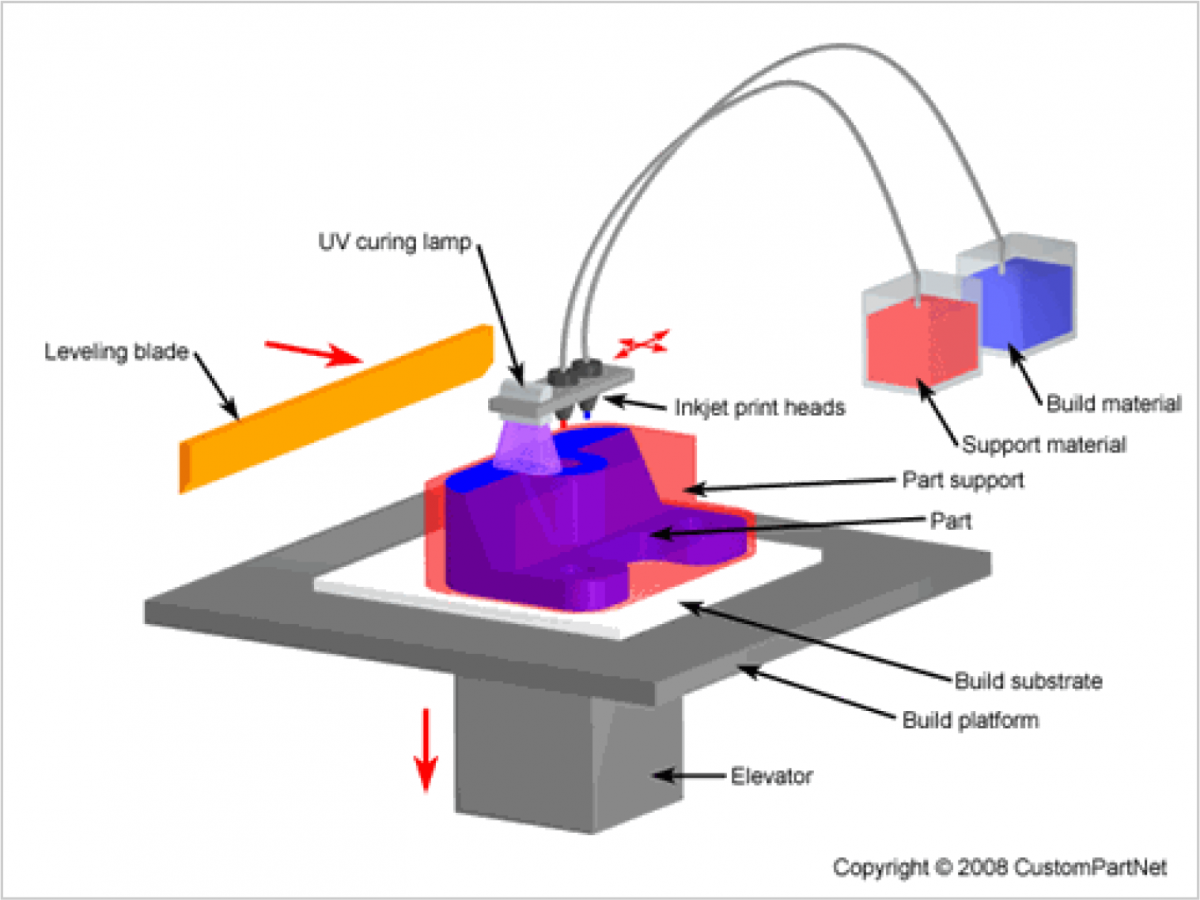

Material Jetting is one of the standard 3D printing technology that has scope and design pattern suitable for the desktop version of 3D printers as industrial 3D printers. The technology fabricates a 3D part just like an inkjet printer prints a two-dimensional image. The 3D model is built on a target surface to which droplets or continuous fluids of the building material are dropped layer by layer and each layer is then cured with ultraviolet radiation to get it solidified. The term “Drop on Demand” is used for referring the drop by dropwise fabrication of 3D model in the technology’s context.

A typical apparatus for material jetting 3D printing has printer head consisting of two nozzles and an UV source. One nozzle is used to jet the building material while another nozzle is used for jetting the support material. The support material is not the part of the model but is usually deposited along the building material to keep the model in fixed orientation while it is 3D printed. Both the building material and support material deposit on a platform layer by layer. The support structure is built from such material choices that they can be removed after finishing the fabrication of the model. So the printer head deposits a computer controlled sequence of building material as well as support material layer by layer while the UV source directs radiation towards the immediately deposited material droplet (either building or support material) to solidify it with the adjacent droplet. Once the model is finished, it is allowed to cool and hardened. Later on, the support structures are scratched off.

The main advantage of using material jetting process is its speed and high accuracy of the model creation. The high-level accuracy is obvious due to drop by drop deposition and immediate hardening. The process allows to incorporate different colors of material to a single part and multiple parts can be formed on the same platform at the same time. However, the process can be used to make 3D parts from plastics and waxes only. Thus the choice of material is limited with the Material Jetting Process. The commonly used polymers in material jetting are Polypropylene, Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polyamide (PA), Polycarbonate (PC), High Impact Polystyrene (HIPS), High-density polyethylene (HDPE) and Polymethyl methacrylate (PMMA).

Some example of material jetting 3D printers are Objet 30 Pro, Objet 24, Objet Eden 260V, Objet Eden 500V, Objet Eden 350/350 V, Objet 260 Connex, Objet 500 Connex, Objet 350 Connex and Objet 1000.

In the final article of this series, Sheet lamination Process for 3D printing will be discussed.

Filed Under: PIC Microcontroller., Tech Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.