In old days when modes of transportation were not there, people used to walk to the places they wanted to reach. For transportation of goods, bullock carts, camels, horses, etc. were often used. All this was meeting the mobility requirements as the settlements were not too dispersed.

As human settlements dispersed more and more, urban modes of transportation evolved. Buses, automobiles, trains, etc. came up and they provided a lot of

Fig. 1: A Representational Image of an Escalator

convenience to the travellers.

With the rapid advancement in the development of tall building and public facilities, it became paramount to address the need to transportation of pedestrians and also of goods. With multi-storeyed buildings or large shopping complexes or airports, it is unreasonable to expect the user to travel across the buildings/ public facilities by means of walking alone, at least not in a timely manner. Towards this end, innovations sprung up facilitating movement of pedestrians as well as goods in large shopping malls, multi-storeyed residential buildings, airports and other public facilities.

Today, elevators are a commonplace necessity in all residential buildings/ public facilities allowing movement of passengers and goods. Along with these, escalators and moving walkways have also become an integral part of urban lives. These enabling devices are expected to be present in most of the public facilities. Wherever elevation change is needed, elevators/ escalators or both are employed and allow pedestrians to traverse, with ease, longer distances than they could possibly do without such enabling devices. Similarly, moving walkways are of importance in dispersed facilities like airports.

LIFTS Vs ESCALATORS Vs MOVING WALKWAYS

All the three are enabling technologies to facilitate movement of personnel and goods across large residential/ public facilities. Lifts and Escalators are vertical building transportation systems whereas moving walkways are horizontal transportation system.

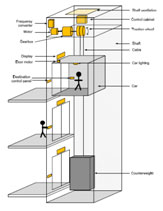

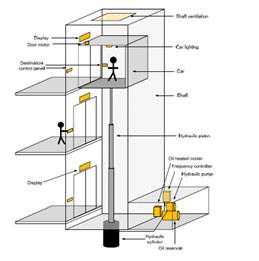

‘Lifts’, a prevalent terminology in UK, is referred to by ‘Elevators’ in US. An elevator is a hoisting or lowering mechanism, designed to carry passengers or freight, and is equipped with a car and platform that typically moves in fixed guides and serves two or more landings. Primarily they are of two types:electric traction type and hydraulic type.

· Traction elevators have an elevator car and counterweight attached to opposite ends of hoist ropes. The hoist ropes pass over a driving machine that raises and lowers the car. Traction elevators run on load-bearing rails in the elevator hoistway. Traction elevators are most often used in mid-rise and high-rise buildings with five or more floors.

Fig. 2: A Figure Representing Electronic Escalator

· On the other hand, hydraulic elevators are raised by forcing pressurized oil through a valve into a steel cylinder. The pressure forces a piston to rise, lifting the elevator platform and car enclosure mounted on it. The car is lowered by opening the valve and allowing the weight of the car to force oil from the cylinder in a controlled manner. When the valve is closed the car is stopped. Since the weight of hydraulic elevator cars is borne by the piston, there is no need for a structural framework or load-bearing rails. Hydraulic elevators are commonly found in low-rise buildings with two to five floors.

Fig. 3: A Figure Representing a Hydraulic Escalator

Different from lifts, escalators are moving staircases. Escalator can be described as moving stairs typically used to carry large number of people at high volumes through a limited no of floors. These are commonly used in high density areas or where sudden traffic surges are expected at times; for example at discharge times from offices, railways underground stations, airport terminals, theatres, shopping malls and departmental stores. In such applications, escalators will provide shorter travel time than elevators because elevator cars are limited in size and passengers have to wait longer for the service.

Fig. 4: A Representational Image of an Elevator

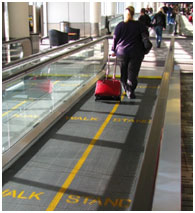

Moving walkways are also referred to by conveyors. They are horizontal, moving belt transportation systems enabling large number of people to travel through longer distances. They are suited for airports, high traffic areas like transit stations, etc.

Fig. 5: A Representational Image of a Moving Walkway

Advantages

ADVANTAGES- ESCALATORS

All these pedestrian transportation systems offer significant advantages to pedestrians

1. They help in reducing overall travel time across a facility.

2. Escalators and moving walkways, both being moving belt systems, help pedestrians to traverse longer distance by reducing the level of physical effort that must be expended.

3. Presence of Escalators and moving walkways improves the overall flow through an otherwise constricted area, thereby reducing the area required in the facility to accommodate a given number of people.

4. Since all passengers are transported through these at a constant rate, these systems also create a minimum speed at which all passengers must travel.

5. Conveyance of the moving belt system serves to increase throughput while at the same time decreases the speed differential through the constriction, therefore reducing conflicts.

6. Escalators occupy space no more than stairs.

An Inside Look

ESCALATORS-AN INSIDE LOOK

Escalators are power driven, inclined, continuous stairway used for raising or lowering the passengers. The word ‘Escalators’ is coined from two words, Elevator & Scala.

Fig. 6: An Equation of the Word Escalator Derived from Two Different Words

First patent on the concept of an escalator was granted to Nathan Ames in 1859. Later on, Leamon Souder obtained few patents on his designs of an escalator. However first actual working model of an escalator was developed by Jesse Reno in 1892 for an amusement park ride at Coney Island. In 1899, first commercial, step-type model was produced by Charles Seeberger, who actually used the term escalator for the first time. Later on, he sold the patents to Otis Elevator Company.

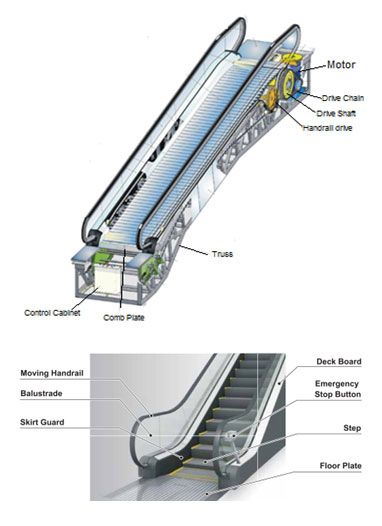

As mentioned earlier, escalators are load carrying units designed to transport people, between two landings. They are driven by an electric motor and a drive system that moves steps and handrails at synchronised speeds. The escalator is supported by a truss which contains all the mechanical components, such as the drive unit, brakes and chain.

Escalators typically travel at speeds of around 0.5 m/s – fast enough to provide rapid displacement and at the same time not disregarding comfort and safety.

Typical specifications of an escalator include the following

Power Supply requirements

Rated Speed: 0.5 and 0.65 m/s, up to 0.9-1.0 m/s on deep systems like subway

Transport Capacity: 4000-6000 passenger/hour.

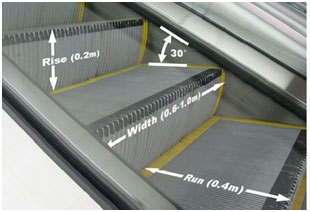

Inclination: usually at angle 30o; 35o if rise < 6 m & speed < 0.5 m/s

Step Width: 600, 800 & 1000 mm; min. step or tread length = 400 mm

Escalator Width

Width between moving handrails

Width between skirt guards

Truss Width

Boarding and alighting areas: Safe boarding, 1.33 – 2.33 flat steps

Environment: Indoor/Outdoor

Fig. 7: A Figure Illustrating Typical Specifications of an Escalator

The specifications are primarily governed by American Society of Mechanical Engineers’ Safety Code for Elevators and Escalators (Donoghue, 1981).

Escalators are used both in commercial buildings and in public transport facilities such as airports, subways and metro/railway stations.

Parts of Escalators

PARTS OF ESCALATORS

· Trusses

The escalator machinery is hidden beneath its steps in a structure called a truss. They are designed to accommodate the width of the escalator and are of ample strengths to maintain alignment of the tracks and moving parts, safely retain steps and running gear. It also retains step mechanism within guides and envelope of the truss, in case of failure of track systems.

· Gears and Motors

An electric motor is housed inside the truss at the top of the escalator. Motors typically used are AC induction motors. All escalators have four gears; two drive gears on present on either side at the top and two return gears are there on either side at the bottom. The electric motor runs these four gears. The gears are connected through stepchains that loop around them and run down on both sides of the escalator. The chains are connected to each step and therefore help the steps move up or down the escalator.

· Step Chains

They pull the steps to the top from the bottom platform in an endless loop.

· Steps

Steps are of horizontal tread formation; the step treads are of cleat type to assure secure foothold and comfortable tread surface. Visual demarcation is usually provided on the front and rear edges of each step to indicate the edges.

Each escalator step has four wheels below the step; two each on either side. The two wheels that are closest to the top of the step connect the steps to the two chains that loop around the gears. The horizontal positioning of that chain at the top and bottom causes the steps, in turn, to flatten out. The two wheels that are closest to the bottom of the step roll along a rail within the truss for stability. The grooves in the steps of escalators help with alignment.

· Tracks

Track system built into the truss; retain steps and running gear under extreme load requirements and at the highest speed of operation.

Relative position of Step-wheel track(front wheels of the steps) and trailer wheel track(back wheels of the steps) causes formation of staircase when the steps move out of comb plate and also, make the steps lay flat at top and bottom of the escalator.

· Controller

Controller is housed in NEMA enclosure. Controllers include a circuit breaker, local disconnect, motor starter, control relays, fault indicator, and all other functions of escalator controller. Motor starter limit the starting current of the motor and protect the motor against overload, input power phase reversals, etc. Controller also include an emergency stop to disconnect the power supply to the driving machine motor and apply brakes to stop the escalator at controlled speed.

Controllers include a fault indicating device in the front panel of the controller to visually indicate and identify actuation of safety devices causing escalator shutdown. Controllers have interfaces for fire alarms and seismic sensors. In case of any such event, emergency stop is activated.

Also, they are interfaced with SCADA for remote system monitoring.

· Handrails & Handrail Drive Systems

The handrails are used by travellers for balance and safety.

The handrail is essentially a long rubber loop, a moving handhold provided for escalator passengers, which moves over the top of the balustrade and newels. Handrails receive their motion from the same system that powers the steps, i.e., the main escalator drive through direct gearing and drive shaft or drive chains so that the handrails and steps operate at the same speed in each direction of travel.

A handrail guard is also fitted over the outside of the handrail at a point where the handrail enters or leaves the balustrade. It is designed to keep a person’s fingers out of the handrail opening.

· Balustrade

Balustrades are the sides of an escalator extending above the steps. It includes skirt panels, interior panels, skirt Panels, decks and handrails.

. Drip Pans

Drip pans are provided for the escalators to collect oil, grease from step linkages, rain water and loose debris that may get deposited into escalator truss. Drip pans are sloped so that liquids collected drain toward the lower section of the truss and finally routed to the industrial drain.

· Safety Devices

Safety devices, depending upon the interruption of electric circuit for the operation, are interlocked to isolate electric power supply to the motor and apply brakes to stop the escalator smoothly and safely in a direction of travel. It also prevents operation of escalator until safety hazard/ malfunction has been corrected.

Various types of safety devices are used in escalators – Emergency Stop Button, Overload Detection Device, Speed Governor, Broken Drive Chain Device, Handrail speed monitoring device, Skirt Obstruction Device, Missing Step Device, Broken Chain Step Device, etc.

· Brakes

Brakes stop the escalator upon activation of normal control, emergency stop buttons, upon activation of safety devices or upon loss of power.

. Overspeed governor

Overspeed governor cuts off the power supply to the motor and bring the escalator to rest when the speed varies more than the specified percentage of the rated speed.

· Landing Plates(Top & Bottom Floor Plates)

The landing platform houses the curved portions of the tracks, gears & motors. The floor plate is the entry point for moving onto escalator steps. In between steps and floor plate, a comb plate is used; the comb plates have cleats matching with cleats of the steps.

Landing plates are designed to be supported on the truss head and cover the entire area of landing within the outline of the truss.

The parts are shown in the two pictures below:

Fig. 8: A Diagram Illustrating Various Parts of an Escalator

Design Factors

IMPORTANT DESIGN FACTORS

Several factors go into the planning and design of escalator systems. The following is the list of major factors

1. Traffic Analysis

Escalators’ planning is highly dependent on the ‘traffic analysis’ study. Traffic analysis is the study of the population distribution and their predicted pattern of flow within a day.

Efficiency of an escalator system is defined in terms of the quality of service (passenger handling capacity) and quality of service (passenger waiting time).

Traffic Analysis helps to determine the speed of the escalator system, and also the number of system required to achiever good quality of service.

2. Passenger handling capacity

Passenger handling capacity is the number of passengers that the system can transport within a specified duration, with average specified loading of the escalator (typically 80% of rated value).

Handling capacity of the escalator is calculated as

Fig. 9: An Equation Representing the Calculation of Handling Capacity of an Escalator

Where, N: No. of persons moved per hour

P: No. of persons per step

V: Escalator Speed (m/s)

L: Length of step (m)

q: Inclination angle (°)

3. Capacity

Capacity is the rated load for which escalator is designed. It should be higher than the maximum load during peak traffic conditions.

4. Speed of the escalator

Speed of the escalator should be sufficient to avoid long queues of passengers, during peak traffic conditions.

Along with these, safe operation, comfort to travellers, minimum space requirements, less installation and operating costs, aesthetics and regulatory norms are some other very important parameters considered during the design of Escalators. In addition, location of the escalator should also be given due importance during planning of escalator system for an area. Escalators can be arranged in variety of fashions, viz., Parallel, Multiple parallel, Cross Over or Criss-Cross or Walkaround

COMMERCIALLY AVAILABLE PRODUCTS

Full Escalator system is being manufactured by number of companies. Some of the popular ones are listed below:

1. Otis Elevator Company

2. Mitsubishi Electric

3. Kone

4. Schindler

5. Kleemann

Filed Under: Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.