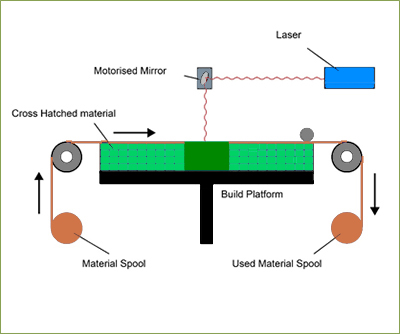

Sheet lamination is one of the seven recognized 3D Printing methods. The process uses sheets of building material which are cut through laser or knife and the sheets are joined one after the other either by using an adhesive or by wielding the laser cut sheets together to form the 3D object. The process is also called ultrasonic additive manufacturing (UAM) in case the building material used is metal sheets.The variation of the process in which paper is used for making the 3D models is known by the name – Laminated Object Manufacturing (LOM).

Sheet Lamination is a low temperature process and is used for making models for display. The process is quite useful for making visual models speedily at low cost. The process is however not suitable for making structural or functional models. That is why, even for prototyping, sheet lamination process has limited use. The process is usually used for making dummy models for demonstration purpose only.

The Sheet Lamination is definitely the fastest 3D printing process as the laser cutter has just to follow a computer controlled path during the formation of each layer. The process has easy handling and low costs per model. The limitation is that the strength and durability of the model created depends largely on the quality of adhesive (in case of LOM) or finish of the wielding (in case of UAM). The process despite being speedy one often require some post processing to give the model a final look and structure. Sheet lamination is a fusion type process and is deemed to have limited scope of evolution as same is assumed for other fusion type 3D printing processes.

The choice of material to use in sheet lamination process is limited to metal sheets of Stainless steel, Aluminium, Titanium and Copper, plastic sheets and A4 size papers.

The sheet lamination process was first introduced by Helisys, Inc. but it has already ceased the operations. The Helisys products are now developed and supplied by Cubic Technologies. Other companies providing sheet lamination services are Ireland based Mcor Technologies Ltd, Japan’s Kira, Inc. and Israel based Solido 3D. Currently, Cubic Technologies is providing SD300 LOM 3D printer at a price of $14,995.

A range of LOM printers are available from Mcor Technologies including MCOR ARKE, MCOR IRIS HD and Matrix 300+.

Filed Under: Tech Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.