Bread Board is a great tool to design and test your circuits. You do not need to solder wires and components to make a circuit while using a bread board. It is easier to mount components & reuse them. Since, components are not soldered you can change your circuit design at any point without any hassle.

Structure of a Bread Board: Basically, a bread board is an array of conductive metal clips encased in a box made of white ABS plastic, where each clip is insulated with another clips. There are a number of holes on the plastic box, arranged in a particular fashion. A typical bread board layout consists of two types of region also called strips. Bus strips and socket strips. Bus strips are usually used to provide power supply to the circuit. It consists of two columns, one for power voltage and other for ground.

Socket strips are used to hold most of the components in a circuit. Generally it consists of two sections each with 5 rows and 64 columns. Every column is electrically connected from inside.

Fig. 1: Front View—Bread Board Encased in ABS Plastic Box

The above image shows the front view of a general purpose bread board.

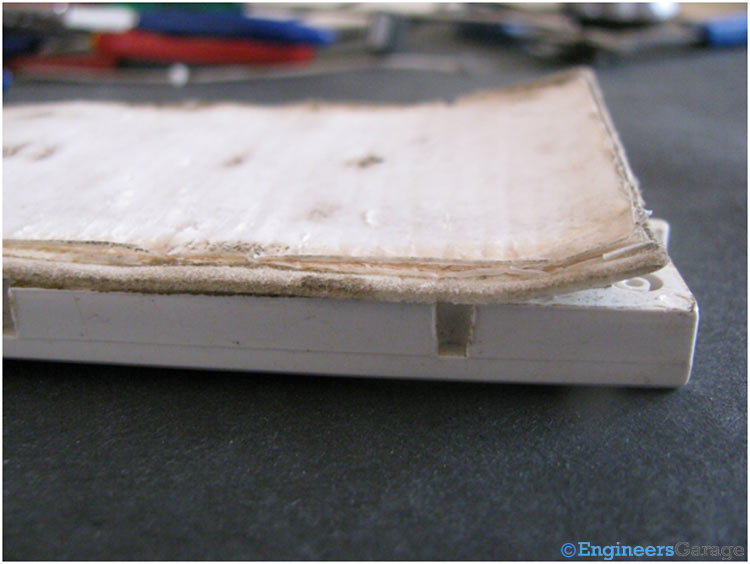

The back view looks something like this:

Fig. 2: Back View—Bread Board Covered With Thick Paper Attached With Glue

The back side area is covered with a thick paper covering which is attached to the casing with the help of glue.

Clips Arrangement

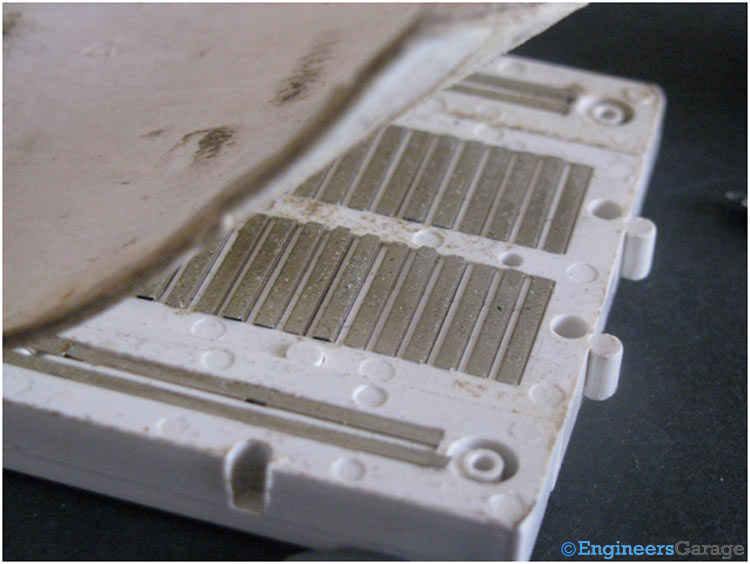

Removing the paper covering unveils the subsequent view:

Fig. 3: Back View—Bread Board With Thick Cover Removed Showing Metal Clips

In next image you can clearly view the internal structure of a bread board. The heart of a bread board is these metal clips. These metal clips are generally made of nickel silver as it is conductive, corrosion resistant and little stretchable too.

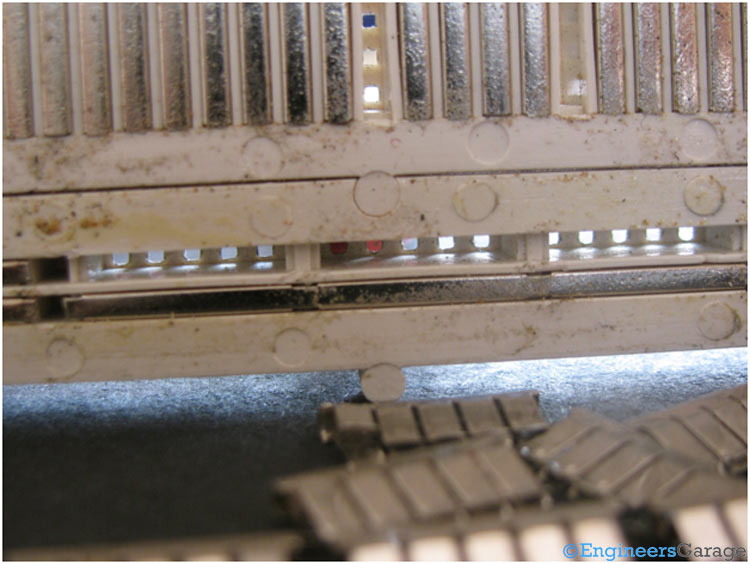

Fig. 4: Bread Board Internal Structure—Arrangement of Metal Clips

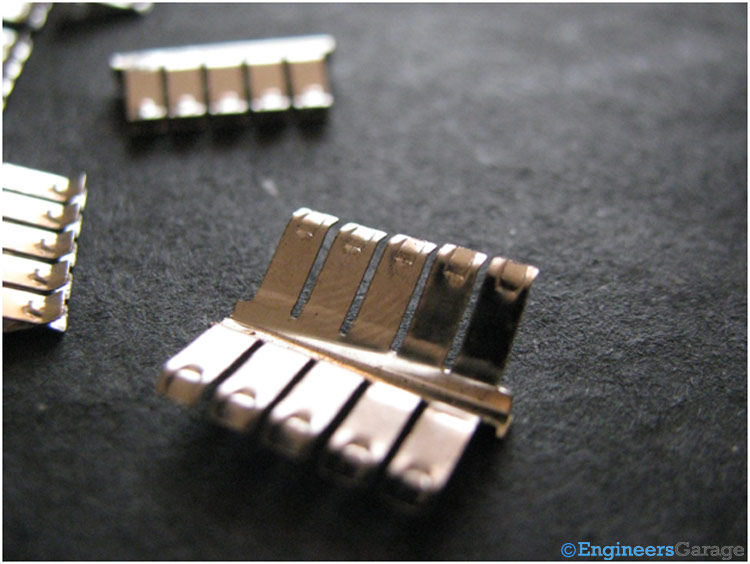

We can see there are two types of clips in the bread board, one for bus strip and other for socket strip. Let’s remove them from the plastic blocks to have a closure look.

Fig. 5: Types of Clips in Bread Board—One for Bus Strip, Other for Socket Strip

There are a total of 128 metal clips in socket strip region each with 5 holes and 8 clips in bus strip region each with 25 holes.

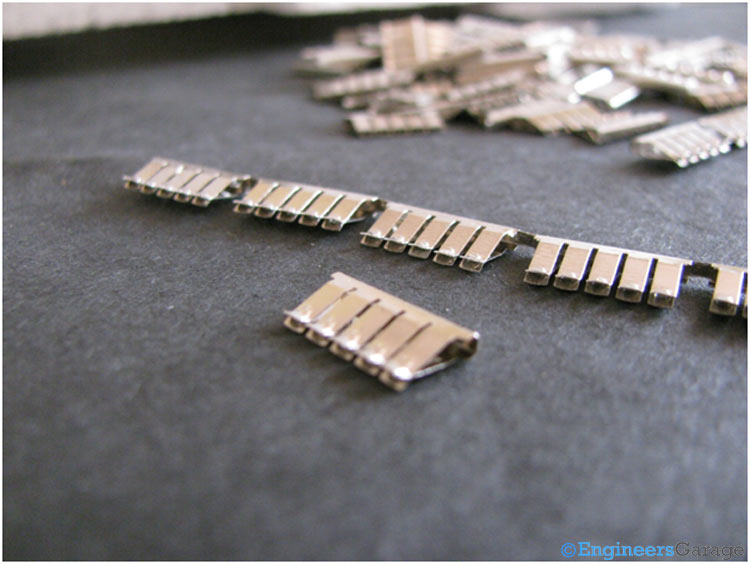

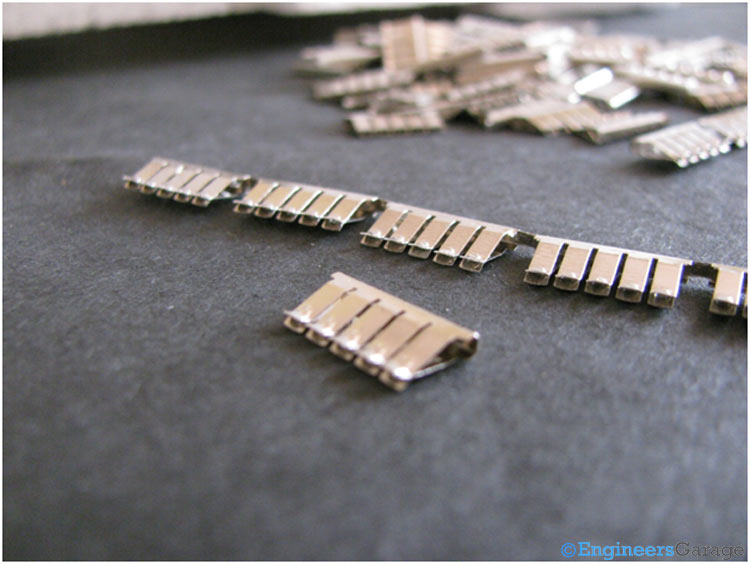

Metal Clips

The metal clips look like:

Fig. 6: Metal Clips

Clip Holding Mechanism

The clips are elastic in nature and designed in a manner that they can easily hold up a wire or a terminal of a component.

Fig. 7: Elastic Nature of Clips Hold a Wire or a Terminal

Clip Structure & Other Parts

Opening the clip wide is shown in image below.

Fig. 8: Wide View of Clip

Other Parts:

We can also divide the plastic box into pieces.

Fig. 9: Plastic Bread Board Box—Showing Bus Strips and Socket Strips

Fig. 10: Bread Board Dissected: Plastic Board and Metal Clips

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.