Industrial robots are designed for use in industrial automation. They’re programmable machines that are specifically used to automate production-related tasks.

Typically, several robots are installed in an assembly line, each responsible for a specific objective. For example, some pick and place workpieces, some interact with different equipment (such as a lathe or milling machine), and others perform assembly work. They can also be reprogrammed to perform different types of applications.

A robot is a system built from several sub-systems. These sub-systems interact with one another and the workspace (such as an assembly line) to perform specific tasks.

Although industrial and service robots might perform different tasks, they share components and a common structure. In this article, we’ll learn about the components of an industrial robot or a robotic arm.

Components

There are five main components of a robotic arm.

1. Manipulator arm

2. End-effector

3. Actuators and transmission

4. Controller

5. Sensors

The robot/robotic arm is typically mounted on a fixed or mobile base.

The manipulator arm

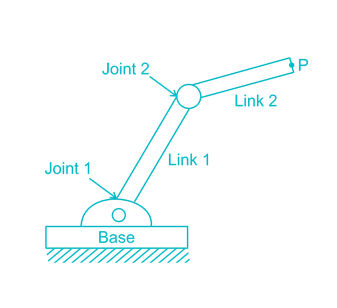

The manipulator arm is a programmable mechanical arm that functions similarly to a human arm. Its purpose is to move as required, providing reach in the workspace. It works as part of a complex robot or carries out independent tasks. Essentially, it’s a movable chain of successively coupled segments or links.

The segments are called cross-slides, as they can move over one another in a workspace. One end of the manipulator remains fixed to the ground or base, and the other remains free to hold the end-effector.

The manipulator arm is designed with a specific coordinate system, with several designs available. The simplest is a two or three-axis arm. The axis or degree of freedom refers to the independent movement of the segment or link. The point where two segments or links are coupled is called a joint. The segments are connected to one another by some lower pair connector.

Here are the types of lower-pair connectors or joints:

1. Revolute joint (R): has one degree of freedom (DOF), allowing relative rotational motion of the output link with the rotation axis perpendicular to the input and output link axis.

2. Prismatic joint (P): has one DOF, allowing a translational sliding motion between the input and output link. The axes of both links are parallel.

3. Helical joint (H): has one DOF, allowing rotational motion of the output link while translating about a screw axis perpendicular to the input link’s axis.

4. Cylindrical joint (C): has two DOFs — the first is the rotation of the output link, with an axis of rotation perpendicular to the axis of the input link. The second degree of freedom is the translational sliding motion of the output link along the axis perpendicular to the input link’s axis.

5. Universal joint (S): has two DOFs — the first is the rotation of the output link about the axis perpendicular to the input link’s axis. The second is the rotation of the input link about the axis perpendicular to the output link’s axis.

6. Spherical joint(T): has three DOFs — the first is the rotational motion of the output link about its own axis. The other two include the translational motion of the output link about the axes perpendicular to the input link’s axis.

Industrial robots are primarily designed in a body-wrist configuration. In a 6 DOF robotic arm, three links constitute the body placing the end-effector at the desired location in the workspace, and three links form the wrist of the manipulator putting the end-effector in the desired orientation.

Revolute and prismatic joints connect most links in the manipulator arm.

The end-effector

The end-effector is the gripper or arm tool mounted to the wrist of the manipulator arm. Depending upon the robot’s or robotic application’s task, a specific end-effector is attached to the wrist. For instance, there are different end-effectors for tasks related to material handling and material processing.

There can also be different end-effectors for the same task. For example, gripping can be done in several ways, such as mechanical clamping, magnetic gripping, or suction gripping. Each method uses a different type of end-effector.

Actuators and transmission

The actuators or drives are required to move the links about joints. The movement happens while carrying a desired payload by the robot. The payload could be an arm tool or a workpiece.

There are three types of actuators or drives used to build industrial robots.

1. Pneumatic drives: These actuators use compressed air to move the link about the joint. The motion could be translational or rotational. The pneumatic drives are typically used for linear or translational movements. They’re simple in construction, cost-effective, fast, and reliable. However, the drives are only suitable for small and light payloads, as there can sometimes be delayed movement and reduced repeatability.

2. Hydraulic drives: These drives use oil to move the link about the joint. The oil is pumped from a tank to the hydraulic actuator through a control valve. Both linear and rotational motion can be driven through these actuators. The hydraulic drives can move heavy payloads and are easy to maintain. They’re costly and are not always as accurate as other types of drives.

3. Electric drives: These are the electrical motors used to move the link about the joint. There are many different types of electrical motors, including brushless DC, stepper, DC servo, and reversible AC servo motors. The one used is based on the desired motion of the link and the required control and repeatability. The electrical motors are highly accurate, reliable, and can handle many payloads. The motors come with various price tags, depending on the features and given application.

Typically, transmission elements are required between the link and the drive. The actuator’s or drive’s output might exhibit different kinematics from the desired motion. For example, a DC motor produces rotational motion that must be converted to translational movement of the link. The actuator’s output might be unsuitable for applying to the link directly.

For example, a motor might have a high RPM output, but its RPM must be reduced or converted to the equivalent torque. Another case where transmission is required between the drive and the link is when the actuator is too big to fit along the link. In such cases, with a proper transmission, the drive is placed at a suitable location around the link, and any conflict between the movement of interconnected links is resolved.

The controller

A controller is a computing unit that controls the motion of links in a programmable manner. The controller could be microcontrollers, specialized controllers, or computers.

The controller takes feedback from sensors, controlling the outputs of the actuators so the robot moves sequentially to accomplish its task. The sensors and actuators are interfaced with the controller through hardware interfaces. The controllers can also have a user interface for reprogramming or human inputs.

Sensors

The sensors interact with the robot’s workspace and assess the movement and orientation of the manipulator arm and end-effector. The controller then considers further actions.

Two types of sensors are used in building industrial robots, tactile and non-tactile. Tactile sensors make physical contact for sensing, generating analog or digital signals in proportion to the measure of the desired physical quantity.

Tactile sensors include force, torque, pressure, touch, and position sensors. The non-tactile sensors make no physical contact for sensing but use a magnetic field, radio waves, or ultrasonic sound waves. Non-tactile sensors include proximity, imaging, range imaging, and optical sensors.

You may also like:

Filed Under: Robotics, Tech Articles

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.