Every year, technology sector companies invest millions of dollars in R&D to improve their products and release new products. An important part of these products is characterized by the connectors they use. For instance, a computer requires USB and PS2 Connector, a headphone requires TRS connector and a telephone requires RJ11 connector and so on. For high quality professional sounds, XLR connector is widely preferred. The term XLR derives its name from Cannon “X” series (where it was first used). Terms “L” and “R” are derived from latch and rubber used in the connector.

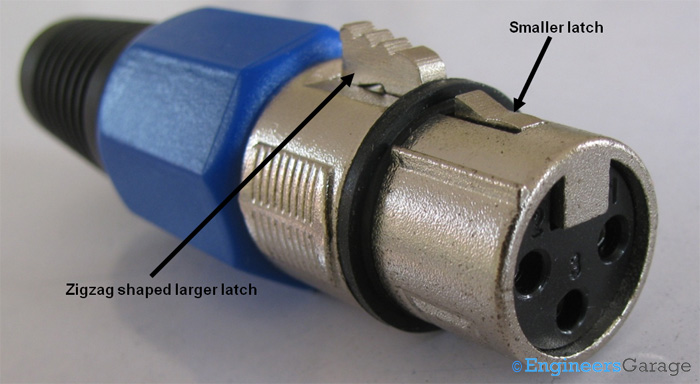

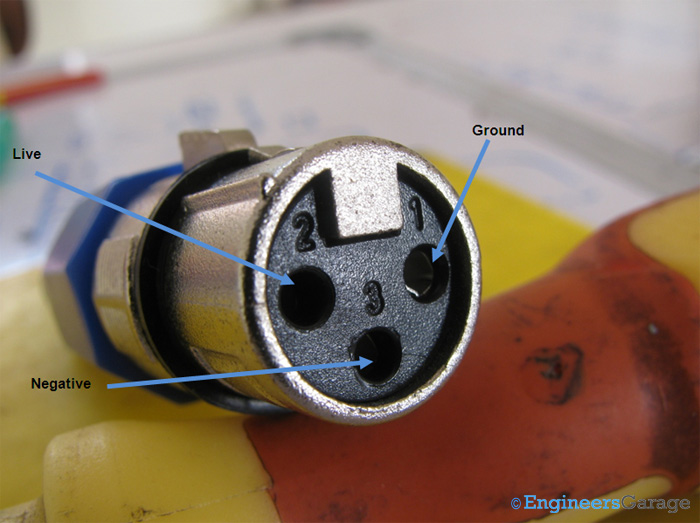

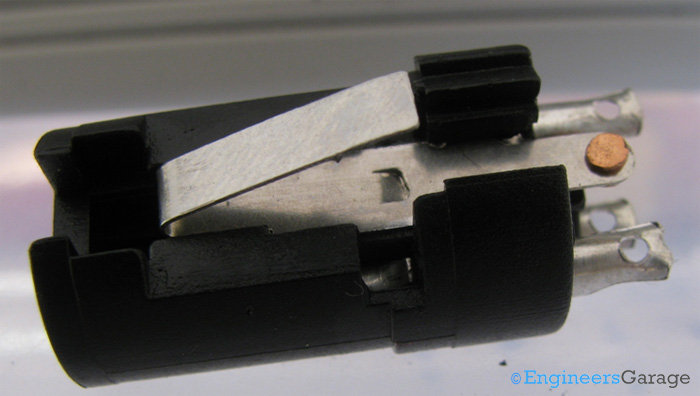

Front Structure

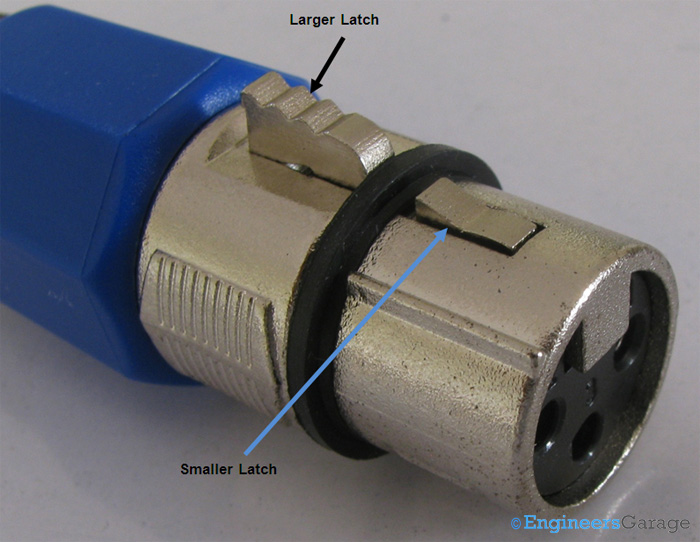

Locking the device

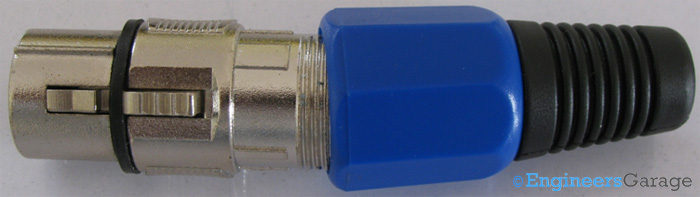

Wire Streamliner

Lever for Latch movement

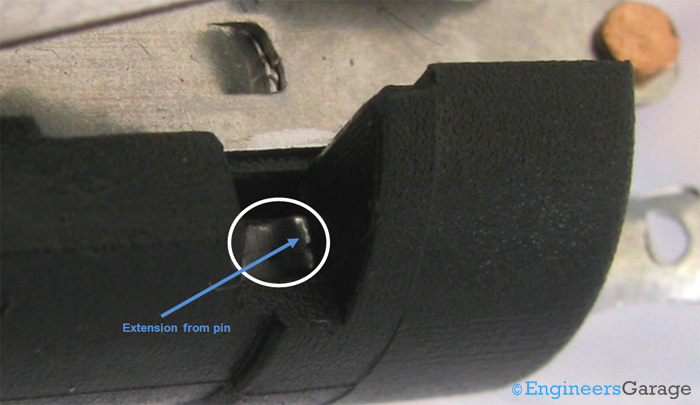

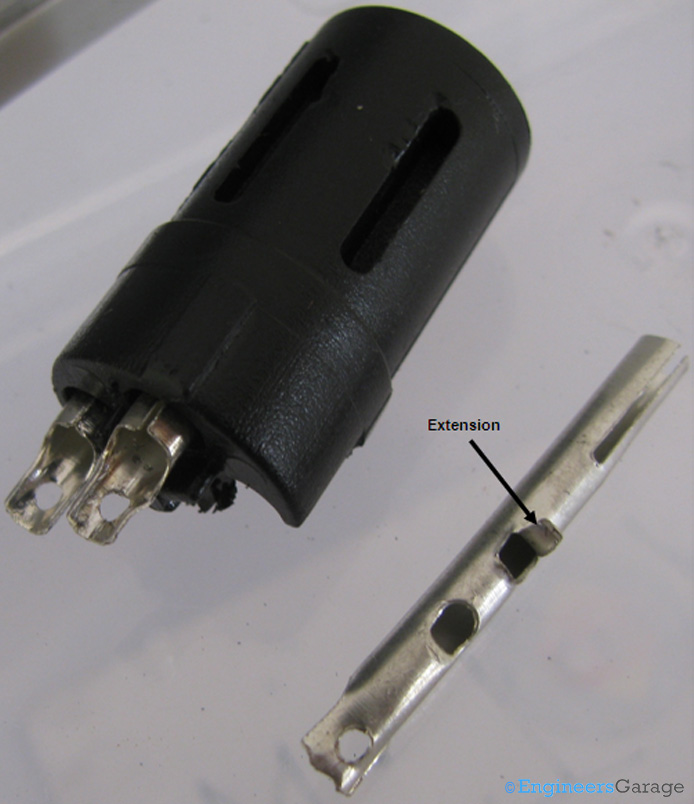

The connecting pins have a structure similar to a flute. An extension which restricts the movement inside plastic molding can be seen in the image above.

Filed Under: Insight

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.