Yuan Young, an assistant professor who has been working in the materials science and engineering department at the Columbia Engineering recently reported successful development of a technology that can be used to enhance the energy density of Lithium-ion (Li-ion) batteries. For this purpose, he built a trilayer structure that is stable in open air increasing the endurance of battery and bringing down the overall costs. This thing may improve the energy density of lithium-ion batteries by 10-30 percent.

Yang says,”When lithium batteries are charged the first time, they lose anywhere from 5-20% energy in that first cycle. Through our design, we’ve been able to gain back this loss, and we think our method has great potential to increase the operation time of batteries for portable electronics and electrical vehicles.” During the first stage of charging of the lithium battery post manufacturing, a part of liquid electrolyte is turned to slid and then coated in negative battery electrode. The process usually takes place before the batteries are shipped to end-users. It is an irreversible process that brings down the energy capacity of the battery.

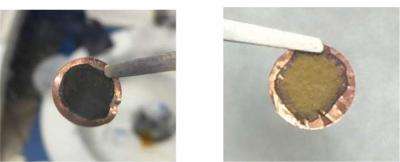

It is approx. 10 percent of the state-of-the-art negative electrodes, however, the same figure is expected to rise up to 20-30 percent in the next generation negative electrodes with better capacity. The initial loss of energy in higher quantities helps achieving full cell capacity and affects the energy density and cycling of the nanostructured electrodes. The customary approach to compensate for this loss is to place specific lithium-rich materials inside electrodes. But the biggest challenge these materials are unstable in open air. Production of batteries in dry air is a costlier process. Yang developed an innovative trilayer electrode structure that can make lithiated battery anodes in ambient air. In these electrodes, the lithium has been protected with a coat of polymer called PMMA. It keeps the lithium from reacting with moisture and air. The PMMA layer is then dissolved in battery electrolyte exposing the lithium to electrode materials. Yang explains, “This way we were able to avoid any contact with air between unstable lithium and a lithiated electrode. So the trilayer-structured electrode can be operated in ambient air. This could be an attractive advance towards mass production of lithiated battery electrodes.”

Filed Under: News

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.