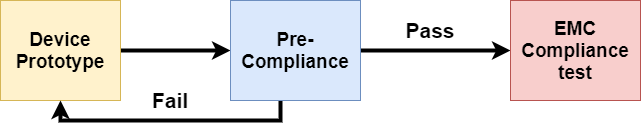

EMC testing is essential to get a certification of Electromagnetic Emission and Immunity test before launching the product in the market. However, actual EMC tests are pretty expensive. Before going for the actual EMC test, the product should test in EMC pre-compliance test Lab. Pre-compliance testing will mimic all tests performed at EMI/EMC test labs to ensure the device will pass the EMI/EMC compliance test. Compliance test labs are very costly and difficult to pass; the pre-compliance testing cost is cheaper than the actual cost of EMI/EMC compliance test labs and will give approximately the same result.

This article covers how to perform a pre-compliance test focusing on cheap or easy to set up tests to build confidence for actual EMI/EMC tests.

As discussed in previous articles, the EMI/EMC is an emission test to measure electromagnetic interference generated by the device. The EMI tests or Electromagnetic interference test Limits depend upon standards defined by the country’s regulations. This also depends upon the application of the product or device. For example, EMI/EMC test for medical products is rigorous because medical equipment needs to be accurate in any condition. If medical devices generate any emission, then it will affect other medical devices it causes a false reading.

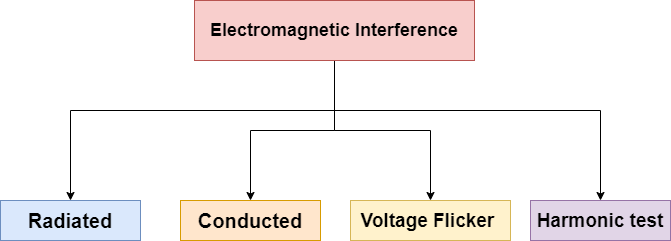

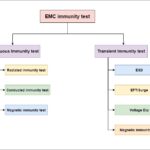

Types of EMI pre-compliance tests

The most common test which performs on almost every device is given in the block diagram. The reason for EMI test failure could be PCB design, shielding, components, antennas. These all lead to cause radiated and conducted emissions. That’s why most failures in the EMI test occur in Radiated and conducted emissions. Below some method is discussed to set up and measure radiated and conducted emission pre-compliance tests at the DIY lab.

Radiated emission test

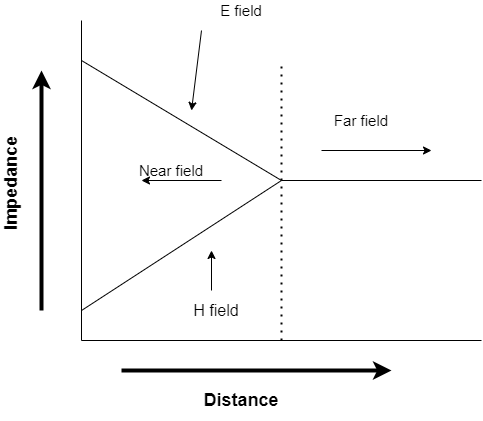

Two methods can measure the radiation emission: a far-field method and a near-field method. Before knowing how to measure radiated emission in these fields, let’s understand the difference between near-field and far-field measurements.

When oscillating electricity passes through a conductor, it induces a magnetic field. The induced magnetic field also creates an electrified field, as shown below. The H field represents the magnetic field, and the E field represents an electric field.

The device or equipment under test will produce both E field and H field. The electric field has a high impedance at the near of product, and the magnetic field has a low impedance called a near field. At a certain distance, the electric field and magnetic field combine at the same impedance, which is a far-field. The meeting distance of the E field and H field depends upon the frequency of waves.

Near-Field Radiated emission test

A measurement probe is used near the circuit to measure the E field waves and H field waves. This is the cheapest measurement technique designers use to get an idea of troubleshooting in EMI tests on their products. The near-field test is not as accurate as a far-field test, but it gives an idea of EMI induced in the product during the pre-compliance test.

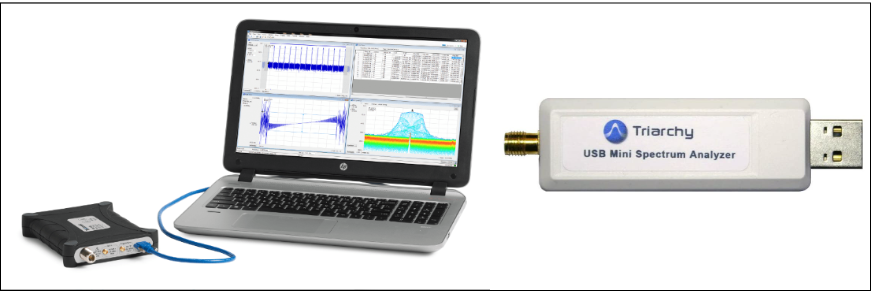

You will need a spectrum analyzer and measurement probes to measure near-field tests. There are some expensive spectrum analyzers available in the market, but a “pocket RF explorer” or USB spectrum analyzer dongle can work in some cases.

There are various types of near-field probes available in the market, or you can make your own. The image below is of electric field probes; there are two probes, one probe has a pointed tip, and another one has a round tip. The rounded tip covers a wider area to measure the electric field in a circuit. Once the area is found where the electric field is generated, the small pointed tip probe will find the specific area of the electric field. These probes are not sensitive to orientation so that measurements can be taken in any direction.

The magnetic field probes have a loop to measure the magnetic field. There are two probes in the image below: one has a small diameter ring, and the other has a large diameter ring. The large diameter ring measures the magnetic field in the wider area. After finding the magnetic field area, the smaller diameter probe can be used to find a specific area where electromagnetic fields are produced. These probes are very sensitive to orientation, so keep in mind that the readings will be taken at the same orientation, and the probe ring parallel to the circuit will give a much better result.

This setup needs an RF amplifier to amplify the signal coming from the probe to feed into the spectrum analyzer. The standard probes come with the amplifier, but you can buy an RF amplifier PCB online for DIY probs.

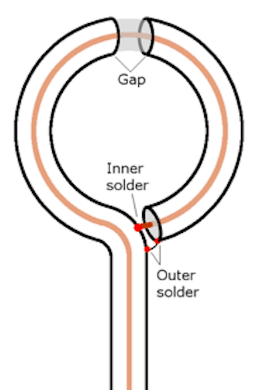

- DIY near H field probe

DIY probe can be made at a lower price than an actual probe in the market. Just buy a semi-rigid cable and follow the diagram given below. As in the diagram, make a loop of wire and solder its inner wire with an outer shield, and then solder it to make a loop as shown below.

After making this loop, cut the outer shield to create a gap between the loop, as shown in the image below.

Now dip it into an insulating paint or use some spray paint to get an insulating layer so this will not touch the open area in the circuit. Use a ferrite clamp to avoid external noise, as shown in the image.

Far-Field Radiated emission test

Near-field measurement can only provide an idea of troubleshooting, but it cannot accurately read the emission. That’s why EMI/EMC test labs use far-field radiated emission tests. This is expensive and a little hard to set up. So it is not easy to set it up in DIY pre-compliance labs, but some EMC pre-compliance labs provide this setup. The far-field test can be performed in two types of areas.

- Open area test site (OTAs)

- Semi Anechoic Chamber (SAC)

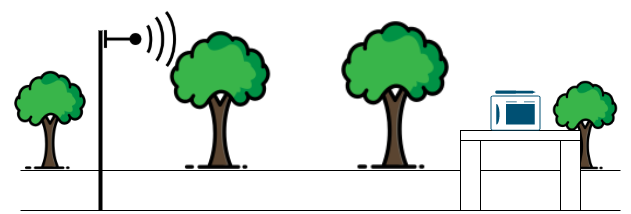

- Open Area Site (OTAs)

In the open area test, the setup is in an open area where minimal RF reflective objects are close to the area. The ground should be RF reflective and flat so the antenna can get measurements directly from EUT(equipment under test) and the reflection of the ground.

The minimum distance between EUT and the antenna should be 3 meters. If the distance is reduced to less than 3 meters, it will be considered near field measurement, which will be less accurate. To get accurate readings at 30Mhz, one wavelength is 10m, and at 100Mhz, one wavelength is 3m.

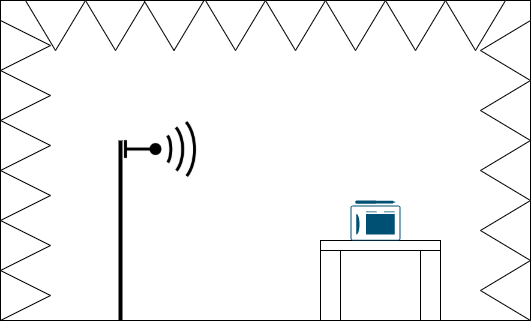

- Semi-Anechoic Chamber (SAC)

The semi-Anechoic chamber is made up of metal walls with RF absorbing material. RF Absorbing material absorbs RF signal produced by EUT. The size of the chamber depends upon which standard is applied to the product. The distance between antenna and EUT is generally 3m,5m, and 10m.

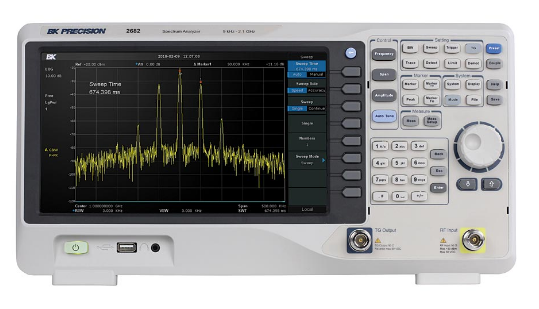

- Spectrum analyzer/EMI receiver

As discussed in the near field test, every Lab needs a spectrum analyzer to measure the RF signals accurately. Ensure the spectrum analyzer can cover all frequency ranges that need to be investigated for EUT (e.g., 30Mhz to 5Ghz). Most Spectrum analyzers can measure “peak”, “Average,” and “quasi-peak”, Which helps in measurement.

- Antenna

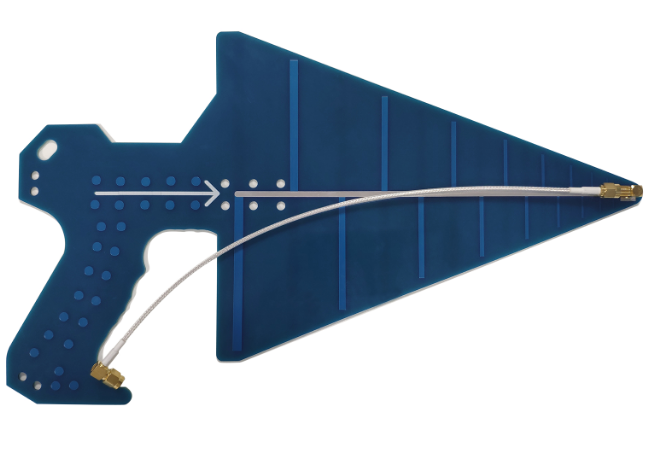

The antenna is the most important component of far-field measurement. The lower frequency measurement will increase the antenna size and cost, the Higher frequency measurement will reduce the antenna size and cost. The antenna must be calibrated to get the exact antenna factors needed for accurate field strength measurement. The maximum signal receives at a particular height so the antenna can move from 4 meters to 6 meters high to get the maximum EMI signal. the cheapest antenna will not able to measure low frequency. The image shown below is the PCB-based antenna to measure frequency from 0.6GHz to 10 GHz.

- Turnable table

In the far-field measurement either OATS or SAC need a turnable table because the emission from the EUT device is usually directional. The table should be made of wood or any material that does not impact the measurement. The turnable table should be rotated at 360 degrees of rotation so the measurement can be done in every direction of EUT.

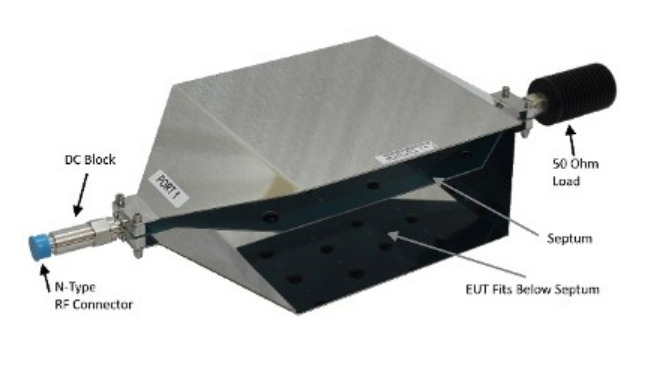

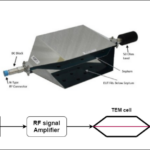

- TEM cell

This is another option to test the radiated emission test. The TEM cell stands for transverse Electromagnetic test. TEM cells consist of the septum, a conductive plan in the middle, connected with a 50 Ohm load. The smaller the TEM cell will catch, the higher frequency and the larger TEM cell will catch the lower frequency. It can be bought or made with proper dimensions according to frequency.

Conducted emission test

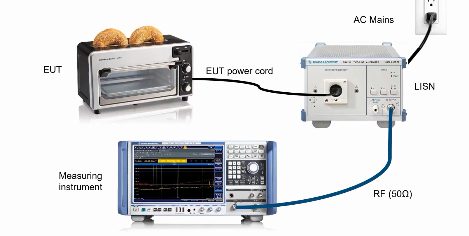

Conducted emission test is not complicated as Radiated emission pre-compliance test because the equipment and setup required for this test are much smaller. You need only a spectrum analyzer and LISN device for the emission pre-compliance test. Above already discussed radiated emission different Spectrum analyzer options. Now let’s understand what LISN devices do?

LISN stands for Line impedance stabilization network, this device is used for a Conducted emission test. The device will be connected between supply and EUT. It will help to measure the RF noise generated by EUT in supply. The RF noise measured by the LISN device can be measured using a spectrum analyzer.

EMI/EMC Limits

The EMI/ EMC limits depend upon the EMI regulatory standards of the country. In the U.S., the interference is regulated by FCC (Federal Communications Commission). The FCC categorizes the devices in Class A and Class B. A Class A device is for industrial use, and the device intended for residential use is under Class B. The table below shows the Limits according to FCC for Class A and Class B devices.

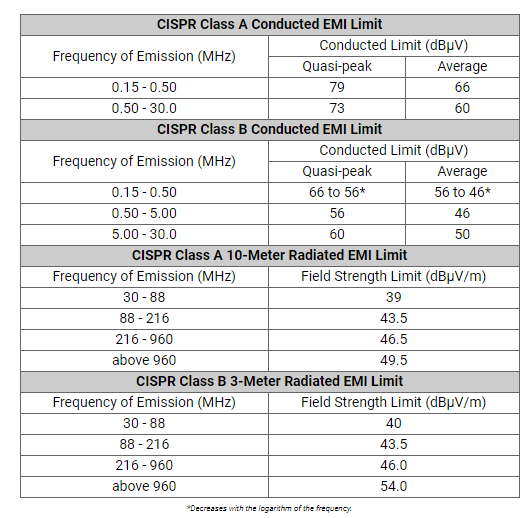

In Europe, the interference is regulated by CISPR. This is also categorized device in two categories. The categories are the same as FCC. Class A is for industrial devices, and Class B devices for residential. The limits for these devices according to CISPR are given below.

You may also like:

Filed Under: EMI/EMC/RFI, Tutorials