‘The world is getting warmer day by day.’ This sentence has started to crop up every now and then in our day to day lives. But seldom do we wonder what it means. What is warmer? How warm is warm? Is it hotter than hot, or just hotter than cold? To our human senses, temperature is only a subjective evaluation. For an objective and reproducible measurement, we need to quantify the temperature values, and to do that, a suitable measurement device is required.

Fig. 1: A Representational Image of Temperature Sensors

This is achieved through the use of temperature sensors.

Temperature and its Measurement

Simply speaking, temperature is the degree of hotness of the body which is a measure of the heat content in the body. The problem to quantify the heat content of the body on a scale did not arise until the invention of the Steam Engine. The curiosity of scientists to understand the behavior of water at different levels of heat contents gave rise to a formal and better laid out study. One of the first references for ‘temperature’ dates back to 1760, when Joseph Black declared that applying the same heat to different materials resulted in different temperatures. Years of rigorous scientific study led to many theories ranging from the simple ‘Caloric’ concept, which treated heat as a material substance which is exchanged among materials, to Carnot’s description of heat as a form of energy (which laid the foundation of the first law of thermodynamics). However, none of them satisfactorily explained the concept of temperature. It was Maxwell’s theory which offered good reasoning into it. He defined temperature of a body as is its thermal property which provides information about the energy content of the system. It is the measure of the average kinetic energy (energy by virtue of motion) of the molecules of the substance and signifies a heat potential due to which heat flows from higher temperature to lower temperature.

The word ‘temperature’ itself is said to be derived of the Latin word ‘tempera’ meaning ‘moderate or soften’. Moving along Maxwell’s line of thought, the velocity of molecules should be the basis of selecting the value of temperature, with absolute heatlessness being a state where the molecules are totally static. But, this measurement is not possible practically, and hence, other manifestations of the effect of heat are utilized to measure temperature, for example, the geometric expansion of materials. A brief history of temperature sensors with major milestones is shown in the figure below:

Fig. 2: A Table Representing Brief History of Temperature Sensors with Major Milestones

Types: Contact Temperature Sensors

Types of Temperature Sensors:

There are mainly two major classes of temperature sensors based on the sensing distance:

1. Contact Temperature Sensing: The sensor is brought into physical contact with the object to be monitored. This method can be used with solids, liquids and gases. The sensors used for measurement can vary from capillary bulb thermometers and bi-metal sensors to sensors that use varying voltage signals or resistance values.

Expansion Thermometers: These sensors use Bi-metallic strips which have different expansion rates at a particular temperature. Thus, this difference of expansion can be translated into temperature change using a mechanical pointer. Though not very accurate, these devices offer the advantage of being portable. Low cost applications like time compensators in mechanical clocks, thermostats where a higher temperature may open the contact as in heating control or may close it like in refrigerators make use of bimetallic strips to open and close mechanical switches which in turn control electrical switches like circuit breakers.

Filled System Thermometers: These devices are filled with some substitute which expands or contracts due to temperature change. They may be filled with mercury. However, as it is considered to be an environmental hazard, organic liquid types may be used instead. These do not require any electric power to operate and are stable even after repeated use. However, they do not provide any kind of reading storage solution and also cannot make point measurements. These find use in medical industry to measure body temperatures.

Voltage Signal based Sensors: Thermocouples are the main sensors of this category. The underlying principle is the Seebeck effect. When two different metals or alloys are placed together so as to form two junctions, a voltage is induced across the junctions when there is a difference of temperatures between the junctions. These sensors are capable of detecting very high temperatures (as high as 1700o), have a very simplistic design which makes them quite robust to shock and vibration and can have almost immediate response to temperature changes. They however provide localized temperature readings and need a cold junction compensation to maintain the temperature gradient. Also, they are highly non-linear devices when compared to other sensors and require extremely good algorithms on the part of the conditioning electronics and processors to compensate for the non-linearity. Thermocouples find application in extremely high temperature sensing applications, chemical reaction monitoring, metal cutting, gas chromatography, sensing temperatures inside internal combustion engines etc. owing to their wide temperature range and ruggedness; however, if high accuracy and linearity are desired, other temperature sensors must be used. Simple implementation ideas can be like the one in the following:

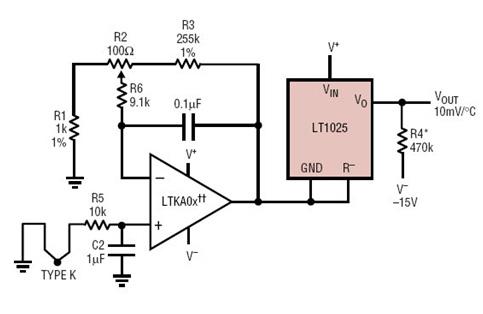

Fig. 3: A Figure Illustrating Architecture of Voltage Signal based Sensors

Resistance Values based Sensors: The resistance of metals and semiconductors offered to the flow of current through them changes with temperature. This change can be monitored and mapped to various temperature values on a scale. Further, on increasing the temperature, the value of resistance may increase or decrease. Substances with a positive temperature coefficient like most metals undergo a positive change of resistance with increasing temperature, while resistance of most semiconductors decreases with increasing temperature owing to their negative temperature coefficients. Based on the temperature coefficients, the Resistance Temperature Detectors (RTD) can be further divided into two types:

· Resistance Wire RTD: Mainly built with materials with positive resistance coefficient materials like platinum, RTDs are resistive elements which exhibit predictable change in resistance with temperature. The change of Resistance with temperature is given by the relation:

Fig. 4: An Equation Representing Change of Resistance with Temperature

Here, Rt and Ro are the resistances of the material at temperatures t and to oC and ? is the Average temperature Coefficient.

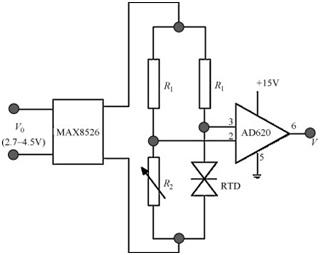

These devices may be in the forms of Thin Film Resistors or Wire-wounded Resistors. They offer a very wide linear range of temperature measurement (-200 to 650oC) and are very stable with minimal drift even with repeated operation year after year. A platinum resistance RTD has been serving as the primary interpolation instrument by the National Bureau of Standards. The signal output is quite large as compared to thermocouples, and can use ordinary copper wires for extension. Also, these can be spread over a large area. Such sensors may be mounted on one arm of a balanced wheat stone bridge circuit as shown in the figure below and the entire circuit be used to calculate and also control actuators for maintenance of temperature using feedback. They provide the desired linear range of operation where thermocouples fall short. RTDs find use in applications like cold junction compensation, calibration purposes, in a wheat stone bridge circuit and process control. The linearity simplifies the implementation of signal conditioning circuitry and makes RTDs suitable for high precision applications. RTDs measure absolute temperature in contrast with the thermocouples, and hence, might not be suitable for maintaining uniform temperature throughout the surface like the thermocouples are used.

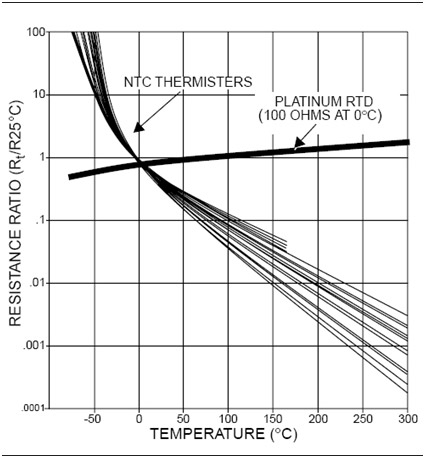

Fig. 5: A Figure Representing Architecture of RTD

·Thermistors: Semiconductors offer a variety of phenomenon and form the very basis of electronics. Both Positive (PTC) and Negative Temperature Coefficient (NTC) semiconductors are present and sensors based on them are differentiated as cold-wire PTC-thermistors and hot-wire NTC-thermistors. For PTC-Thermistors, Ferroelectricity is the predominant phenomenon causing the positive coefficient in a short range of temperature. The short temperature range of operation for these materials makes them suitable for use as temperature limiting switches. They have been used successfully in CRT monitors as timers in degaussing coils. They can be used as replacements for fuses in the form of current limiting devices. If the current increases, more heat is generated which heats up the thermistors. This increases the resistance which reduces the current and voltage available to the device thus protecting it from increased currents. For NTC-Thermistors, the relation between resistance and temperature is negative and exponential which is very repeatable. In the range of use, this exponential curve can be seen as a fairly linear plot and can even provide more sensitivity than RTDs which makes them more attractive in terms of accuracy in measurements.

Fig. 6: A Plot of Exponential Curve Offering more Sensitivity than RTDs

Owing to their low costs, they find ample use in automotive and consumer products industries like coolant and oil temperature monitors, incubator temperature maintenance, low temperature thermometers, modern digital thermostats, battery pack temperature monitors etc. A more recent application where NTC thermistors have been used is 3D printing, where thermistors are used to maintain a constant temperature at the hot end of 3D printers for the proper melting of pplastic filaments.

Integrated Silicon Temperature Sensors: Besides all these classifications, integrated circuits have been designed to provide ease of use while measuring temperatures in the desired scale. For example, the LM35 IC from Texas Instruments is a precision temperature sensor IC that offers reading directly on the Celsius scale and LM34 is another one offering readings on the Fahrenheit scale. These ICs provide Voltage readings which are directly proportional to a certain multiplier of temperature and hence can be directly read off a multimeter, or fed directly into an ADC for further processing. They provide easy integration and interfacing with other elements of the circuit. Many semiconductor companies like Analog Devices, Microchip, Smartek, ZMD and STMicroelectronics are into temperature sensors design and even provide signal processing circuitry and digital I/O interfaces for microcontrollers. These temperature sensors find widespread use in consumer products like personal computers, office electronics equipment, cellular phones, HVACs and battery management solutions.

Apart from these major principles of temperature measurement, other methods have also been developed. Some of them are, oscillating quartz temperature sensors, thermal noise thermometers, fiber optic thermometers and temperature measurement systems.

Fig. 7: A Figure Representing Integrated Silicon Temperature Sensors

Non-Contacting Temperature Sensors

2. Non-Contacting Temperature Measurement: These sensors make temperature measurements without physically contacting the object to be monitored. The most predominant method in this class of measuring sensors is Pyrometry which is an Infrared Measurement Technology.

Fig. 8: A Figure Illustrating Non-Contacting Temperature Sensors

Pyrometry: It is the process of interception and measurement of thermal radiation with a non-contacting device. The radiations emanating from the body are focused on to a radiation receiver using a lens as shown in figure above. The receiver can be any sensitive device like thermocouple, photoresistor, photodiode etc. The transducer action generates an electrical signal proportional to the amount of radiation which can be used to measure temperature. Different types of pyrometers are used, a few of them being total radiation pyrometer, distribution pyrometer, spectral pyrometer, disappearing filament pyrometer etc. These devices seldom replace contact sensors as they give the values of surface temperatures only.

Thermal Imaging Cameras: Though similar in principle to pyrometers, these devices produce a thermal picture of the object. These are mainly used in monitoring and control of machinery where localized heating can hamper normal operation.

Acoustic Measurements: Such devices are based on the principle of variation of dispersion velocity of sound in various materials with temperature.

Absolute temperature = K v2

Here v is velocity of sound. Further, acoustic measurements may employ quartz resonators or non-resonant methods like the Pulse-Echo principle of distance ranging. They find use inside furnaces like incinerators.

Selection Criteria of Sensors

Selection Criteria of Temperature Sensors

None of the temperature sensing devices are versatile enough to be used everywhere. If the thermocouples are known for their wide temperature range of operation, RTDs are unrivalled in the linearity range and thermistors are very accurate while the silicon sensors are easy to integrate in circuits. The use of a particular temperature sensor in some applications is governed by a number of parameters, the most important being temperature itself. The temperature range for the application, the rate at which the temperature may change, etc. help decide the type of design. For example, for sensors with high operating temperatures, special connection leads would be needed, while for sensors which have to deal with temperature shocks, wire-wound type of construction is preferred.

The stability and accuracy of the sensor at the prescribed operating conditions is another major factor to weigh while choosing design. Sensitivity of the device to measure small changes and how prone it is to self heating, determines the reliability of the device and its performance. The response time of the sensor is often governed by the size of the sensor. For example, the small dimensions of a film type resistor based sensor result in minimal associated heat capacity and hence, short response times (0.1 s in water and 3 to 6s in air). In the same application area, wire type resistor would respond in 0.2 to 0.5s in water and 4 to 25s in air. To aid you in choosing the right temperature sensor for your application, a comparison table of the 4 popular sensors is drawn below for easy reference.

|

|

Thermocouple

|

RTD

|

Thermistor

|

Integrated SIlicon

|

|

Temperature Range

|

-270 – 1800°C

|

-250 – 900°C

|

-100 – 450°C

|

-55 – 150°C

|

|

Accuracy

|

±0.5°C

|

±0.01°C

|

±0.1°C

|

±1°C

|

|

Linearity (Minimum order of polynomial, lesser the better)

|

4th order polynomial

|

2nd order polynomial

|

3rd order polynomial

|

Linearization not required. Within ±1°C

|

|

Sensitivity

|

? 10µV/°C

|

0.00385 ?/?/°C (Pt)

|

Several ?/ ?/°C

|

-2mV/°C

|

|

Ruggedness

|

Larger the gauge of wire, more is the ruggedness

|

Quite susceptible to breakage due to vibration

|

Hermetic thermistors housed in glass, not affected by shock or vibration

|

As rugged as an IC in plastic package like a DIP.

|

|

Responsiveness (test conditions)

|

Tres<1s

|

1s<Tres<10s

|

1s<Tres<5s

|

4s<Tres<60s

|

|

External Excitation Required

|

None

|

Current Source

|

Voltage Source

|

Supply Voltage

|

|

Output

|

Voltage

|

Resistance

|

Resistance

|

Digital/Current/Voltage

|

|

Cost

|

$1 to $50

|

$25 to $1000

|

$2 to $10

|

$1 to $10

|

Apart from these considerations, the choice of contact or non-contact sensors is subject to various other environmental conditions. While contact sensors may provide economical measurements and are quite accurate, the need physical contact, which may lead to contamination, wear and tear and heat sinking which alters the temperature to be measured. On the other hand, non-contact sensing offers faster response and monitoring from a remote location, but cannot measure gas temperatures and has ambient temperature restrictions which may affect the readings.

Almost everything in this world and universe hangs in place with a delicate balance. Life on earth was founded because the temperature was just right. Our body’s temperature needs to be regulated, or else the enzymes might malfunction. The temperature of the oceans gets a little higher, the Carbon Dioxide dissolved in it would get back into the atmosphere, causing more warming. Air Conditioning works because we can actually measure temperature and take corrective action. Electronic circuits perform optimally in a specific range of temperature. Though temperature sensors might not be able to ensure taste, but can definitely ensure that your meal is cooked just fine, and the wine tastes just exquisite. No wonder temperature is so important that it has been defined as one of the fundamental physical quantities of science. Hence, the importance of temperature sensors cannot be undermined.

Filed Under: Articles, Sensors, Tutorials

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.