Few have named the CubeSats or ‘Nano-satellites’ of NASA because of their comparatively small dimensions that are grounded on the size of a Beanie Baby box, one of their founders available in a store. The size of CubeSats is small, weighing approximately only 1 to 10 kilograms, but they are not small to the nanoscale.

It is true that the CubeSats are not going to shrink down to the nanoscale at any time soon, but they contain at least a little bit of nanotechnology. For the very first time, scientists at the NASA’s Goddard Space Flight Centre have utilized carbon based nanotubes in an epoxy resin to engineer a mirror for a minute weight telescope on a CubeSat.

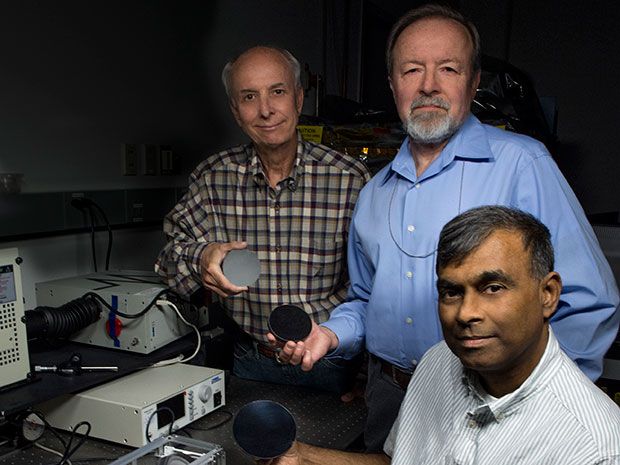

“Till date, no one has been able to craft a mirror by utilizing a carbon nanotube resin,” says Peter Chen, a contractor at Goddard and president of Tiny Weight Telescopes, Inc., that is performing with the team for creating the CubeSat – compatible telescope.

“It is a different technology that is presently available only at the Goddard,” he continues. “The technology is very much novel to be identified in the space and first, must go through the distinct levels of improvement in technologies.”

If the nanotube made with carbon allowed telescope does to create it space, it will be a component of an optical system containing three commercially accessible, miniaturized spectrometers optimized for the visible, near-infrared ultraviolet wavelengths bands

In the prototype the scientists have fashioned, the spectrometers are linked through fiber optic cables to the dedicated beam of a three-inch diameter carbon-nanotube mirror.

The utilization of a carbon nanotube mirror in a CubeSat telescope provides innumerable benefits over conventional materials, such as aluminium or glass. Or crucial significance is the less weight characteristic of the carbon nanotube epoxy resin. But, the scientists also ensure that the material is extremely stable, conveniently reproducible, and it does not need polishing, which is an expensive and time-consuming process.

For preparing the carbon-nanotube mirrors, a blend of carbon nanotubes and epoxy are filtered into a mold that has been created to impart few optical properties. The set framework is then heated to cure and strengthen the epoxy. After the epoxy has strengthened, the mirror is then layered with a reflective substance of silicon dioxide and aluminium.

“After creating a particular mold or mandrel, numerous tens of similar low-mass, greatly uniform replicas can be generated at reduced prices,” says Chen. “Overall telescope assemblies can be prepared this way, which is of core interest for the team. For the program of CubeSat, this potential will allow numerous spacecraft to be incorporated with similar optics and distinct detectors for an array of experiments. Also, they can be flown in constellations and swarms.”

While the main aim is that this mirror will be utilized in the tiny confines of a CubeSat, it is believed among the scientists that it could also be employed in extensively scaled telescopes, like the James Webb Space Telescope which holds 6.4 metre primary mirror. In addition to this, the carbon based nanotube resin can also be exposed to an electronic field before curing that will make carbon nanotube networks and chains.

Filed Under: News

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.