A research team recently came up with a thin plastic membrane that keeps the rechargeable batteries from discharging when not in use. The membrane also aids in speedy recharge of the same as per its makers. The technology is yet to be patented, however, it is being reckoned for its ability to administer the flow of charge within the battery. The basic design of this battery was derived from the procedure of proteins transfer by cell membranes. It’s biggest application is being viewed in the ‘supercapacitors’ for electric cars. The membrane can prove really helpful in the various kinds of fires that damaged hoverboards of some models recently.

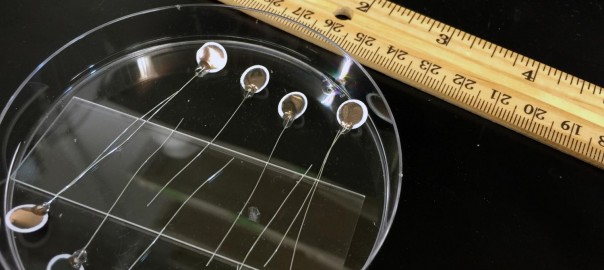

Figure 1: Supercapacitor for electric-car

Also being called as the ‘smart’ membrane, this one is supposed to be basis for a completely new class of batteries that will be way more powerful and rapidly chargeable than their present day versions. The Ohio University team of engineers likes to call it ‘redox transistor batteries’ that will help the electric vehicles in moving far and far with one single charge. They also noted that even the best electric car makers are compelled to face a performance restriction . The best pieces are known for moving 321 kilometers within first 8 hours of charging. The gas charged vehicles, on the other hand, travel same distance after spending hardly one minute over charging station. This new research will play a huge role in boosting the electric car batteries and will offer tens of miles increment on per minute of charge.

Vishnu-Baba Sundaresan, the assistant professor of mechanical and aerospace engineering in the Ohio State, adds, “That’s still an order of magnitude away from the equivalent measure in gasoline, but it’s a place to start.” The conventional batteries, these days, put a performance limit over the hybrid and electric vehicles as per him. This new technology paves a new path for pushing away that restriction and bringing a huge improvement to their performance. He further explains, “Research over the last 50-plus years has focused on advancing the chemistry of battery electrodes to increase capacity. We’ve done that, but the increase in capacity has come at the cost of robustness and the ability to rapidly charge and discharge batteries. Electric vehicle design is mature enough now that we know the limit they’re reaching is because of the chemistry of lithium-ion batteries.”

Filed Under: News

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.