Despite all growth and development, the world is still suffering from issues like shattered iPhones, broken remotes, and cracked car bumpers. However, a simple solution to this was discovered by researchers working at the University of Illinois by creating a self-healing plastic that will become a practical reality sooner. There is no dearth of self-healing materials that have been into play from last so many centuries, but their usage and application were restricted till date. The team from Illinois claims that their product will be able to take care of cracks and fractures taking place even on the largest scales courtesy their biologically inspired vascular nature. The Chemistry professor here, Jeffery Moore, says, “ We have demonstrated repair of a nonliving, synthetic materials system in a way that is reminiscent of repair-by-regrowth as seen in some living systems.”

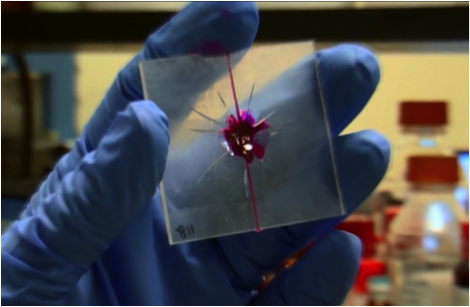

In order to achieve one such regrowth phenomenon, the new materials have been imbibed with “specially formulated fibers” that behave like capillaries that branch across the body of their host polymer. These are composed of two different lines that are completely parallel with each other, Every single capillary has “regenerative materials” that get mixed as soon as the damage is initiated. As and when it gets mixed, the binary regenerative cocktail releases a gel that moves across the crack or damaged parts and hardens the polymer to get it back to its original shape.

Lead researcher of this project, Scott White, says, “For the first time, we’ve shown that you can regenerate lost material in a structural polymer. That’s the kicker here. Prior to this work, if you cut off a piece of material, it’s gone. Now we’ve shown that the material can actually regrow.” The team says that the synthetic materials can start to make a gel and harden it immediately, this ensures better efficiency of damage repair and reduces wastage of any of these materials in any way.

Filed Under: News

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.