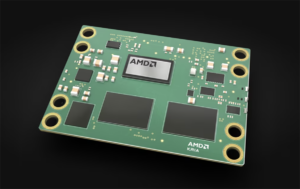

AMD recently announced the AMD Kria K24 System-on-Module (SOM) and its new KD240 Drives Starter Kit, which are the latest additions to the Kria portfolio of adaptive SOMs and developer kits.

AMD Kria K24 SOM offers power-efficient computing in a small form factor and targets cost-sensitive industrial and commercial edge applications. Advanced InFO (Integrated Fan-Out) packaging makes the K24 half the size of a credit card while using half the power of the larger, connector-compatible Kria K26 SOM.

AMD Kria K24 SOM offers power-efficient computing in a small form factor and targets cost-sensitive industrial and commercial edge applications. Advanced InFO (Integrated Fan-Out) packaging makes the K24 half the size of a credit card while using half the power of the larger, connector-compatible Kria K26 SOM.

The K24 SOM provides high determinism and low latency for powering electric drives and motor controllers used in compute-intensive digital signal processing (DSP) applications at the edge.

Key applications include electric motor systems, EV charging stations, robotics for factory automation, power generation, public transportation (such as elevators and trains), as well as surgical robotics and medical equipment (like MRI beds).

Coupled with the KD240 Drives Starter Kit, an out-of-the-box-ready motor control-based development platform, the products offer a seamless path to production deployment with the K24 SOM. Users can quickly be up and running, speeding time to market for motor control and DSP applications without requiring FPGA programming expertise.

“The AMD Kria K24 SOM and KD240 development platform build on the breakthrough design experience introduced by the Kria SOM portfolio, offering solutions for robotics, control, vision AI, and DSP applications,” said Hanneke Krekels, corporate VP, Core Vertical Markets, AMD. “System architects must meet growing demands for performance and power efficiency while keeping expenses down. The K24 SOM delivers high-performance-per-watt in a small form factor and houses the core components of an embedded processing system on a single production-ready board for a fast time to market.”

Many factories have hundreds of motors powering robotics that drive assembly lines and other equipment. It is estimated that around 70% of the total global electrical use by the industrial sector is tied to electric motors and motor-driven systems. As such, even a 1% improvement in the efficiency of a drive system can have a significant positive impact on operational expenses and the environment.

“The AMD Kria SOM portfolio has helped make robust hardware for robotics and industrial edge applications available to the masses and we’re excited to see the portfolio extended with the new K24 SOM and KD240 Starter Kit,” said Greg Needel, CEO of Rev Robotics. “With Kria SOMs we’re able to simplify development of even advanced control loop algorithms, adapt to changing software and hardware requirements, and build really cool things for both commercial and STEM educational customers.”

Simplified DSP development

The K24 SOM features a custom-built Zynq UltraScale+ MPSoC device and the supporting KD240 starter kit is a sub-$400 FPGA-based motor control kit. Enabling developers to begin at a more evolved point in the design cycle, the KD240 provides easy access for entry-level developers compared to other processor-based control kits.

The K24 SOM comes qualified for use in industrial environments with support for more design flows than any generation before it. That includes familiar design tools like Matlab Simulink and languages like Python with its extensive ecosystem support for the PYNQ framework. Ubuntu and Docker are also supported. Software developers can also use the AMD Vitis motor control libraries while maintaining support for traditional development flows.

With the launch of Kria K26 SOM, AMD introduced the first App Store for edge applications. By introducing the KD240 Starter Kit, AMD is now the first to offer pre-built motor control apps, allowing users to create power-efficient industrial solutions that are reliable, available, and with advanced security features.

The KD240 is supported by an optional Motor Accessory Pack (MACCP), with additional motor kits available in the future that can be purchased separately for an enhanced ramp-up experience for developers.

Scalable SOMs

Kria SOMs allow developers to skip the substantial design efforts around the selected silicon device and instead focus on providing differentiated, value-added features.

Connector compatibility enables easy migration between the K24 and K26 SOM without changing boards, allowing system architects to balance power, performance, size, and cost for energy-efficient systems.

K24 SOMs are offered in commercial and industrial versions, and are built for 10-year industrial lifecycles. In addition to support for expanded temperature ranges, the industrial-grade SOM includes ECC-protected LPDDR4 memory for high-reliability systems.

You may also like:

Filed Under: Components, Electric Vehicles, EV Engineering, FPGA, News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.