Juan Hinestroza recently took a step ahead towards cleaner manufacturing. An associate professor at the College of Human Ecology, he has been travelling to a number of manufacturing facilities all over the world. He claims that there are a few area on this planet where he can recognize the color of fashion by just taking a peek at the nearby river. In his own words, “I saw it with my own eyes, it’s very sad.”

There are so many manufacturing plants all over the world that cast away their waste products from textile dying and several other processes into waterways and air directly. These people make no efforts to reduce or mitigate effects of these waste materials over environment. He further adds,”There are companies that make a great effort to make things in a clean and responsible manner, but there are other that don’t.”

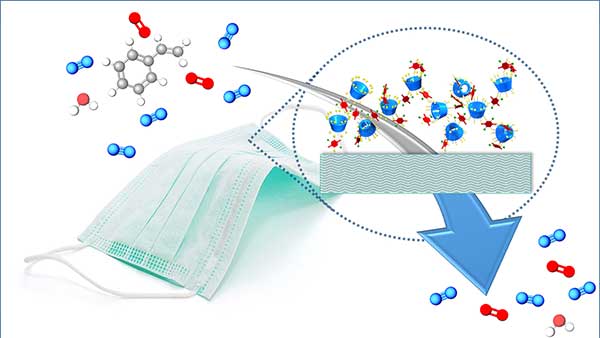

He hopes that a technology that was recently developed at the Cornell in association with previous Cornell chemistry faculty, Professor Will Dichtel, will help the industries in cleaning up their acts. The team has showcased the power to infuse cotton with a beta-cyclodextrin (BCD) polymer that works as a filtration device that has equal effect on air and water. The first author of this paper, Diego Alzate-Sanchez as well as Dichtel are now working at the Northwestern University. The other contributors include a previous postdoctoral researcher, Brian J. Smith along with Alaaeddin Alsbaiee.

The cotton fabric was initially functionalized when it participated in the polymerization process. Addition of this material in the reaction resulted in an unmatched polymer that grafted over the cotton surface. Hinestroza adds, “One of the limitations of some super-absorbents is that you need to be able to put them into a substrate that can be easily manufactured. Fibers are perfect for that – fibers are everywhere.” A scanning electron microscopy recently showcased that the cotton fibers that participated in the reaction remained unaltered post the polymerization reaction. When these were tested for absorption of air and water pollutants, these absorbed larger amount of pollutants as compared to the raw untreated cotton fabric strands. Hinestroza also pointed out that there were several other positive points that made this functionalized fabric technology attractive to the complete industry. He says, “We’re compatible with existing textile machinery – you wouldn’t have to do a lot of retooling. It works on both air and water, and we proved that we can remove the compounds and reuse the fiber over and over again.”

Filed Under: News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.