Piezo buzzer is an electronic device commonly used to produce sound. Light weight, simple construction and low price make it usable in various applications like car/truck reversing indicator, computers, call bells etc. Piezo buzzer is based on the inverse principle of piezo electricity discovered in 1880 by Jacques and Pierre Curie. It is the phenomena of generating electricity when mechanical pressure is applied to certain materials and the vice versa is also true. Such materials are called piezo electric materials. Piezo electric materials are either naturally available or manmade. Piezoceramic is class of manmade material, which poses piezo electric effect and is widely used to make disc, the heart of piezo buzzer. When subjected to an alternating electric field they stretch or compress, in accordance with the frequency of the signal thereby producing sound.

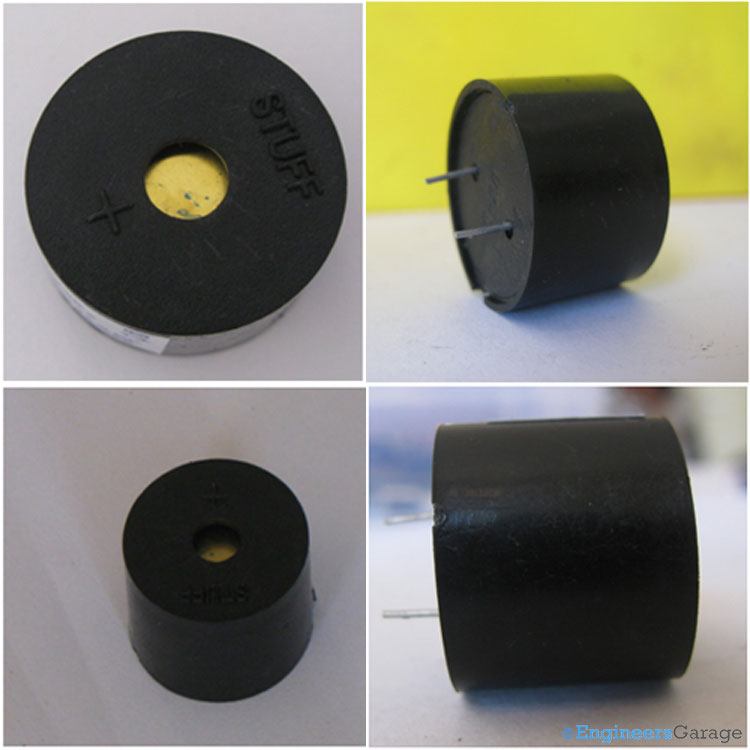

Fig. 1: Image of a Piezo Buzzer

The above image shows a very commonly used piezo buzzer also called piezo transducer operating at DC voltage. Encapsulated in a cylindrical plastic coating, it has a hole on the top face for sound to propagate. A yellow metallic disc which plays an important role in the producing sound can be seen through the hole.

Different Views

Fig. 2: Piezo Buzzer as seen from Different Angles

The above images show the buzzer at different angles. The two leads are used to supply a DC voltage.

PCB

Fig. 3: Image Showing PCB and Electronic Components of Piezo Buzzer

On removing the back plastic cover the PCB with electronic components soldered on it is shown in the image above.

Electronic Components

Fig. 4: Electronic Components Behind PCB of Piezo Buzzer

This is the opposite side of the PCB, having the necessary electronic components: a resistor, a transistor and an inductor. The input to the transducer is a low voltage DC signal, however in order to produce sound the piezoceramic disc needs oscillations of high voltage. The transistor and resistor combination works as an oscillator circuit to produce low amplitude oscillations from the DC voltage. The magnitude of these oscillations is amplified by the inductor.

Fig. 5: Image Indicating Inductor Coil of PCB

The inductor coil surrounded by tape is shown in the image above.

Diaphragm

Fig. 6: Image showing Diaphragm Attached to PCB—the Arrangement that Produces Sound

The above image shows the circular shaped diaphragm connected to the rest of the electronic components which is the source of producing sound. It consists of a metal plate made up of brass or stainless steel and a piezoceramic disc (white colored disc) of smaller radius connected to each other with a conductive adhesive. The metal plate is used because the resonance frequency of the piezo ceramic material is too high to produce audible sound.

Fig. 7: Metal Plate at Backside of Diaphragm

The above image shows the back side of the diaphragm, which is typically a metal plate.

Piezoceramic Disc

Fig. 8: Close-up Image of Piezoceramic Disc, Attached Metal Plate, and Wire Connections

The above image is a clear view of the piezoceramic disc glued to the metal plate (a small segment of the piezoceramic disc has been removed for proper understanding). The piezoceramic disc is coated by electrodes on both sides. There are three wires connected to the diaphragm: one to the metal plate and one each to the electrodes of the ceramic material. The wire connected to the metal plate is grounded. One electrode is used to provide the high amplitude oscillation signals to the ceramic disc and the second is used to provide a feedback to the oscillating circuit.

Working

Fig. 9: (Top left) Metal Disc with Piezoceramic Material Glued, (Top right) Metal disc, (Bottom left) Top of Metal Disc, (bottom right) Backside of Metal Disc

The above images in sequence shows the metal disc with piezoceramic material pasted on it , the metal disc, the front side of the piezoceramic disc, the backside of the piezoceramic disc.

Working:

When a small DC voltage is applied to the input pins, it is first converted to an oscillating signal using the combination of resistor and transistor. These oscillating signals are amplified using the inductor coil. When high voltage alternating signals are applied to the piezo ceramic disc, it causes mechanical expansion and contraction in radial direction. This causes the metal plate to bend in opposite direction. When metal plate bends and shrinks in opposite direction continuously it produces sound waves in the air.

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.