As computing is getting cheaper and faster, machines are becoming faster and smarter. In the previous century, computers were only affordable by a small fraction of the society like large corporate or educational institutions and could only be operated by experts but, as time progressed so did technology. Today’s computers are as cheap as your average monthly rent and can even be used by a 5 year old. When they are available to such a large portion of the population, more people find better ways to integrate computing with other sectors to establish a more efficient system overall. One of the industries which has been affected by this is the Manufacturing Industry, shifting it towards fabricating parts for personal use. “Personal Fabrication” has gained momentum with the invention of 3D printers, where you can design your own parts on a CAD (Computer Aided Design) software and then actually creating a physical replica of your model using computer guided tools. Personal 3D printers are becoming really popular these days making it a common sight in educational institutions. But does it stop here? If no, what more can we do to advance this technology?

As we often do, we look towards nature to find an answer. Genetic data present in each living cell gives the cell all the information required to form an entire living organism forming entirely different parts using similar building blocks. What if the molecules of matter could be programmed in a similar way to change their properties according to what is required out of them? Like optical properties, density, elasticity, crystal structure, etc. What if individual molecules can build themselves using information which is fed to them? Matter which can build itself, heal itself and change itself when required. This is what the concept of “Programmable Matter” is trying to achieve.

Programmable Matter – Introduction

Programmable matter is a form of digital matter or ‘smart matter’ which has the ability to carry out functions like sensing, computation and actuation allowing it to change its properties dynamics. One block of programmable matter would contain thousands of tiny microbots which would interact with each other to function as a unit entity. Imagine a mechanic’s entire toolbox integrated into one device, a wrench which can turn itself into a screwdriver and then into a plier all while remaining in the mechanic’s hand. The capabilities that this concept could achieve is quite limitless and could help achieve a stage of maturity in this age of semiconductors that we live in today. Programmable matter need not necessarily be in the solid state, it can even be a liquid which can respond to code, like ferromagnetic non Newtonian fluids or even solid programmable matter mixed in viscous fluids to be used as a spray on smart mixture.

Tackling this problem could be approached from two directions:

-

The stimuli which is required to cause the change in matter could be from an external source, i.e. either by applying heat, pressure, voltage, light, electric or magnetic fields; one can manipulate the relation that the change has with the stimuli with the property of interest.

-

The second way is by programming the individual units (internal stimuli) with the computational capability so that they can compute their own change and implement it by themselves. The command can be pre-fed into them or take the command dynamically from the user or the environment. A good example of this approach is “Claytronics”.

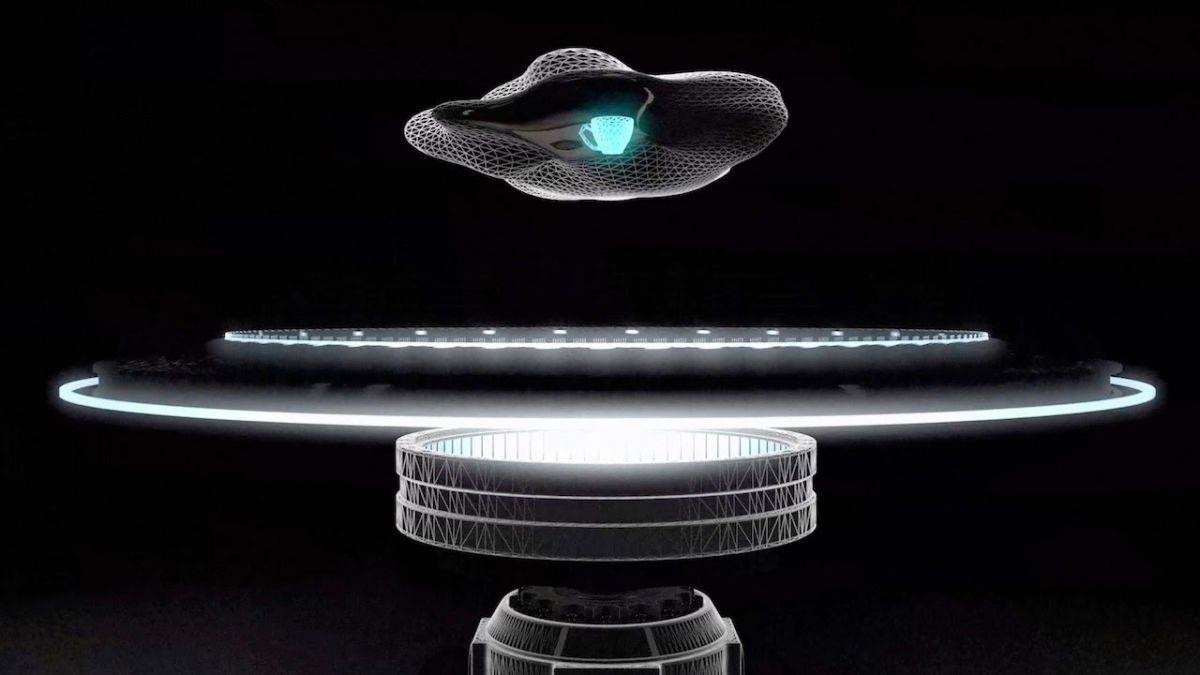

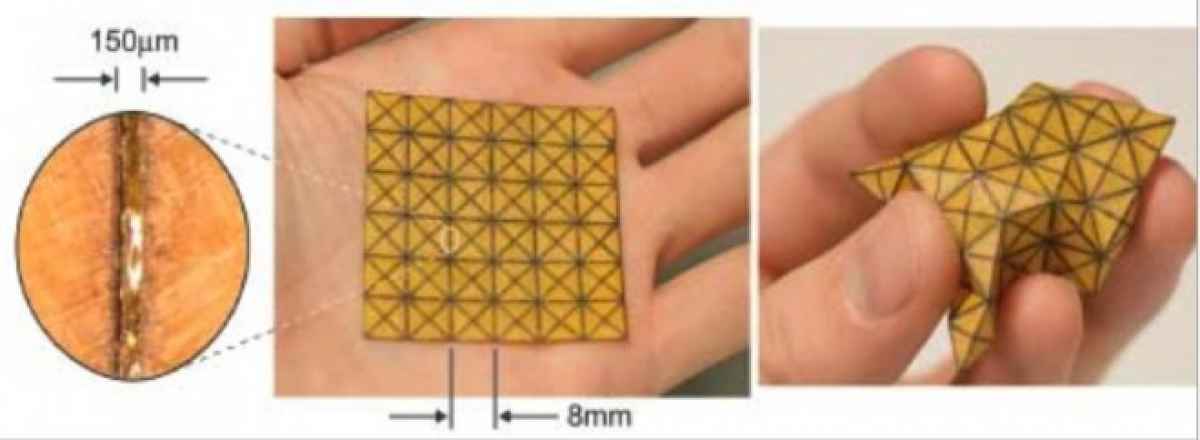

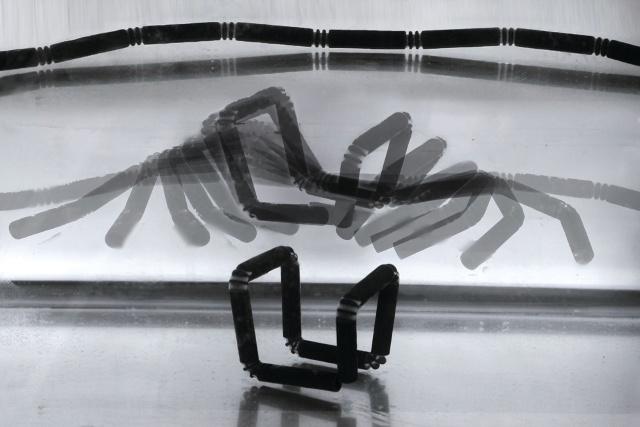

Figure 1 DARPA Origami Programming matter – foldable

In programmable matter, size is an important factor that plays a part in determining the Three-Dimensional resolution of the object. A basic unit of programmable matter

must have a power source, processing capability, communications modules, sensing and actuation etc. All this fitting into one tiny object depends on the sizes of the individual elements and are therefore differentiated from the centimeter scale to the micrometer and nanometer scales. The nanometer scale is much far ahead with the concept of quantum dots which are artificial atoms which can confine electrical charge in all three dimensions. The micrometer scale involves the utilization of MEMS based units which are tiny robots built using Nano devices.

Claytronics

Claytronics

A combination of Nano-Robotics and computer science, Claytronics blends these into tiny nanometer (10-9m) scale robots which can interact with each other to form into physical objects as demanded by the user. Each individual Nano robot behaves like an atom or a basic building block of the object and hence they are called claytronic atoms or “Catoms”. Each Catom forms a part of a large computerized network communicating with the other catoms and identifying itself based on its assigned function. With the help of catoms, matter can take on any shape imaginable. The ring on your finger can turn into a bottle opener and a spatula in a kitchen can become a knife. If Claytronics is implemented through biological matter, you can even turn your food into whatever you want to eat. Claytronics is a current hot topic of research much of which is being done at the Carnegie Melon University, Intel Research Labs and DARPA (Defense Advanced Research Projects Agency) who hope to bring this concept into reality in next few decades. DARPA though is trying to develop claytronics for defense and combat purposes, the most popular of them being the project of shape shifting robots which can flow like mercury through the smallest of openings (much like the evil liquefying T-1000 robots from Terminator – 2).

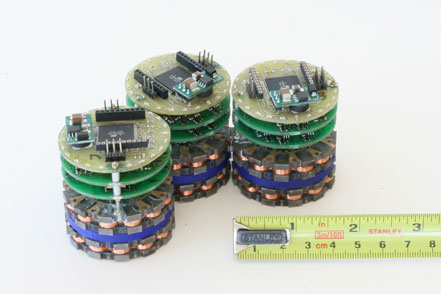

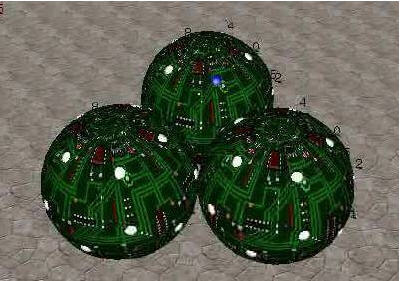

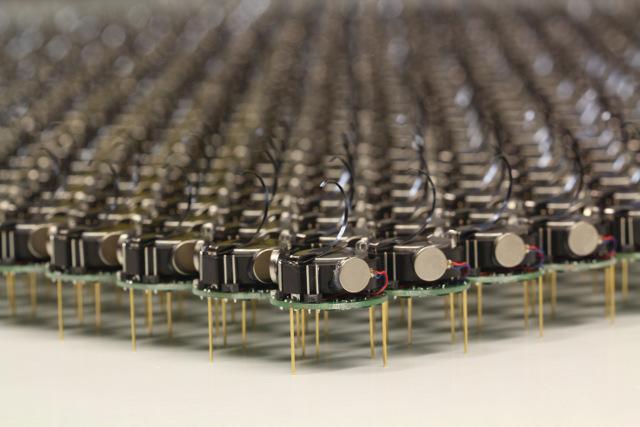

There are many complexities involved with the employment of claytronics. Complex software implementation is one of them. To give the Catoms the instructions we must first create the logic of the command and the logic to create a 3D object from millions of identical elements is not that straight forward. One of the problems is, the catoms to identify their individual function. Taking a hammer for example, how will the catoms decide which ones form the head and the ones for the handle. This forms a function assignment complication and will need to take into account the spatial locations of all the catoms, the orientation of the final product and the paths involved (to avoid path interference). Current Research is being focused on the concept of Modular Reconfigurable Robotics (MRR) combined with a complex high level programming called “Locally Distributed Predicates”. In 2005, researchers developed 44mm diameter cylindrical catoms which would bind to each other through electromagnet attraction. But, with the current shrinking of electronics, it is possible to fabricate 1mm diameter cylindrical catoms produced by the process of photolithography and be controlled by electromagnetic attraction and repulsion. The electromagnets are placed along the circumference of the cylinder (24 in number). Researchers at Carnegie Melon University have developed various prototypes of catoms in different shapes, cubes, cylinders, spheres, balloons, etc.

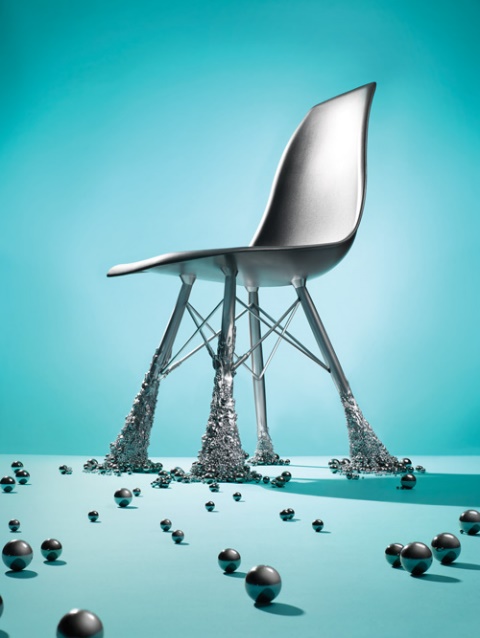

Figure 3 Cylindrical and Spherical MEMS based Catom units

Application

Application Highlights – 3D Faxing, Video Interfacing

Let us try to imagine these through examples. Suppose your company, located in India has created a new design for a fuel injection valve and want to present it to your customer, an automobile company in Japan. The conventional way would be to mail them the design drafts and CAD model which they would again have to analyze and recreate in their environment. But, with 3D faxing, you could place the 3D model of the product on a slushy mass of Catoms, in India, which would scan the spatial information from the object and communicate it to the fax machine in Japan. The machine in Japan would recreate the 3D object using the integration of the catoms on the receiving end forming an exact physical replica of the model.

Now imagine instead of an inanimate object imagine your own movements are scanned by different sensors and data is communicated to the receiver. The catoms would create a replica of your body and live track your movements to imitate through to the Claytronic replica. This gives a whole new dimension to video chatting. Soldiers posted in faraway stations can now witness their newborn babies which they otherwise would miss or for teachers from cities to take classes for the less privileged in rural areas (if there are any rural areas left by that time) or bring video games to life.

Conclusion

Programmable Matter is a far off concept which was a decade ago just a Sci-Fi concept. Now that research is bridging the gap, it is important to comprehend the implications it will have on the society. It will be as important as the invention of the computer or the internet. Looking at the similarities they possess, both find application in virtually any field that there is, both of them can be programmed to synchronize with the specific user’s needs. So we can assume the future of programmable matter by comparing it with the road which computing took. Although developments are taking place at a rapid pace (according to the Moore’s Law), it will take quite some time to become a commercial reality. Computers also did take a few decades to transition from large, expensive lab equipment to being the general household indispensable.

Just like computing, the pros being numerous, there is always a big concern, Security! Hacking computers pose big problems but, what if a system of catoms are hacked into? Your own chair could hold you as a hostage. This will pose a problem but not immediately and such a problem has not stopped computing from booming. Just as this technology grows, as will the security measures which prevent hacking. The next problem which may arise is that of unemployment, not because of lack of skill, but, there will be nothing left to do by person.

We have been on earth for a minute fraction of its existence and now we are on the brink of creating a digital form of life. It really portrays the true capability of what we can achieve if we can just imagine it. The maturity of Programmable matter may or may not happen during our generation but, whenever it does come out it will be for the better and propel human development into a new dimension.

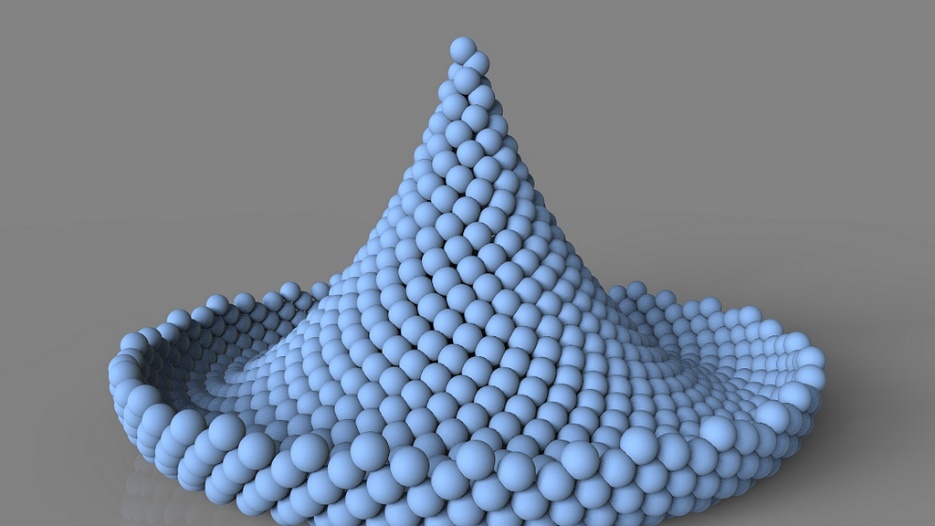

Figure 4 Self folding straw created at MIT, Boston, USA

Filed Under: Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.