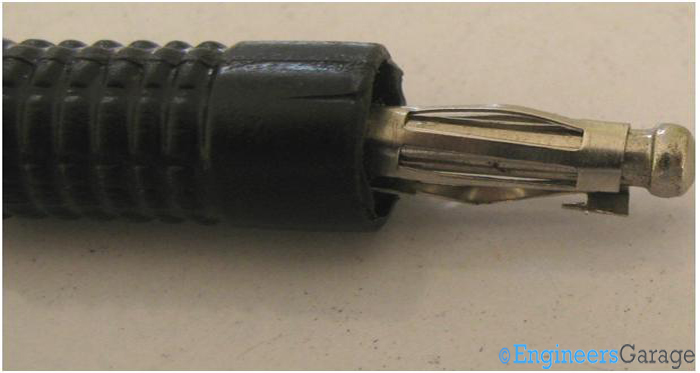

Fig. 1: Image of Banana Jack/Connector

Banana connectors are a popular species of electrical connectors which find major use in connecting power amplifiers, speakers, woofers etc. in audio systems. Designed for high power applications, these connectors are known to work at an average of 1000volts and 15amperes. In any audio set up, the connectors are color coded into red and black where red connector holds the live wire while the black one serves as a reference (ground). Except the color coding, there is no structural difference between the connectors.

This Insight will give you a sneak-peek inside the assembly of such a connector, along with its external and internal details.

Outer Structure

Fig. 2: Outer Structure and Mechanics of Banana Connector

Outer Structure: Image 02 pictures a conventional male banana connector. An assembly of metal contact and a plastic sleeve, the assembly is both durable and compact. The plastic sleeve is made from Nylon while the metal contacts are made from copper and plated with nickel.

Fig. 3: Spring Plug Mechanism of Connector

A plug spring structure is placed on the connector. This spring enables a good link with the female counterpart.

Male & Female Connectors

Fig. 4: (Left image) Input Port (Right image) Male Connector

Different Banana Connectors: Male and female connectors are shown in Image03 and Image04, respectively. The female appears to be a simple input port. When male connector is inserted, the plug springs get compressed the moment the connector is inserted. After the insertion is complete, the spring jumps back to its rest position and a tight link is established.

Fig. 5: Connector Linking Mechanism

Link between male and female connectors: Image 05 details with the manner in which the connectors mate. Even when kept in an oblique position, the link is as good as it is in the earlier position.

Engaging Force and Dissembled Connector

Fig. 6: Image Showing Strong Engaging Force of Connectors

Tight Connection: The force required to disengage the connectors is more when compared to the force required in engaging them. A connection like this is not only resistant to mechanical stresses but also maintains the signal quality for high power systems.

Fig. 7: Dissembled Parts of Connector showing Mechanism of Banana Jack Connector

Dissembled Connector: The assembly is uncomplicated and the metal contact can be easily plucked out of the plastic sleeve with hands. However, once opened, the contact pin region reveals a screw through which the wire connects. It also has rings through which it gets attached to the plastic part of the connector.

Connecting Screw

Fig. 8: Image of Connector Screw

Fig. 9: Image of Assembly of Connector Pin and Screw

Connecting Screw: The screw is small, its radius approximately [6mm] but it is able to cover the contact pin grove as can be seen in the images above.

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.