In any industrial process there may be one or more physical quantities are to be measured simultaneously. In such cases it is required to take reading of their values at regular interval and for that a person has to seat there and monitor it continuously. If there are so many such processes then they require more man power. This is really wastage of human power. Also the premises where the actual process runs may be hazardous or may be uncomfortable for mankind. In such cases it is viable to monitor all these physical quantities from central control room where hardly two or three persons can easily monitor all the values and take readings.

For this purpose it is required to send these values from process place to central control room. It is very easy to send these values using pair of wires and connections. But in that case there will be a complex network of lots of wires that may lead to chaos. Instead of that isn’t it interesting to send these values wirelessly?

So the application given here illustrates one such concept. All the physical quantities that are measured at one place, their values are sent wirelessly to a remote location. The values are sent at regular intervals. Their values are displayed at both ends without change. Along with there are indication for changing in values. So this system is also useful in taking some decisions. So let us see how the concept is utilized…….

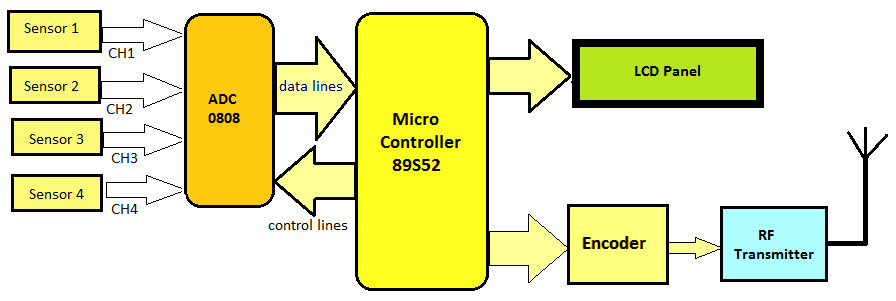

Complete system is divided in two sections. (1) Transmitter section &,(2) receiver section. So let us see block diagram of both sections

Transmitter & receiver section

Transmitter section: –

The given figure shows major building blocks wireless data transmitter section. It performs so many tasks like

- Take readings of all sensors one by one at predefined time interval

- Displays their digital values on LCD

- It transmits these digital values through encoder and RF transmitter

Sensors: – All these sensors are different transducers that convert different physical quantities like temperature, pressure, flow, level etc in to electrical quantity (voltage or current). They produce equivalent voltage (or current) as the physical quantity changes. Sensors are mounted inside the process from where the physical quantity is to be measured

ADC0808: – The ADC is required to convert the analog signals coming from sensors into digital. ADC 0808 has built in multiplexer so it has 8 different input channels from which it can take 8 analog inputs (one by one) and convert them into digital

Micro-controller: – It performs following tasks

- Selects different input channel of ADC and receives digital input from it

- Displays digital values of all physical quantities on LCD

- Transmits these digital values through encoder and RF transmitter one by one

LCD Panel: – It is used to display the digital values of all four physical quantities

Encoder: – It encodes the digital value given by micro controller and gives it to transmitter

RF Transmitter: – It transmits the encoded data using RF carrier frequency. Its ASK base transmitter operates at frequencies like 333MHz, 434MHz etc.

Receiver section: –

Receiver section just receives transmitted values and displays it on LCD. It shows same values as they were displayed on transmitter side.

RF receiver: – It receives carrier signal and extracts data from it. It is ASK based receiver and detects carrier frequency of 333 MHz or 434 MHz etc

Decoder: – It decodes the encoded data and gives to micro-controller

Micro-controller: – It first receives digital values from decoder and then displays all four simultaneously on LCD panel. Also it indicates various events on indicators like data received, receiving data etc

LCD Panel: –Its function remains same as transmitted side. It shows the digital values of all four physical quantities

Indicators: – Indicates various events like currently receiving data, data received, and values changed from previous value etc.

Filed Under: Electronic Projects

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.