New Products that use Flex PCBs

Flexible printed circuit boards are at the forefront of the new wave of electronics found in healthcare, military, and consumer markets.Researchers are continuing to push the limits of possibilities for flexible PCBs, expecting the industry to grow five-fold in the next 10 years.

New materials, such as polyimide, allow a thinner, lighter product with the ability to move more freely.Conductive ink printing allows the elimination of connectors and cables, improving connectivity and assembly costs.The traditional process for manufacturing PCBs requires as many as 6 steps. New knowledge has shortened the process of manufacturing flexible PCBs to as little as 3 steps.

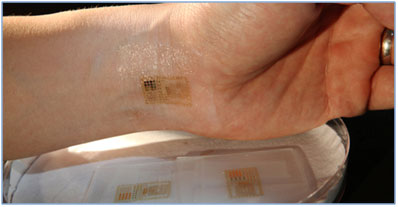

Smart Skin

Fig. 1: Representational Image of Smart Skin

The common doctor visit consists of signing in, waiting, visiting with a nurse and waiting some more before finallytalking with a doctor.Throughout each step data about the patient is gathered and processed. The process of finding pertinent data can be simplified by applying a new adhesive patch on to the surface of a patient’s skin called “smart skin.”Through the “smart skin” patch, informationisrelayed through transmitters or antennas.Details such as heart rate, temperature, glucose levels, ECG, and EKG readouts

will be available.Cables, tape, leads, and bulky equipment are eliminated! The patch is thin and lightweight, making itnearly undetectable.It can be adhered using water, similar to temporary tattoos.The material is designed to be ultra-flexible and move with the person’s skin.

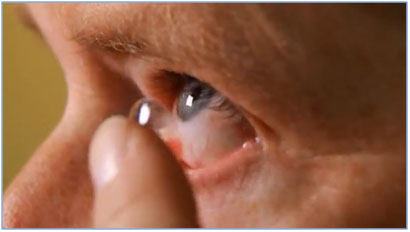

Glucose Monitoring Contact Lens

Fig. 2: Symbolic Image of Glucose Monitoring Contact Lens

The pains of monitoring a diabetic’s glucose levels can be cumbersome.A needle prickon the fingertip allows a small amount of blood to be dispensed for testing.The blood needs to be placed ona test strip which enters a glucometer machine, with this routine needing to be repeated as often as eight times a day.Flexible PCBs are on the verge of helping to create a contact lens that monitors glucose levels, eliminating painful finger pricks, hazardous medical supplies (such as testing strips and needles) and manual result tracking.

The contact lens is equippedwith a glucose sensor.A flexible PCB is placed on the lens with components that allow wireless transmission.The informationwill be streamed or transmitted to an outside location for interpretation and tracking.The use of flexible PCBs allows a very small and thin circuit that is undetectable.Previous PCBs would be too thick, stiff, and bulky for anything even close to this seamless application.

This video by Microsoft explains the glucose monitoring contact lenses further

Consumer Products

Wearable consumer devices like smartphones and data capturing bracelets are being released to the public at an increasing rate.Flexible PCBs will be utilized in Smart technology to allow a lightweight, thin option which can be wornas opposed to a bulky item that has to be carried. Some of the items are even powered using solar cells as opposed to battery power.

Consumers will not be the only ones to wear flexible PCB products.Actual materials will be wearing labels.The labels will benefit consumers using sensors and antennas.Radiation tags can be placed on products to monitor levels.Pharmacies can use labels to read and track temperatures on drugs that needtemperature control for stability.Foods can be fitted with labels that test for contaminates.

Power Sources

Power sources will need to adapt in order to keep flexible PCBs a viable option. The future holds the possibility of stretchable power sources.Most likely, new technology will apply carbon nanotube microfilm, polyurethane membranes and organic electrolytes.Another possibility is a bendable Li-ion battery.This would use cobalt oxide as cathode material and lithium for anode material.

The Future

Flexible PCBs are expanding the world of possibilities.Healthcare is considering Smart Surgical instruments.The possibility remains of a pacemaker that is more conducive to quality of life.Neural implants are being considered to control prosthetics.Biosensors, similar to the Smart Skin, will relay data to remote locations.Patients with neuromuscular disorders affecting their communication will be able to communicate and interface with a computer.Flexible PCBs will continue to improve access, delivery, comfort and convenience to health care patients.

About the Author

This article was written by Alex Danovich, President of San Francisco Circuits as a part of their PCB School program, educating engineers and customers on PCB fabrication and assembly. Visit their website for more circuit resources on ultrasonic cleaning, PCB equipment and more.

SFCircuits is a PCB manufacturingand assembly provider located in California, specializing in Flex PCBs and other high-tech circuits.

Filed Under: ARM., Articles, Tech Articles

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.