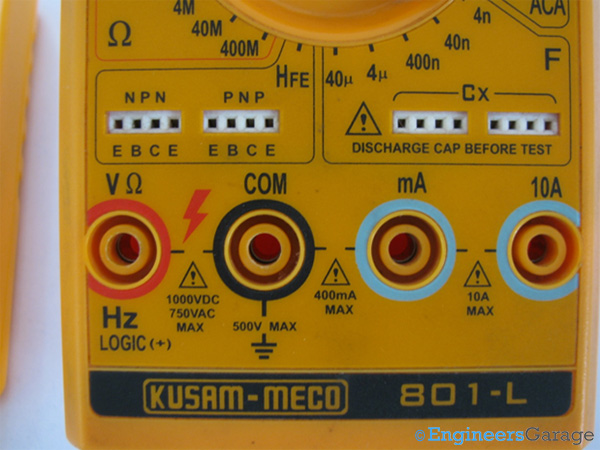

Fig. 1: Image of a Digital Multimeter

Input Ports and Battery

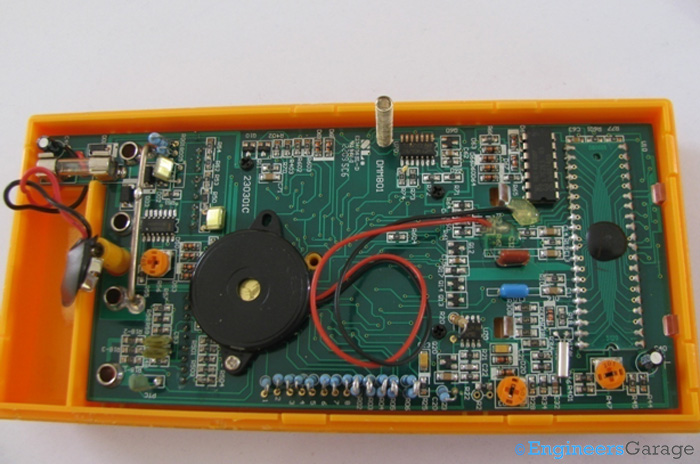

Internal Structure

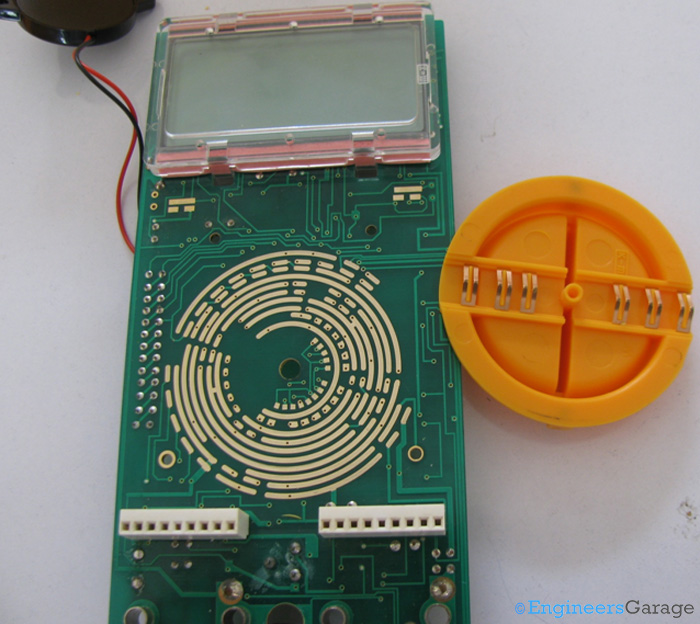

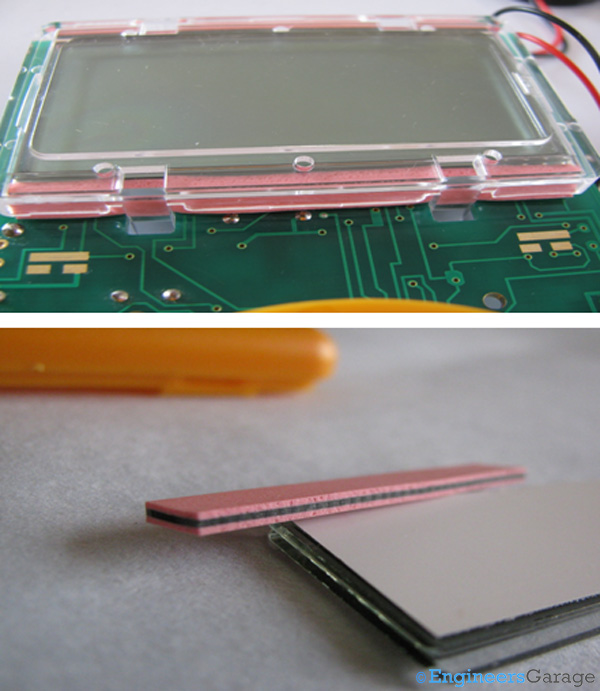

PCB

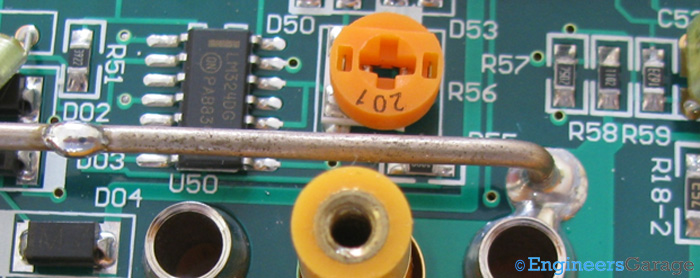

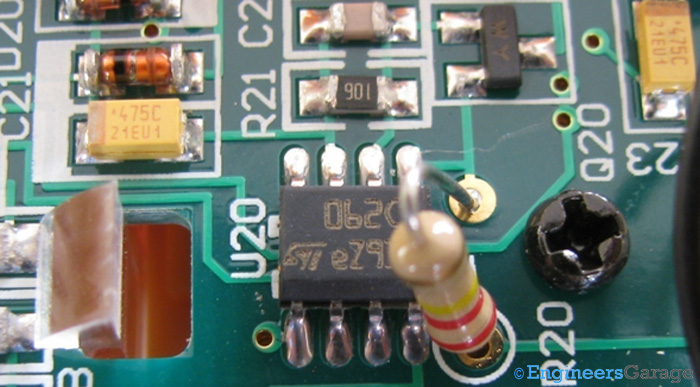

Fig. 6: A Closer View of PCB and Circuit Arrangement

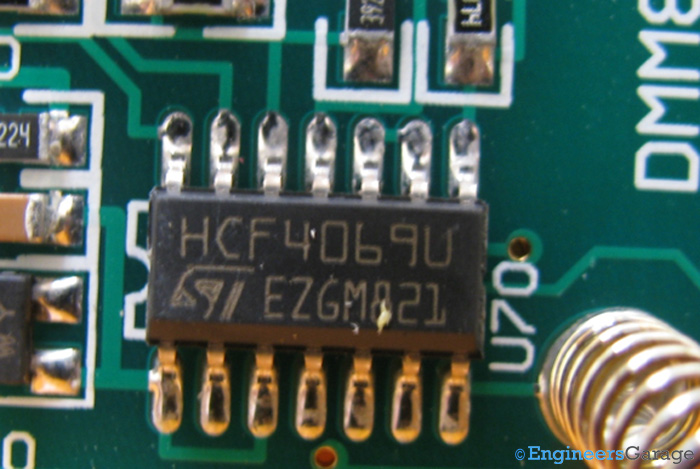

The PCB contains an assortment of various components including various types of resistors, capacitors, diodes and integrated circuits. Also, it hosts the battery, crystal oscillator, PTC, LCD and the buzzer which tests the continuity of device under test (DuT).

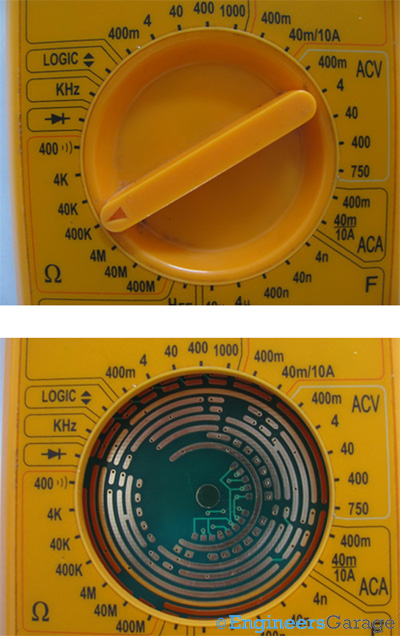

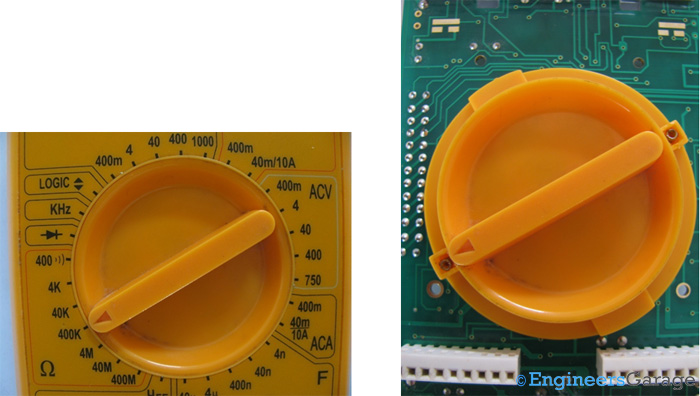

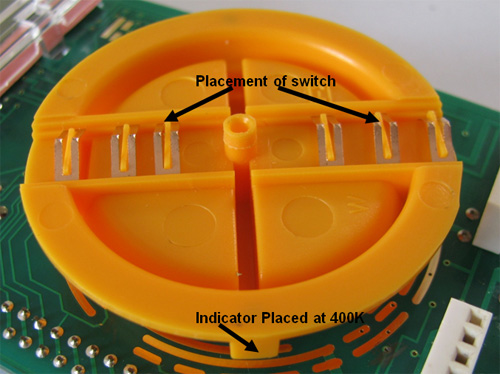

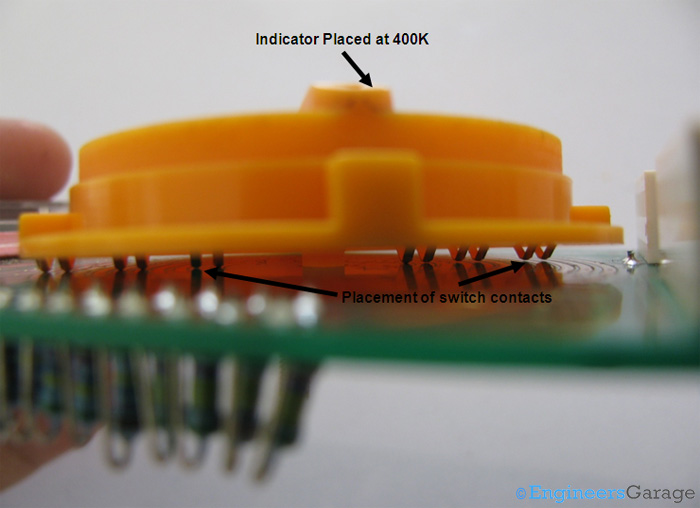

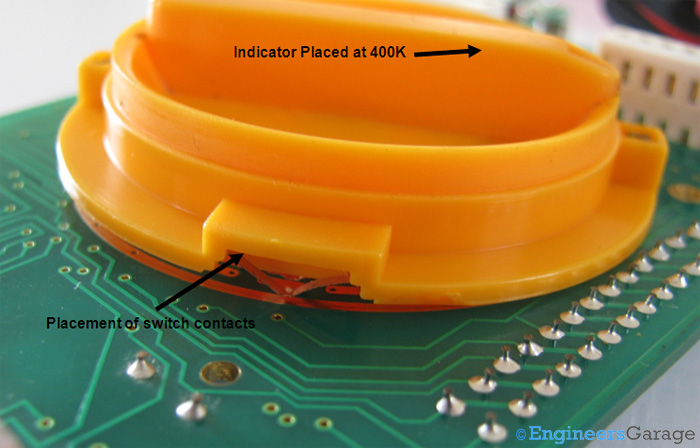

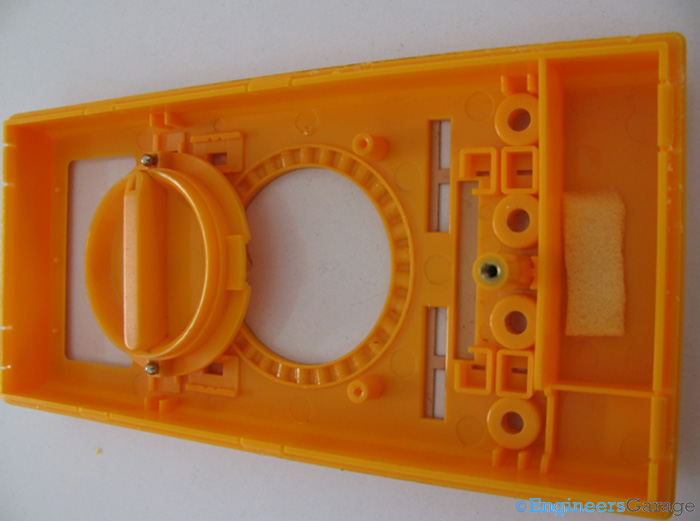

Range Selector

Conducting Circular Rings and Range/Function Selection

LCD

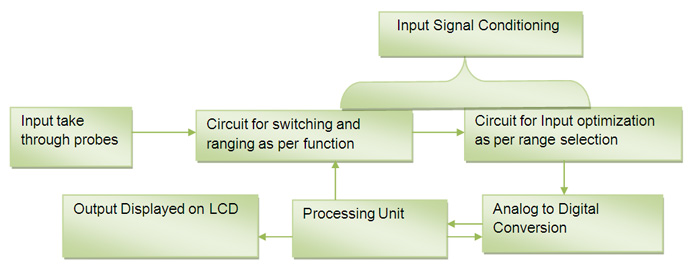

After switching the instrument on, the user rotates the knob to the desired measuring function and its range. Corresponding to the function and range selection, concentric rings of the PCB get shorted. This in turn activates that section of the PCB which is responsible for carrying out measurements in that range. Since it is a digital measuring instrument, an Analog to Digital Converter is extensively used to convert the measurements into discrete values.

Multimeters are into electronic measurement purposes since long and are expected to stay for long and get more modifications of measuring quantities. Analog multimeters were initially in trend but required calibration and human error often caused errors in measurements. With digital measurements, results are not only more accurate but can also be resolved to a high level. From voltage to currents, digital multimeters can now even measure temperature, capacitance and can now have RS232 connectors for communication to smarter machines. With newer designs rolling out every day and specialized ICs being made for each and every conceivable measurement, innovative developers continue to put more functionality into the cramped corners of the multimeter while operating at nominal power conditions and costs.

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.