Now, scientists at the Department of Energy’s Argonne National Laboratory have identified a novel method to detail the formation of such material transformations at the atomic scale and in near real-time, an essential step that could aid in engineering stronger and better novel substances.

According to the scientists, they have, for the very first time, captured images of the preparation of structural issues in palladium when the metal is revealed to hydrogen. Such imaging potential will assist scientists validate models that expect the behaviour of substances and how they create defects. Defect engineering is the practice of intentionally creating issues within a substance in order to alter the substance’s properties. Such knowledge is central to engineering better, reliable and stronger materials for semiconductors, batteries, buildings, technological devices and numerous other tools and items.

“Defect engineering is based on the idea that you can gather something you already know the properties of and by placing in imperfections, engineer things with enhanced properties,” says Argonne Scholar Andrew Ulvestad, one of the lead authors of the study. “Such practice applies not just to metals but any substance that possesses a crystal structure, such as those found in solar battery and cells cathodes.”

Defect engineering is employed to optimize material design across a range of fields, but it is most popularly associated with the development of semiconductors. Semiconductor substances, such as silicon, are employed as electrical components; they create the foundation for most of the modern day electrical, comprising mobile phones and laptops.

In a procedure known as ‘doping’, manufacturer result in defects in such substances by placing impurities in order to manipulate their electronic properties for numerous technological uses. While manufacturers know they can alter the features of numerous substances to get the attributes they want, the procedures that govern such changes are not always precise.

To enhance the understanding of such procedures, Argonne scientists emphasized specifically on defects, forming on the nanoscale. Interfaces, defects and fluctuations at such highly small level can offer crucial insight into the functionalities of substances, like their electronic, thermal and mechanical properties, on a bigger scale.

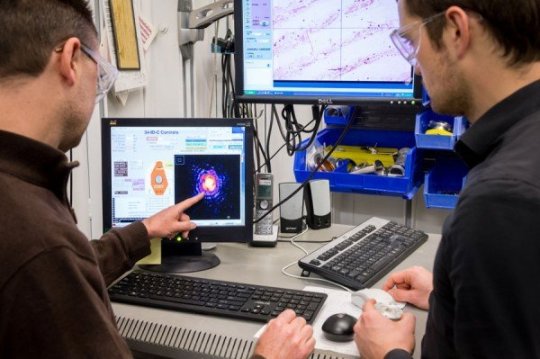

To gather the formation of defects, the Argonne group took a nanostructured sample of injected and palladium, or infused it with hydrogen at high level of pressure. At the same time, they revealed the sample to powerful X-rays at the Advanced Photon Source.

Approaches related to defect engineering are already being employed to study other systems, comprising battery cathode nanoparticles. But, the study conducted by Harder and Ulvestad is the first to gather the formation of issues as they are happening. “What we have done is to prepare a roadmap for other scientists. We have shown a method to model this system and range of systems that have similar dynamics,” says Ulvestad.

Filed Under: News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.