A trimmer or preset is a miniature adjustable electrical component. Trimmers can be variable resistors (potentiometers), variable capacitors, and trimmable inductors. They are common in precision circuitry like A/V components, and may need to be adjusted when the equipment is serviced. Unlike many other variable controls, trimmers are mounted directly on circuit boards, turned with a small screwdriver and rated for many fewer adjustments over their lifetime. Trimmers like trimmable inductors and trimmable capacitors are usually found in superhetrodyne radio and television receivers, in the Intermediate frequency, oscillator and RF circuits. They are adjusted into the right position during the alignment procedure of the receiver.

Trimmers come in a variety of sizes and levels of precision; for example, multi-turn trim potentiometers exist, in which it takes several turns of the adjustment screw to reach the end value, allowing for very high degrees of accuracy.

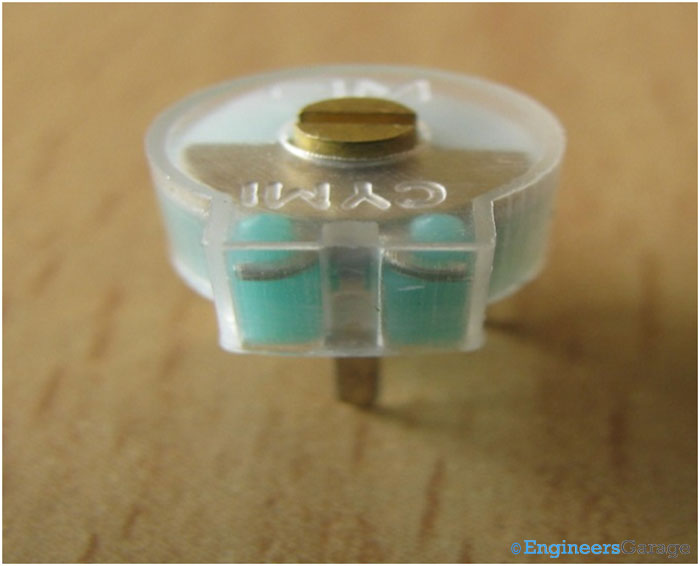

Fig. 1: A Typical Trimmer Capacitor

Trimmer capacitors are nail sized small capacitors that can be tuned within a certain range for their capacitance as per the specifications of the circuit. These capacitors can also be termed analogous to presets in terms of the functions they perform. Such variable capacitors find their application in filter tuning, small radios, car audio systems and several such instruments. The capacitance is usually adjusted by turning a screw. Trimmer capacitors are only available with very small capacitances, normally less than 100pF. It is impossible to reduce their capacitance to zero, so they are usually specified by their minimum and maximum values, for example 2-10pF.

Outer Structure

Outer structure

The capacitor explained is constituted by three pairs of metal plates and dielectrics that can be easily recognized from its outer structure. The legs, the uppermost metal plate and the screw which is used to change the capacitance, are easily observable from the first sight as the cap of the capacitor is transparent.

Now we look at the trimmer capacitor from three different views

· Top view

· Bottom view

· Lateral view

A top and bottom view of the capacitor is shown in subsequent images.

Fig. 2: Outer View of Trimmer Capacitor

Fig. 3: Bottom View of Trimmer Capacitor

The bottom view shows the legs of the capacitor and the screw & nut assembly that allows free gyration of the screw. A conventional capacitor has a two legged structure while a trimmer capacitor has a three legged structure. The third leg, which basically has two thin legs that begin at the same point, holds the middle and the bottom metal plates and keeps them intact when the screw is adjusted to change the capacitance.

Fig. 4: Image Showing Screw Attached To Grooves In Capacitor

From the picture above we can see the screw attached to the metal plate and two grooves coming out that join the metal plates to a hook on the plastic base so that the plates are kept intact and they don’t move when the screw is rotated.

Inside the Trimmer Capacitor

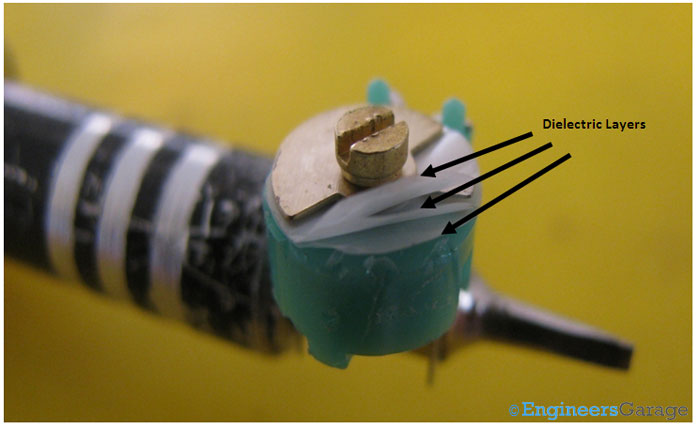

The image below shows the view on removing the transparent cap.

Fig. 5: Inner View Of Trimmer Capacitor

The plastic cap of the capacitor can be easily opened by slight mechanical force. A clearer image of the trimmer capacitor can be seen above. It can be concluded that the metal plates are below the top plate which is connected to the top of the screw and are not arranged in an alternative manner. As there are multiple dielectrics and the base can be partially seen through them.

Fig. 6: Image Showing Metal Plates and Dielectric Inside The Capacitor

When the structure comprising of metal plates and dielctrics is separated, it gets clear that the plates are semi circular in shape and the diectric used is PVC . All these entities are hinged to the screw at the centre of the strucuture.

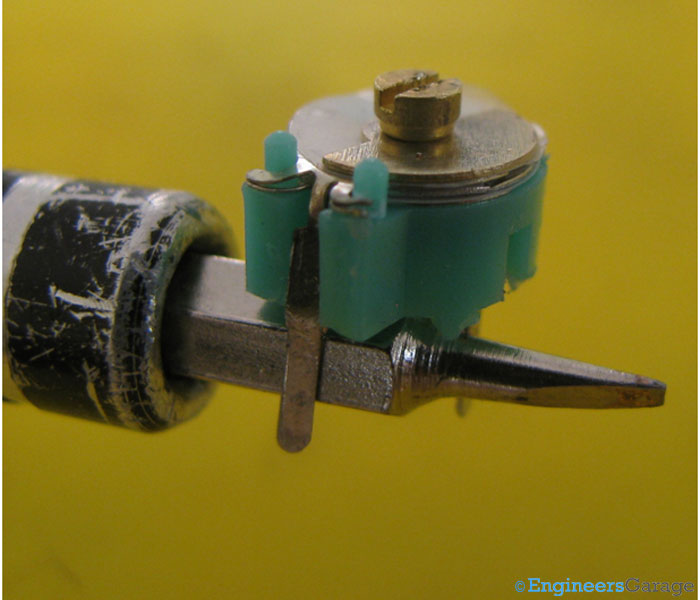

Capacitor Plates

The middle and bottom plates are hooked up to the base of the capacitor as shown:

Fig. 7: A Closer Look At Trimmer Capacitor Plates

Structure of the Core

Structure of the core of the capacitor

When this structure is opened, the arrangement of the plates and dielectrics can be seen as

Fig. 8: Image Showing Various Parts of Capacitor’s Core

In the fabrication process, the top screw is firmly attached to the uppermost metal plate.

Fig. 9: Image Showing Positioning of Metal Plate and Screw Against Each Other

Working

Working of trimmer capacitor

Trimmer capacitor’s working is as simple as its structure. The metal at the top is rotated so as to change the capacitance with the help of the screw. When the metal plate overlaps the other two semi circular shaped metal plates, the capacitance is at the highest magnitude.

Fig. 10: Image Showing How Trimmer Capacitor Works

Capacitance goes on reducing when the plate is rotated to a different position other than the overlapping and it is least when the metal plate is placed opposite to the metal plates. The change occurs as the electric field storage capacity between the metal plates changes and it gets minimized when one plate is faced opposite to the other.

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.