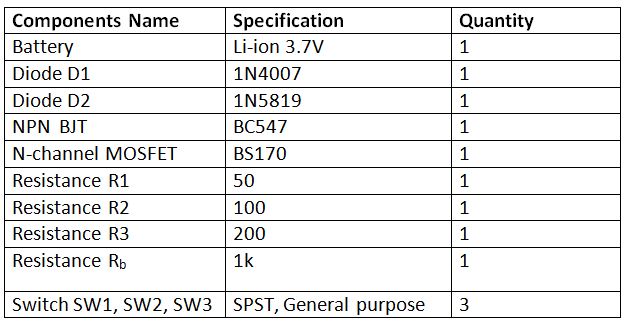

Components Required

These are the following methods for designing the battery protection circuit –

1. DIODE –

The simplest way to design a battery protection circuit is by using a diode. A diode conducts current only in one direction and gets open circuited for reverse polarity. So if a diode is connected in series between the battery and the load circuit, it will allow conduction of current only for one polarity. The diode will get forward biased and allow the flow of current in the load circuit only when the Anode of the battery will be connected to the Anode of the diode. If the Cathode of the battery will be connected to the Anode of the diode, the diode will get reverse biased and stop the conduction of current in the load circuit. This will save the load or any device which is connected to the battery. So diode should be connected so that the cathode of the diode is connected at the load circuit and the battery connector is attached to the anode of the diode. The 1N4007 diode can be used for the reverse battery protection. The 1N4007 diode has a voltage drop of around 0.7 V and maximum forward current of 1A.

Fig. 2: Circuit Diagram of IN4007 based Reverse Battery Protection

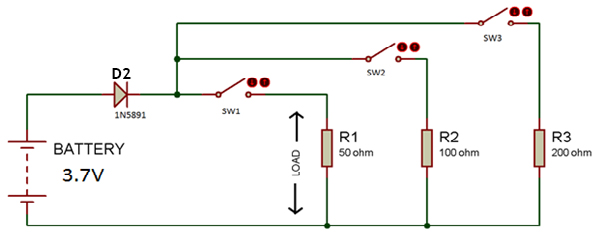

During the experiment a 3.7 V Li-ion battery is used which can provide 3.3 V supply voltage. A 1N4007 diode is connected in series to the battery such that Anode of the battery is connected to the Anode of the diode. Different load resistances are connected to the battery and diode circuit through switches and the circuit connections are completed by connecting the common ground to the cathode of the battery.

Fig. 3: Prototype of Diode based Reverse Polarity Protection

So, Input voltage, Vin = 3.3 V, On measuring voltage drop across the diode and current across the load resistances individually, following results are found –

Fig. 4: Table Listing Voltage Drop Across 1N4007 Diode and Load Current for Different Loads

From the above results, it can be analyzed that the diode takes more voltage drop across it as current demand at the output load increases. To reduce the voltage drop, a Schottky diode can be used which has less forward voltage drop as compared to the 1N4007 diode.

Fig. 5: Circuit Diagram of 1N5819 based Reverse Battery Protection

If the 1N4007 diode is replaced with the 1N5819 Schottky diode in the circuit following results are obtained –

Input voltage, Vin = 3.3V

From the above result, it can be analyzed that the 1N5819 diode will take more voltage drop across it as the current demand increases at the output load. But the forward voltage drop of Schottky diode is less compared to the 1N4007 diode.

Drawbacks of using diode circuit

Solution

2. Using N-channel MOSFET – BS170

The third way to design protection circuit is by using N-Channel MOSFET. The NMOS conducts current when there is a positive voltage at its Gate terminal. Otherwise, the NMOS remains in an open circuit condition. In MOSFET an intrinsic body diode is present which conducts when it is forward biased. So NMOS can be used as a switching transistor for making reverse battery protection circuit. The NMOS generally have less ON resistance (rDS). Due to this, it has less voltage drop in the full conducting state. N-MOSFET can also handle the high load as compared to diode or BJT.

Note: The schematics can be found under the “Circuit Diagram” tab.

So when the battery is attached correctly then MOSFET gets turned on. On reversing the battery the gate terminal is low which turns off the MOSFET and load is disconnected from the battery.

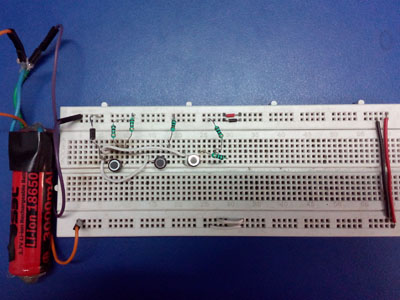

Fig. 7: Prototype of Reverse Polarity Protection Circuit Using N MOSFET on Breadboard

During the experiment a 3.7 V Li-ion battery is used which can provide 3.3 V supply voltage. A BS170 NMOS is used for reverse battery protection. The load resistances are connected via switches between the Gate terminal and the Drain terminal of the NMOS. The battery is attached to the Gate terminal and the Source terminal of the NMOS. The NMOS conducts only when the anode of the battery is connected to the base of the NMOS. If the cathode of the battery is connected to the base of the NMOS, the NMOS goes in off condition cutting the supply voltage to the load.

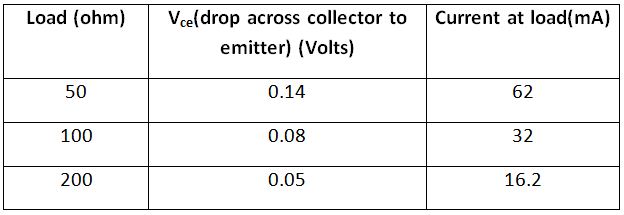

So, Input voltage, Vin = 3.3 V, On measuring voltage drop across the transistor and current across the load resistances individually, following results are found –

Fig. 8: Table listing Vds and Load Current for different loads

Drawback of using nMOSFET

Solution

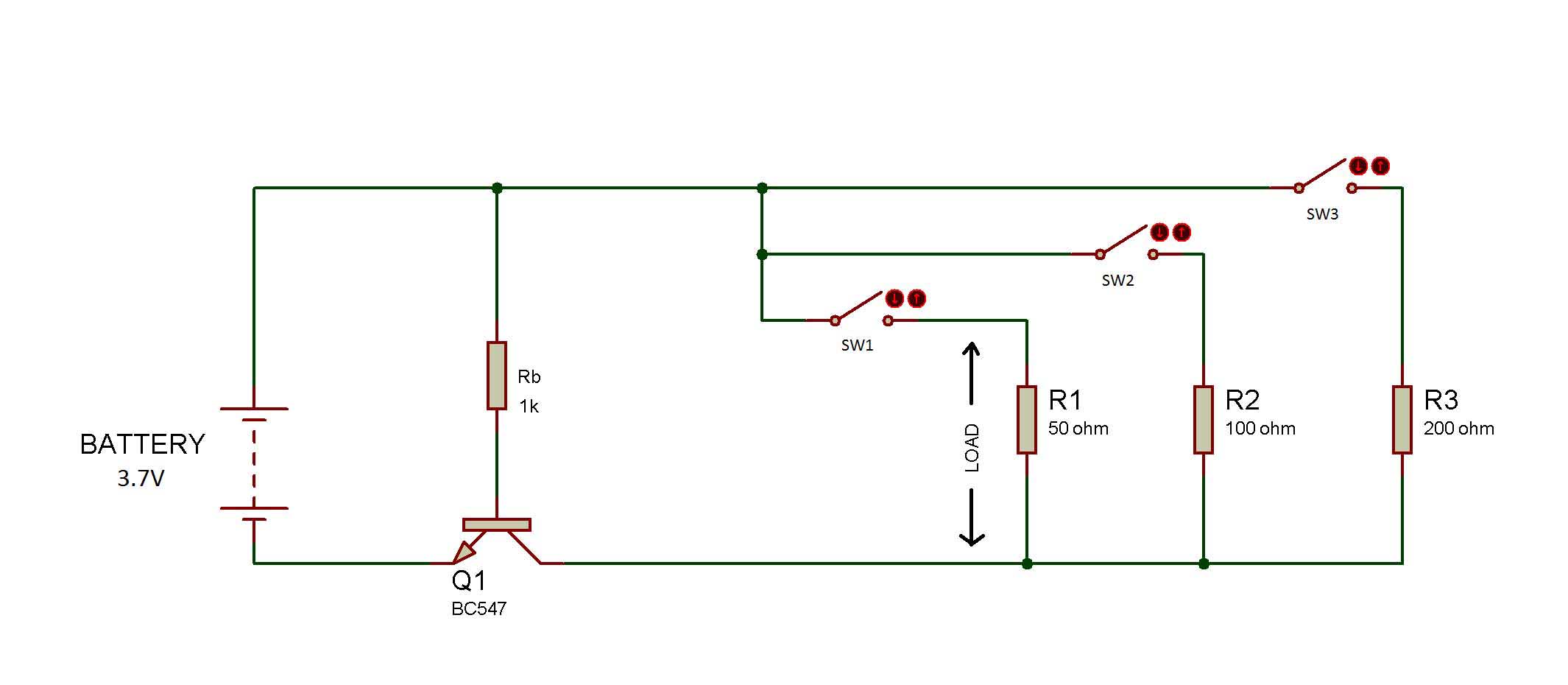

3. Using NPN BJT(bipolar junction transistor) – BC547

During the experiment, BC547 is used for the reverse battery protection. The transistor is connected in the circuit so that the load circuit is connected between the base and collector of the transistor and the battery is attached to the base and the emitter of the transistor. A pull-up resistor is used at the base of the transistor, so that base could be properly biased. When the battery is attached such that the anode of the battery is connected to the base of the transistor, the forward voltage at the base switches the transistor to ON condition and current starts flowing from collector to the emitter.

This completes the circuit and the load gets the input supply. When the cathode of the battery is connected to the base of the transistor, the base of the transistor is not biased and the transistor switches to the OFF condition. There remains no flow of current between the collector and the emitter of the transistor and the load circuit gets open. This will save the load/device from the reverse current.

Fig. 9: Prototype of Reverse Polarity Protection Circuit Using BJT on Breadboard

During the experiment a 3.7 V Li-ion battery is used which can provide 3.3 V supply voltage. A BC547 transistor is connected such that the load resistances are connected between the base and the collector of the transistor and the battery connectors are connected between the base and emitter of the transistor.

Drawbacks of using BC547

Solution

Conclusion –

You may also like:

Circuit Diagrams

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.