This is the most amazing and commercially viable project in which the web-cam attached to your computer will move in all four direction up-down and left-right with the help of your fingertips.

The software written in VC++ will control two different AC motors with the help of computer mouse. The forward and reverse motion of these motors will move web-cam up-down or left-right depending upon once choice. There are two modes to move camera in all four directions. 1) Auto and (2) manual. In auto mode the camera moves left-right-up-down in a user program sequence while in manual mode it will move depending upon user command.

General Description:-

There are three basic parts of project. (1) mechanical (2) hardware and (3) software.

Mechanical part is camera unit which consist of camera lens, two AC motors with given specifications and internal mechanism to rotate lens. The specifications of motor are

Motor type: – AC reversible motor

Max applied voltage: – 230 VAC

Max rated RPM: – 5 RPM @ 230 VAC

Hardware part is AC motor driving circuit attached to LPT port of PC that will switch the supply given to motor and move it in a proper way

Software part is the actual interface between user and camera that will generate various signals through LPT and rotate two AC motors.

Note:-mechanical part is ready-made and available in market so we shall not discuss about it in deep

Hardware & Software

Hardware Section: –

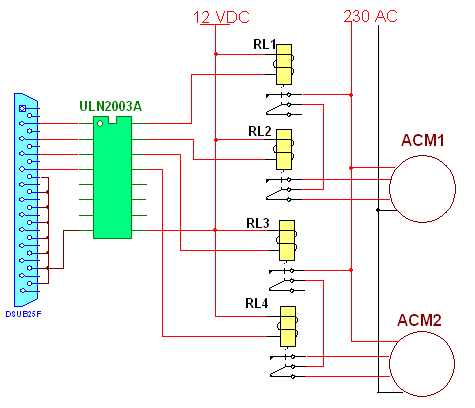

The circuit is designed to rotate both AC motors in either direction. For each motor we have two relays one for to turn ON or OFF the motor and second for changing direction. So four change over (C/O) relays are connected to LPT pins D0-D3 through current driver chip ULN2003A. All the relays are 12 VDC, 300 ohm (sugar cube type, PCB mount). One of the coil terminal of all the relays are shorted and connected to 12 V supply. The second terminal is connected to output of ULN chip. The relay contacts (C, NC, NO) are connected as shown in figure in Circuit Diagram Tab1.

Here relays RL1 and RL3 are to turn ON / OFF the motors and RL2 and RL4 are for direction change. The ACM1 is used to move camera left and right while ACM2 moves camera up and down. So by switching these relays the camera will move in all four directions. The table given below will give you the idea that how a software can move the camera using LPT port

|

Relay(s) |

Data pin(s) |

Camera movement |

Hex number |

|

RL1 |

D0 |

Left to right |

01h |

|

RL1 & RL2 |

D0-D1 |

Right to left |

03h |

|

RL3 |

D2 |

Bottom to top |

04h |

|

RL3 & RL4 |

D2-D3 |

Top to bottom |

0Ch |

Software section:-

As illustrated first there are two modes auto and manual, so in auto mode the software moves camera in pre programmed sequence and in manual mode the user (operator) can move the camera from keyboard or mouse. The application window look like this.

There are two group boxes, seven buttons and two check boxes. Here are there settings

|

Item |

Property |

Setting |

|

Group box 1 |

ID |

IDC_AUTO |

|

Group box 2 |

ID |

IDC_MAN |

|

Button 1 |

ID |

IDC_UP |

|

Caption |

UP |

|

|

Button 2 |

ID |

IDC_DWN |

|

Caption |

DOWN |

|

|

Button 3 |

ID |

IDC_LEFT |

|

Caption |

LEFT |

|

|

Button 4 |

ID |

IDC_RGHT |

|

Caption |

RIGHT |

|

|

Button 5 |

ID |

IDC_XIT |

|

Caption |

EXIT |

|

|

Button 6 |

ID |

IDC_ON |

|

Caption |

ON |

|

|

Button 7 |

ID |

IDC_OFF |

|

Caption |

OFF |

|

|

Check box 1 |

ID |

IDC_CHECK1 |

|

Caption |

Enable |

|

|

Check box 2 |

ID |

IDC_CHECK2 |

|

Caption |

Enable |

After completing design now we have to attach code with these buttons. We have two enable buttons here so only one of the mode will be enable at a time. As you enable one mode second will be disabled. In manual mode all the given four buttons will send the hex number given in above table to LPT port address that is 0378 so that the particular relay get energized and it will rotate the motor.

The automatic mode is somehow different. The movement of camera is preprogrammed. The camera moves 150 deg. Left to right and 150 deg. Top to bottom. Now as the motor is of 5 RPM means it rotates 1800 deg. In 60 sec. So in 1 sec motor rotates 30 deg. Thus to complete 150 deg it needs 5 sec.

Now the movement is divided in 6 steps

- Left to right means 5 sec (01h)

- Right to middle means 2.5 sec (03h)

- Middle to top again 2.5 sec (04h)

- Top to bottom. 5 sec (0Ch)

- Bottom to middle. 2.5 sec (04h)

- Middle to left again 2.5 sec (03h) and this cycle repeats

So for this we have used one counter that will count at an interval of every 0.5 sec. Total cycle time is 20 sec means the counter counts up to 40. The program assumes that when auto mode is enabled the cameras is at left most position

You may also like:

Circuit Diagrams

Filed Under: Circuit Design, Electronic Projects

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.