Second application of IRRCS and probably the most interesting application because it includes everything remote control, 89C51 based stepper motor control, LCD display. 89C51 controls all three parameters (RPM, direction, no. of revolutions) of bipolar stepper motor and also indicates every action on LCD.

Know how to interface LCD with microcontroller 89C51

Know how to control bipolar stepper motor

Transmitter:-

In this application of IRRCS only 6 switches out of 16 are used because 6 switches can perform most of the required functions. Please refer the table

|

Switch |

Function |

|

SW1 |

Rotate motor clockwise |

|

SW2 |

Rotate motor anticlockwise |

|

SW3 |

Increase the RPM of motor |

|

SW4 |

Decrease the RPM of motor |

|

SW5 |

Increase number of rotations |

|

SW6 |

Decrease number of rotations |

The operation remains same as explained before controller will generate and transmit a specific code every time when any key is pressed. So five different codes assign to each key and they are transmitted over IR channel when key is pressed.

Receiver:-

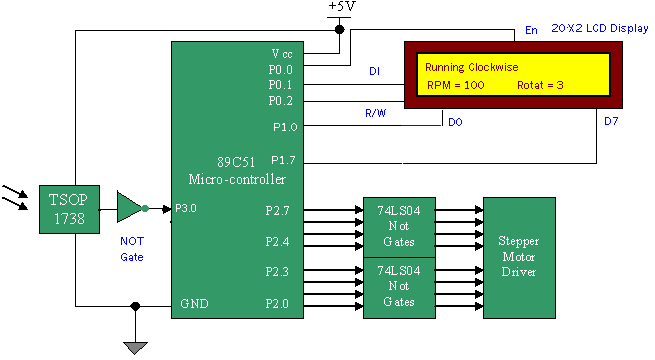

The block diagram is shown in Circuit Diagram Tab1.

Connections:- Main components are IR sensor (TSOP 1738), 89C51 micro-controller, Not gate ICs 74LS04, 20×2LCD display and stepper motor driver.

The inverted o/p of sensor is connected to RXD (P3.0) pin of 89C51. Stepper motor driver is connected with port P2 through not gates (works as buffer). The data pins (D0-D7) of LCD are connected with port P1 and the control signals (R/W, DI, En) are generated by port P0 pins.

Operation: – IR sensor will demodulate 38KHz IR signal extracts the code and give it to micro controller.

Micro-controller is working as a serial data receiver. It will read the code and compare it and as the match found it will call that specific subroutine like rotate clockwise, rotate anticlockwise, increase/decrease RPM.

LCD is used to display three things direction of rotation, current RPM and no. of rotations. When motor is stopped current RPM and no. of rotations are displayed in second line of LCD as shown in figure. Then whenever you press SW1 or SW2, in the first line of LCD message is displayed “running clockwise/running anticlockwise”.

· On pressing key SW1 (or SW2) on remote control, it will generate and transmit a specific code

· This code will be demodulated by IR sensor and given to micro-controller. Micro-controller is continuously waiting for any code to arrive. When it receives the code it will switch to particular subroutine and start rotating motor clockwise with current RPM. It also displays current RPM and no. of rotations on LCD display. Motor will rotate till no. of rotations is completed. Then it will stop automatically.

· Now if you press SW3 or SW4 RPM will be incremented/decremented that you can see on display

· Again when you press SW1/SW2 motor will start rotating with changed RPM.

· Same thing will happen when you change no. of rotations.

Circuit Diagrams

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.