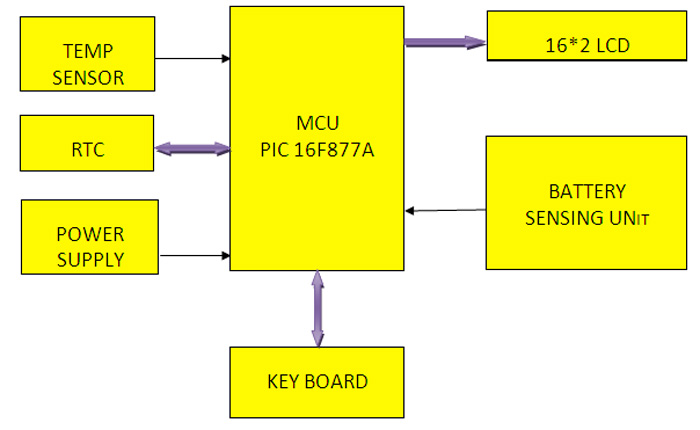

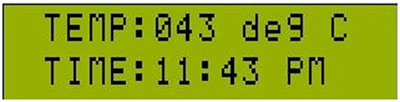

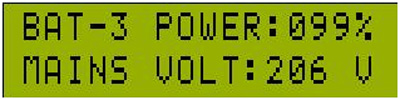

Using this system, you can remotely monitor the battery level, mains voltage, battery run time, temperature. It designed using PIC16F877A microcontroller for reducing the external components, such as external ADC, OP-AMP, large number of resistors and capacitors. Lesser external components increase the circuit response and stability. And also decrease the power consumption, noise.It is assumed that the reader has gone through the project How to get started with PIC and done all the things discussed in it.

The protection can be done by an easy manner. Temperature and battery dry run protection circuits are inbuilt. So there are no external circuits needed. It is very useful for IT industries, computer laboratories, colleges and schools.

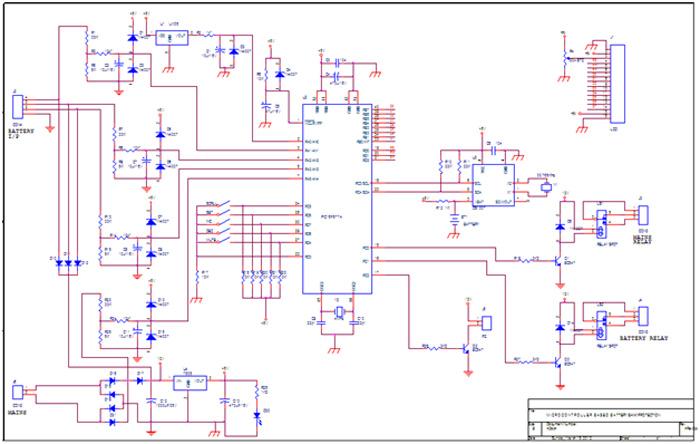

Circuit Description

How it Works?

Software & Construction

|

Files and Subroutines

|

Functionality

|

|

#include “delay.c”

|

To generate a time delay

|

|

#include”i2c_bat.h”

|

To configure master/slave port

|

|

#include”lcd_bat.h”

|

Contains the display subroutine

|

|

#include”adc_bat.h”

|

Contains the analog to digital conversion data

|

|

void control(void)

|

To control real time monitoring process

|

|

void key(void)

|

Check the status of the push button and set the real time

|

Circuit Diagrams

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.