current is used. Current consumption is calculated using the formula

Total Watts x 1 hour / 1000

For example, the total wattage of all the electric appliances used is 500 watts, the power consumption in one hour will be

500 x 1 / 1000 = 0.5 units

If the consumption per hour is 0.5 units and the appliances are used 8 hours per day, then the power consumption will be 4 units per day and 120 units per month.

Filed Under: Circuit Design

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.