PCB Design – Copper filling:

Copper pour or fill refers to an area of the printed circuit board filled with copper. Actually, copper fill is the original copper which is not etched away from the PCB. Usually, this copper fill is connected to ground plane, but not fixed for the ground plane, if we want; we can connect it to any other. This copper flows around the tracks and pads but does not belong to any track.

Fig. 1: Image of Printed Circuit Board Filled with Copper

Need:

1. To reduce the amount of the etching fluid used during the manufacturing.

2. To reduce the amount of electrical noise.

3. To reduce the crosstalk experienced by the circuit elements.

How to fill the copper pour:

• Before filling copper, first ensure the layer for example front layer, the bottom layer, or if we are using multiple layers, then inner layer1, or inner layer 2, etc.

• Select “Add filled zones” from the right toolbar.

Note: Before selecting Add filled zone, turn ON the zone display, or else it will show an error like below.

Fig. 2: Screenshot of Error Message When Zone Display is not ON

• After selecting Add filled zones, click at the first corner of the board. A properties window will appear on the screen.

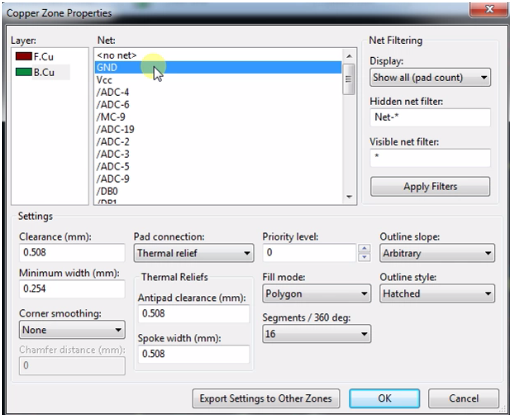

Fig. 3: Screenshot of Properties Window

• In this window, we can select layer, Net like options. Select the relevant copper layer and Net for filling the copper (GND,Vcc etc). If needed, we can select any other net also but the commonly ground is preferred to avoid noise and cross talk.

• Select fill Mode as a polygon, and select Thermal relief under pad connection. If it is required, change the remaining settings also. Select “OK”.

Note:

1. Clearance – controls the filled area between pads/traces and the nets.

2. Minimum width – controls the thinnest that the fill can be when flowing around other pads/traces.

3. Thermal Relief – controls the clearance around the ground pads.

• After closing the properties window with mouse cursor graphical line will follow. Place the graphical line by clicking at the remaining three corners and close the loop by double click at the starting point. After this, we can observe a small change in graphical line. Red or green diagonal lines follow the inside.

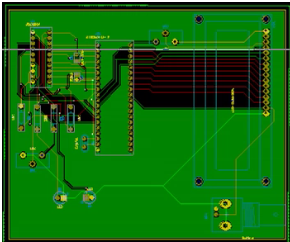

• Now we can run the DRC (Design rule check) tool. After running DRC tool, we can see some changes in Board. The board is filled with the light color layer (like green, yellow, red etc). It may look like as shown in figure given below:

Fig. 4: Image of Board is Filled with the Light Color Layer

• If we want to fill copper both sides of the board follow the given steps:

right-click on the existing board edge >> select “Zone outline” >> then go to “Zones” >>”Duplicate Zone”.

Filed Under: Tutorials

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.