An electric bike, or e-bike, is a popular, eco-friendly option for daily commutes. These bicycles are equipped with an electric motor to assist users in pedaling. E-bikes have next-to-no running costs, requiring little maintenance. They also let riders avoid gasoline costs, vehicle traffic congestion, and parking fees.

Most users buy assembled models, but it’s also possible to assemble an electric bike for a customized ride. In this article, we’ll cover what’s required to build your own e-bike.

Components

Building an e-bike allows you to customize the bike to suit your preferences. The following parts are essential to bring this two-wheeled ride to life.

Mechanical components:

- Bicycle frame

- Wheels

- Brakes

- Drivetrain

Electrical components:

- Electric motor

- Battery

- Motor controller

- Throttle or Pedal Assist System (PAS)

- Wiring and connectors

- Charger

Additional components:

- PAS sensor

- Display/Control panel

- Lights

- Fenders

Optional components:

- Suspension

- Cargo rack

Bicycle frame

First, you’ll need a bicycle frame, which is the main structure of the bike. You can use one from an existing bike or buy a frame designed for e-bikes. The frame should be sturdy and compatible. It must be strong enough to handle the weight of a battery and motor.

The wheels

There are many characteristics to consider when choosing the wheels for your e-bike. To start, they must be compatible with your e-bike’s frame and braking system. Different wheels are designed for disc or rim brakes.

You’ll also want to consider the terrain you’ll typically be riding on. There are wheels designed for various conditions — such as road, off-road, or a combination.

Generally, e-bikes are heavier than conventional bikes due to the added weight of the motor and battery, so it’s also critical to check the wheels’ weight capacity to ensure they can handle the load without compromising safety and performance.

Additionally, if you’re going to install a hub motor, the wheels must be compatible with the motor specifications. The bottom bracket and chain-stay clearance are also essential considerations for mid-drive motors.

The brakes

E-bikes travel faster than conventional bicycles, so good brakes are an essential safety measure. E-bikes typically use disc or rim braking systems.

Disc brakes (hydraulic or mechanical) are more powerful and provide better performance, especially in wet conditions. They tend to be the braking system of choice. Rim brakes are lighter but might offer less control in adverse weather conditions. You’ll also want to consider brake pads, which come in different materials, for better braking performance.

Although e-brake sensors are optional, they’re recommended. These sensors immediately shut off the electric motor as the brake lever is pressed to ensure safety. They’re also helpful for activating regenerative braking on the electric motor. Regenerative braking systems capture and convert kinetic energy back into electrical energy, charging the battery. While regenerative braking can extend the bike’s range, it should not replace standard brakes.

The drivetrain

An e-bike’s drivetrain is made up of the components that transfer power from the motor to the wheels. The drivetrain typically consists of a chain, cassette, derailleur, freewheel, and torque sensor.

The chain transfers power from the crankset to the cassette (rear cogs). The cassette provides different gear ratios for climbing, cruising, or tackling challenging terrain. You might need to adjust the drivetrain, such as the chainrings and cassette, to accommodate the motor.

The derailleur shifts the chain across the cassette and changes gears. The freewheel lets the wheels spin freely when coasting, even with the motor engaged. The torque sensor measures pedaling force and adjusts motor assistance to provide a smooth riding experience. The derailleur and torque sensor are optional but recommended.

The electric motor

The motor is the heart of an electric bike and what differentiates it from a typical bicycle. The motor converts electrical energy from the battery into mechanical power to propel the bike forward. Choosing between a pedal-assisted (pelec) or a fully electric bike depends on several factors, including your budget and bike preferences for speed and performance.

In pedelecs, mid-drive motors are commonly used and positioned near the pedals to assist with pedaling. Usually, pedelecs are also equipped with sensors to detect the rider’s pedaling motion and force. The system then provides electric assistance in proportion to the rider’s effort.

In an electric-only system, the bike fully relies on an electric motor. It uses a brushed or brushless hub motor mounted in the wheel. Some electric-only bikes (even with hub motors) incorporate internal gear hubs within the wheel to eliminate the need for a derailleur and cassette. However, most hub motors are not connected to the bike’s gears, proving somewhat less efficient in challenging terrain. E-bikes typically only have one gear, offering limited torque or speed that the entire gear range can provide.

Some high-performance electric-only bikes also employ mid-drive motors for improved power transfer, weight distribution, and smooth riding experience.

When selecting an electric motor for your e-bike, the most important factor to consider is its power rating. The electric bike motors have power ratings from 200 to 1000W or more. A motor with a higher power rating can handle more torque but requires a larger capacity battery. A higher power rating motor will drain the battery faster despite delivering more torque. Speed-pedelec e-bikes with a motor of more than 750W require registration or license.

The battery

The battery is the heaviest and most costly part of an e-bike, providing the power to run the motor. All modern e-bikes run on lithium-ion (li-on) batteries, which are relatively light, powerful, and offer a long cycle life. Li-ion batteries typically last six or seven years and are eight to 10 times lighter than other battery types.

A li-ion battery’s cells are arranged in series and parallel, determining the battery pack’s voltage and capacity (amp-hours or Ah). The voltage of e-bike batteries ranges from 24 to 72 volts, and the capacity ranges from 250 and 1000Wh. The battery capacity is measured in watt-hours, which influences the range of the e-bike.

For most e-bikes, a battery with a capacity of 250 to 350Wh is sufficient to travel 25-40 km on a single charge. The 400-500Wh batteries can extend that range to 40-65 km on a single charge. High-performance e-bikes use 600 to 750Wh batteries, offering 65-95 km or higher on a single charge. The 1000Wh batteries are typically used in cargo e-bikes or for heavier riders.

E-bike batteries are usually cylindrical. When choosing or maintaining an e-bike battery, it’s essential to follow the manufacturer’s recommendations and guidelines. Regular charging, avoiding deep discharges, and storing the battery in a cool, dry place can help maximize its lifespan and performance.

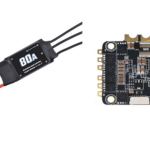

The motor controller

The motor controller is responsible for regulating the power from the battery to the motor, protecting it from damage. It manages the speed based on the rider’s input and settings. It must be compatible with the battery and motor voltage.

Most e-bikes have brushless motors, which cannot run without alternating current. So, a motor controller converts dc voltage from the battery pack into three-phase alternating current for the motor windings.

In pedelecs, the motor controller is placed on the handlebar and is used to adjust the level of assistance needed in pedaling.

In electric-only e-bikes, a throttle-based controller is typically used. There are two types of throttles: twist-grip and thumb-press. The throttle regulates the voltage from 0v to the full battery voltage delivered to the motor, increasing speed or electric assistance. The throttle is either pressed down or pulled back for acceleration or assistance.

Throttle or Pedal Assist System (PAS)

A throttle allows an e-bike rider to manually control their speed based on the motor’s power. Alternatively, a PAS “senses” the rider’s pedaling and automatically adjusts the motor’s assistance based on pre-defined levels.

There are different types of throttles, such as thumb throttles and twist/lever throttles. Twist-grip throttles rotate the handgrip, and thumb-press throttles function by pressing the thumb on a paddle.

The throttle is connected to motor controller via a throttle input plug. Typically, a magnet and hall sensors are used by all throttles to determine the throttle position. When the throttle is off, they supply 0.8–0.9V; when the throttle is engaged, they increase to 3.6-4V.

Wiring and connectors

Proper wiring and connectors are required to fasten the e-bike’s components safely. The wires should be neatly routed and secured to ensure safety and reliability.

Charger

A compatible charger is necessary to charge the battery and must match the specifications of the battery. It’s advisable to stick to the manufacturer-recommended charger to prevent damage to the battery.

PAS and torque sensor

The PAS sensor is required in a pedelec to detect the rider’s pedaling motion and adjust the motor assistance accordingly. A PAS sensor could be a speed, torque, or cadence sensor. Some PAS use a combination.

Display/Control panel

A control panel displays information such as the e-bike’s speed, battery level, and pedal assist level. It’s usually mounted between the handlebars.

Lights

Lights are essential for safety when riding at night.

Fenders

In rainy conditions, fenders will assist in keeping a rider dry.

Suspension

Quality suspension makes the ride more comfortable, especially on rough terrain. An e-bike can have only front suspension, only rear, or full suspension.

Cargo rack

You can install a cargo rack to carry groceries or other gear in your e-bike.

You may also like:

Filed Under: Tech Articles

Questions related to this article?

👉Ask and discuss on EDAboard.com and Electro-Tech-Online.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.