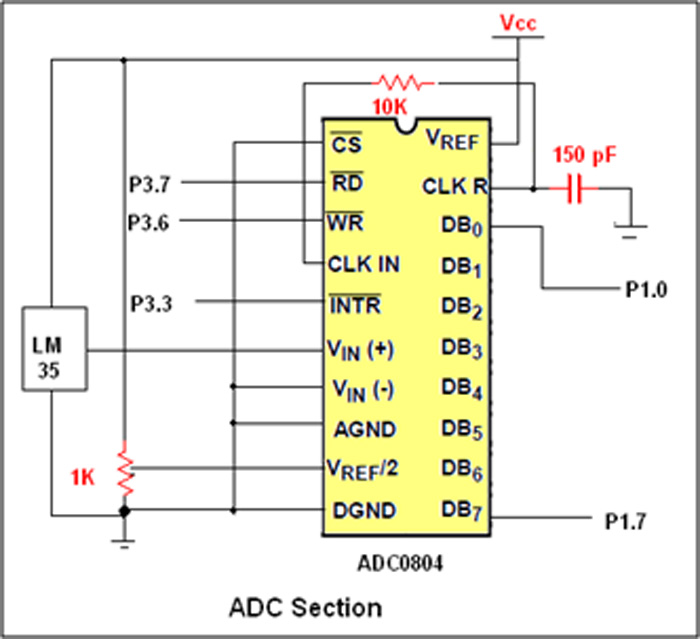

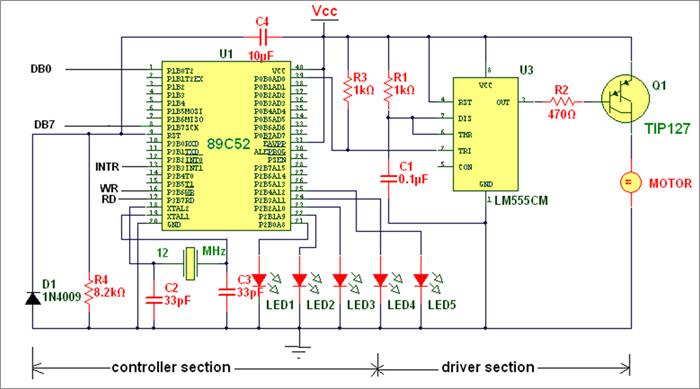

Obviously you might have seen so many temperature controller and indicator applications using different microcontrollers, micro-processors or other controlling devices. But this is the actual application of temperature controller that controls speed of DC fan as temperature varies. It is not a simple ON-OFF type controller that switches fan ON / OFF when temperature increases / decreases certain limit. But it is a type of controller that continuously varies speed of DC fan as temperature increases / decreases. That is a demo of actual industrial application.

Circuit

Controller and driver section

Software program

Video

Project Source Code

###

#include<reg51.h>

#include<string.h>

sbit wr = P3^6;

sbit rd = P3^7;

sbit op = P0^0;

sbit eoc = P3^3;

unsigned char data d;

unsigned int d1=3,d2=7;

void delay(int a)

{

int k;

TL0 = 0x26;

TH0 = 0xFC;

TR0 = 1;

for(k=0;k<a;k++)

{

while(TF0==0);

TF0 = 0;

TL0 = 0x26;

TH0 = 0xFC;

}

TR0 = 0;

}

void int1(void) interrupt 2

{

rd = 0;

d=P1;

rd=1;

if(d>=0x19 && d<=0x1E) {d1=3;d2=7;P2=0x01;}

else if(d>=0x1F && d<=0x24) {d1=5;d2=5;P2=0x03;}

else if(d>=0x25 && d<=0x2A) {d1=7;d2=3;P2=0x07;}

else if(d>=0x2B && d<=0x30) {d1=8;d2=2;P2=0x0F;}

else if(d>=0x31 && d<=0x37) {d1=9;d2=1;P2=0x1F;}

wr = 0;

wr = 1;

}

void main()

{

TMOD = 0x01;

P0=0x00;

P0=0x1F;

op=0;

P1=0xFF;

eoc=1;

IE=0x84;

wr = 0;

wr = 1;

while(1)

{

op=1;

delay(d1);

op=0;

delay(d2); }

}

###

Circuit Diagrams

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.