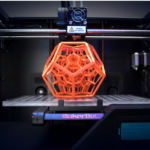

Previously, we discussed open-source 3D printable humanoid robot projects. Now, we’ll cover the top 3D printable robotic arms. A robotic arm is a pick-and-place robot typically used in manufacturing assembly lines. They’re also used for CNC, laser engraving, and 3D printing.

The robots are designed to repeat specific tasks with the highest accuracy and precision. Servos electronically control each robotic movement. The continuous movement of the arm is a result of the simultaneous operation of several servo motors.

The servo motors are critical, but the robotic arm’s mechanical parts are also essential — and can be 3D printed, even with a reasonably low-budget printer.

The exact mechanics of a robotic arm depends on the assembly’s size, dimensions, and structure. The placement and orientation of the servos are also important considerations.

There are several 3D printable robotic arm projects available. Not all, but many of them are open-source and available for free. Aside from a printer, what’s required is the downloaded STL files, 3D-print robotic parts, and the servos for assembly.

Here are a few to choose from, depending on your interest, time, budget, and 3D capabilities.

LittleArm V3 is the most straightforward 3D-printed robotic arm that can be built at home. Now available in its third version, LittleArm was created in 2016, with a second version released in 2017. The latest version of this project offers a new gripper, upgraded software, and advanced hardware designed to reduce the necessary components. Only four 3D-printed pieces are required to build this robot, with 21 parts and six screws. After the 3D parts are ready, it only takes 20 minutes to assemble the arm.

A USB or Bluetooth can control LittleArm. The software uses the same functions and routines that control most modern robots and is available for a desktop and Android (but not Mac OS X).

The hardware required to build the robotic arm includes Arduino NANO, a custom PCB (available from LittleArm V3), a Bluetooth module (if you want to control the arm from Bluetooth), four servos, a power adaptor, and the 3D printed parts. You can buy LittleArm a complete or sample kit from kickstarter.com.

EEZYbotARM MK3 is a 4 DOF robotic arm with a rotating base and a two-finger grip. The MK3 version is smaller in size, making the project more accessible. It offers a straightforward design with excellent instructions. For a larger, more sturdy arm, consider the MK2 version. The control for MK2 and MK3 are customizable and can be tweaked to emulate different movements. The robot can also be directly controlled with a computer, with a sequence or a loop of movements programmed to run from a pushbutton. The project is available at eezyrobots.it.

MeArm is a popular, open-source robotic arm project, available as a 4 DOF pick-and-place robot. It can be built using Arduino UNO or Raspberry Pi. The parts required to assemble the robot can be laser cut or 3D printed. Only four servos are required aside from the microcontroller board. The code to control the bot is available on Github, and users can play with the code to customize MeArm’s functions. MeArm can be controlled via Wi-Fi.

The instructions to build the robot with Arduino, Raspberry Pi, Micro:Bit, or WiFi are available at mearm.com. This is an excellent robotic arm project for beginners and intermediates.

Kauda is a 5 DOF robotic arm that comes with easy-to-follow instructions. It can be built using Arduino MEGA, two servo motors, and three stepper motors. Kauda is a low-cost DIY, 3D printable robot designed primarily for educational purposes with open-source parts and software.

The complete instructions to build Kauda are available at instructables.com. It requires 41 3D-printed pieces (nine of the parts are optional). The electronics required include Nema-17 stepper motors, MG996R Servos, a 6V extended gear DC motor with a shaft, and Arduino MEGA. The Arduino code and other resources for Kauda can be downloaded at diy-tech.com.

OWI Edge – this wireless robotic arm is only available as a kit on Amazon and owirobot.com. The project can be bought for just $43.95. It comes with a controller board, 3D-printed parts, servos, and accessories. The kit is shipped with a CD that contains software to control the project from a home computer. Although OWI Edge offers nothing to build from scratch, it’s a great starter project

UFactory uArm is a highly capable and durable robotic arm that can 3D print or laser engrave if equipped with the proper tool head. uArm is a 4 DOF robotic arm with a precision of 0.2 mm. It can be used for commercial applications such as drawing, virtual reality, food service, or coffee machines. In industrial applications, it can be used for dispensing, packaging, pick-and-place, kitting, part insertion, screw driving, finishing, and test and measurement.

This versatile robotic arm can be controlled and programmed without coding by using its own software, UFACTORY uArm Studio. Python SDK is available for programmers. The uArm kit can be purchased for around $800.

PincherX 100 is a 4 DOF robotic arm with a precision of 5mm. It has a working payload of 50g, a span of 600 mm, and a reach of 300 mm. All parts in the kit are 3D printed using ABS. The PicherX 100 is ideal for vision-based pick-n-place artificial intelligence and machine learning. It was designed for educational purposes and can be programmed using MATLAB, ROS, Python, MoveIt, GAZEBO, and IRROS.

The PicherX package includes an optional joystick and an Intel D415 RealSense Depth camera. Several open-source demos for PicherX 100 are available online. Based on the ARM Cortex M3 controller, the robot uses five XL430-W250-T Servos and a parallel gripper. You can order PicherX 100 for about $650 from trossenrobotics.com.

Zortrax Robotic Arm is a 5 DOF pick-and-place robot project that can be downloaded at zortrax.com (the assembly guide is available at this link). What’s interesting about this robotic arm is that all its axes are powered — unlike other robotic arm projects, it requires no manual adjustment. All the parts used to build the robot are 3D printable.

Zortrax offers a maximum payload of 100 grams. By default, the robot has a mounted grasper, which can be replaced with an electromagnet, sucker, screwdriver, or drill. The tool head is interchangeable and can be deployed for different applications.

BCN3D MOVEO is a low-cost 5 DOF fully open-source robotic arm project. The STL files for building the robot can be downloaded from GitHub. All the parts can be printed using an additive-manufacturing technique. The robot is controlled by Arduino. The manual for assembling the robot is available in English and Spanish. The project is also available at thingiverse.com.

Thor is a 6 DOF fully open-source robotic arm developed by Hackaday, the makers of AngelLM, Dan Royer, and dannyvandenheuvel. Thor uses the same configuration (yaw-roll-roll-yaw-roll-yaw) typically used by industrial manipulators. It was designed for educational purposes, and all its parts can be 3D printed. About 625 mm tall, this robotic arm offers a payload of up to 750 grams.

Thor uses Arduino MEGA as a microcontroller. Its accuracy is high, thanks to seven stepper motors, controller by Pololu A4988 stepper driver shield. By using stepper motors instead of servos, the arm can rotate more than 360 degrees. Two of the DOFs use relatively small stepper motors. The project can be downloaded from thor.com.

Haddington Dynamics Robotic Arm’s ‘Dexter’ is a 3D printable robot with a price tag (starting at $11,000). Dexter has a reach of 770 mm and offers a maximum payload of 3 Kg, which is decent for a 3D printable robot. It requires only 70 3D-printed parts that provide an impressive, industrial-level 7 DOF robotic arm. Learn more about Dexter at hdrobotics.com.

Arduino Robot Arm, from How to Mechatronics, is an ideal choice for those interested in building a robotic arm from scratch. This is a 5 DOF robotic arm that’s wireless controlled through a customized mobile app. The project requires an Arduino board, three MG996R servos, three SG98 Micro servos, an HC-05 Bluetooth module, and a 5V DC power source. All the parts required to build the robot can be 3D printed.

This robotic arm can also be built using Arduino UNO. The STL files, Arduino code, and mobile app for the project are available for free at howtomechatronic.com. Interestingly, the Android app for the project was built using MIT App Inventor. The sliders in the app move the servos at the joints of the robotic arm. These movements can be saved and replayed in the app.

Instructables 3D Printed Robot Arm is available to build with Arduino at Instructables (the Arduino sketch for the robot is available at the same link). The project uses Arduino UNO, four standard servos, two micro servos, eight push buttons, an LED, and resistors. The parts for the robot can be printed using PLA filament with an Afinia 3D printer. They can be printed using any budget 3D printer. The result is a 4 DOF robot controlled with push buttons.

There are several 3D printable robotic arm projects online. Several are free and open-source; others are available as kits. All of these projects are based on 3D-printed parts, which is changing the accessibility of robotic projects.

You may also like:

Filed Under: Robotics, Tech Articles

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.