How to deal with any unknown stepper motor? This section deals with a special procedure that can be useful to find out the type of stepper motor, its terminals, its coil sequence, its step resolution and everything about stepper motor. if anyone have a steppe motor that doesn’t have any specifications then after going through this section…

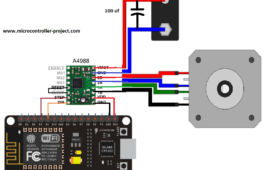

Nodemcu esp8266 stepper motor NEMA 17 controlled over WiFi

This tutorial is about controlling stepper motor over WiFi through desktop or mobile web browser using nodemcu esp8266 WiFi module. Nodemcu will work as a server and it will serve a web page. Web page contains the stepper motor control buttons. Stepper motor takes steps to complete one full 360 degree rotation. Number of steps…

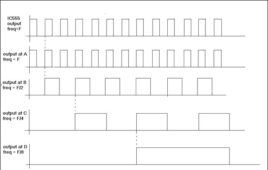

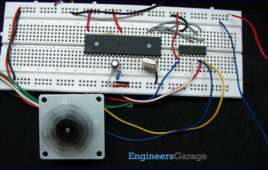

Simple Stepper Motor Driver using 555 Timer IC

The circuit presented here rotates stepper motor and varies its RPM (speed). It does not use any micro controller (or micro processor) or any programmable digital device also it does not require any software program to generate sequence of pulses. It drives stepper motor using simple, easily available and commonly used components and ICs like IC555, decade counter, OR gate, current driver chip etc. That is why the name given simple stepper motor driver.

Light Tracker Demonstration

Electricity is the most required and important element of human life. We cannot imagine our day to day life without electricity. Electricity is generated using conventional (coal, diesel) and non conventional (water, wind, sunlight) energy sources. The recent and latest trend is to generate electricity from solar energy. The solar panel (made up of solar-photovoltaic cells) converts solar energy in to electrical

Antenna Tracking System for Airborne Vehicles in UHF Communication Range

The purpose of this project is to develop an antenna tracking system for UHF communication signals. Antenna reduce human involvement and it help to guide a track in exact position of a system under consideration. For this vehicle used like unmanned air vehicle, Drone, ground vehicle and also can use a satellite system.

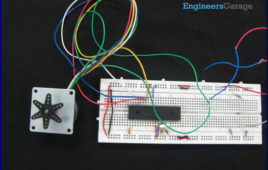

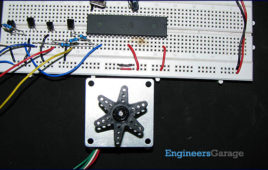

Speed and Direction Control of Stepper Motor using AVR Microcontroller- (Part 25/46)

Stepper motor can be termed as digital motor because it operates on pulses. Unlike AC or DC motor that rotates continuously, stepper motor rotates in steps. It rotates in number of steps as per applied number of pulses. The common terminal is connected to –Ve (Gnd) terminal.So as we apply this four steps sequence continuously, the motor will rotate clockwise or anticlockwise. Now to change the speed of motor we have to change pulse repetition frequency (PRF) that is the frequency of applied pulses. If PRF is increased the pulse duration decreases and speed increases and vice versa. So this project demonstrates how to vary the speed and change the direction of given stepper motor using AVR microcontroller ATmega32

Motion Controller using Stepper Motor

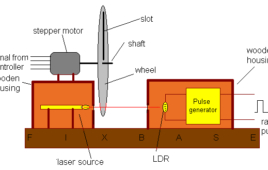

This system is the example of close loop control system for maintains the speed of stepper motor constant. The speed of stepper motor is sensed and feedback to controller. Controller will compare it with set value and if there is deviation then it will either increase or decrease the speed.In most of the industries the constant speed of motor is required and that should not be fall / exceed beyond specified limit. to get the precise RPM and control stepper motor is the best.The stepper motor is placed on top of laser as shown. The slotted wheel is coupled with the shaft of motor. The wheel is such a big that it can interrupt the laser beam falling on LDR. Now as the motor rotates the slotted wheel also rotates. The beam will fall on LDR only when the slot comes. This will produce one pulse. So every time when slot come in line with LDR and laser, one pulse is produced. Thus the rotation of motor is converted in to pulse that can be counted.

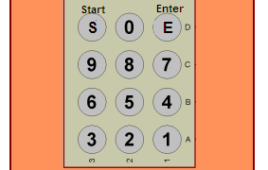

Stepper motor drive Panel

Here is the application that drives unipolar stepper motor as one enters desire no of rotations and desire RPM. This circuit rotates any unipolar stepper motor for no. Of rotations at set RPM both entered by user. Any stepper motor has basically three parameters that we can change direction, no of rotations and RPM. All these three…

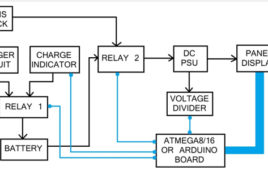

Industrial control panel for Unipolar Stepper Motor

Here given project is the real control panel for any unipolar stepper motor which is designed to run motor at lower RPM (as much as upto 10 RPM) to take greater load and provide extra heavy torque. This project is for specialize stepper motor which has technical specifications like Voltage ratings: – from 5 to…

Wireless Stepper Motor Speed Control using Laser and IC555

An interesting project explaining how can one control speed of a stepper motor from a remote place without using any wires. A LASER and LDR are used for this purpose. From the transmitter, low frequency pulses are sent to the receiver using LASER diode. On the receiver side, a LDR will receive these pulses which will further trigger mono stable multi-vibrator to regenerate same pulses. These pulses will drive the stepper motor through driver circuit. So as anyone changes pulse frequency from transmitter, the stepper motor speed will change accordingly. The project uses a pulse generator, LASER, LDR, monostable multi-vibrator, current drive, stepper motor, counter and OR gates.

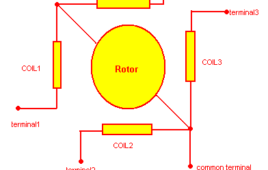

Insight – How stepper motor works

Like other motors a stepper motor also converts the electrical power into mechanical rotation. A stepper motor rotates in distinct steps where each step is a fraction of a full circle. Stepper motors are driven with pulses and one set of pulses can move the stepper motor by one step only.The top and bottom mounting plates made up of aluminum with stator in between. The rotor shaft and wires are coming out. A Stepper motor has a stator and a rotor. The rotor has a permanent magnet attached to it. The stator is made up of coils as shown in the image. There are eight coils in this motor. Every coil in the motor behaves as an electromagnet, when they are energized by electrical pulses.

How to interface Stepper Motor with PIC18F4550 Microcontroller- (Part 13/25)

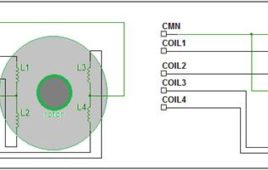

A Stepper Motor is a brushless, synchronous DC motor which divides a full rotation into a number of steps. For detailed information on working, types and stepping modes, refer the article on Stepper Motors. Here the operation of a unipolar Stepper motor with PIC18F4550 microcontroller has been explained.As stated earlier, a Stepper motor rotates step by step. Each stepper motor has a defined step angle which is the minimum degree of rotation in a single step. This step angle depends on the internal construction of the motor. If a stepper motor has a step angle of 1.8°, then it would need 200 steps for a complete circular rotation. For control operation, construction and stepping modes, refer the article on Stepper Motors.The stepper motor consists of a Rotor and four Stators. The stators are rounded with center-taped winding. The center-taped terminals are known Common terminals. Thus a unipolar stepper motor consists of total 6 wire-ends (four wires for coils and two for the common ends).

How to control Stepper Motor using ULN2003 and 8051 Microcontroller (AT89C51)- (Part 17/45)

Stepper motor is a variable reluctance DC motor. When correct input sequence of signal is given to the motor, it starts rotation in steps. (For more detail refer Unipolar Stepper motor interfacing with microcontroller AT89C51). ULN2003 is high voltage, high current Darlington arrays each containing seven open collector Darlington pairs with common emitters. Here it…

How to interface Stepper Motor with 8051 Microcontroller (AT89C51)- (Part 16/45)

Stepper motor is one of the commonly used motors for precise angular movement. The advantage of using a stepper motor is that the angular position of the motor [[wysiwyg_imageupload::]]shaft can be controlled without any feedback mechanism. Stepper motors are widely used in industrial and commercial applications. They are also commonly used as in drive systems of autonomous robots.This article explains the unipolar stepper motor interfacing with AT89C51 microcontroller. The microcontroller is programmed to rotate the stepper in wave drive and half drive stepping modes. For basic concepts and working of a stepper motor, refer the article on Stepper Motors. A Unipolar Stepper Motor is rotated by energizing the stator coils in a sequence. In unipolar stepper, the direction of current in stator coils is not required to be controlled by the driving circuit. Just applying the voltage signals across the motor coils or motor leads in a sequence is sufficient to drive the motor.

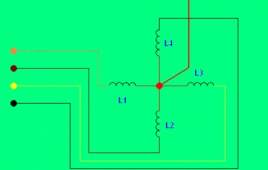

Stepper Motor : Basics, Types and Working

A stepper motor or a step motor is a brushless, synchronous motor which divides a full rotation into a number of steps. Unlike a brushless DC motor which rotates continuously when a fixed DC voltage is applied to it, a step motor rotates in discrete step angles.The stepper motor can be controlled with or without feedback. Stepper motors work on the principle of electromagnetism. There is a soft iron or magnetic rotor shaft surrounded by the electromagnetic stators. The rotor and stator have poles which may be teethed or not depending upon the type of stepper. When the stators are energized the rotor moves to align itself along with the stator or moves to have a minimum gap with the stator.

Remote Stepper Motor controller with LCD

Second application of IRRCS and probably the most interesting application because it includes everything remote control, 89C51 based stepper motor control, LCD display. 89C51 controls all three parameters (RPM, direction, no. of revolutions) of bipolar stepper motor and also indicates every action on LCD. Know how to interface LCD with microcontroller 89C51 Know how…

Wireless Stepper motor controller

This is actual wireless application because RF interface is used instead of IR to overcome all the drawbacks of IR interface. Again this is software cum hardware project. The software program is written in a computer (written in C++) and it generates a specific code and transmits it over 433.92 MHz carrier frequencies. This code…

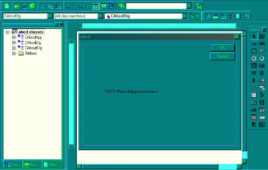

Stepper Motor Controller with VC++

This is second window based application built on the platform of VC++. This project tells you how to control a stepper motor using VC++. With the help of VC++ computer will control all the actions of bipolar stepper motor like varying speed (RPM), varying number of rotations, changing directions etc. 2-degree of motion control is provided…

Remote Unipolar Stepper Motor Controller with 89C51

This is the third and most amazing application of multichannel IR remote where 4 different channels of remote are utilized to control all the parameters of unipolar stepper motor. All three parameters of stepper motor RPM, direction & no. of revolutions can be changed from remote. 89C51 takes care of all the controlling actions. If you have…

Stepper Motor Angle Control using AVR Microcontroller

This project demonstrates how any device or object can be positioned to desired angle. The circuit presented here demonstrates how to position Stepper Motor at a specific Angle using AVR microcontroller. The desired Angle Position is entered by user and when He presses the button to rotate motor, the motor starts rotating and rotates till it reaches that angle. The angle can be entered in step of 15o between 0o to 360o. User can increment or decrement angle value in step of 15o and set the desire angle. Based on set angle motor rotates forward (CCW) or reverse (CW). Like if current motor angle is 60o and user enters 90o then motor rotates CCW and if user enters 30o motor rotates CW.