Magnetic ballast is an essential component in traditional discharge lamps and tubes. In order to properly start them, an initial high current is needed which needs to be limited afterwards to prevent the lamp from blowing out. This function is performed by ballast. Electro-magnetic ballasts were one of the first components that could provide sufficient starting current to fluorescent lights or low pressure tanning lamps. Although they are being replaced by much lighter and efficient, electronic ballasts, electro-magnetic ballasts are still in trend. This article will explore the structural features of the ballast and its working.

Fig. 1: Image Showing A Typical Magnetic Ballast

Fig. 2: Casing of Magnetic Ballast

Fig. 3: Image Showing Inside View of Magnetic Ballast Casing

Internal Structure

Fig. 4: Inner Structure of Magnetic Ballast

Working of Magnetic Ballast

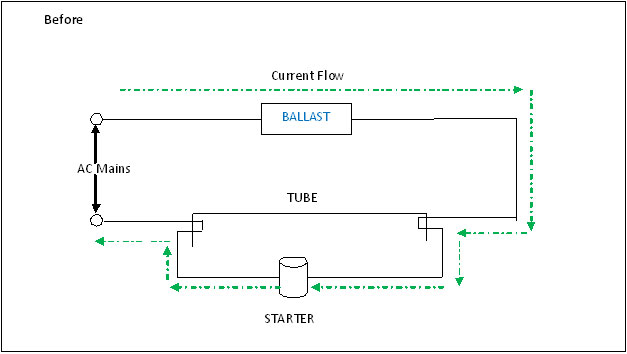

Fig. 5: Diagrammatical Figure Showing Magnetic Ballast Structure Before Current Flow

Fig. 6: DIagrammatical Figure Showing Magnetic Ballast Structure After Current Flow

But due to passage of current through the air inside the lamp, it ionizes and its resistance to current flow decreases progressively as the current goes on increasing. If this is not checked, the lamp may get shorted and even blast. This limiting again, is provided by the ballast. The inductance coil now acts as a reactance and limits the maximum current that is allowed to pass through the circuit. The greater the inductance of the coil, the more it can limit the current. The resistance goes on increasing to a maximum value after which normal current would flow through the lamp and it would continue to glow.

Coils

Fig. 7: Image Showing Coils Present Inside Magnetic Ballast

Core

Fig. 8: Magnetic Ballast Core

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.