In the previous tutorial, we learned about the practical construction of a capacitor and the different technical aspects associated with a standard capacitor. Let us now discuss different types of commercial capacitors and the practical technical specifications associated with them. This will help immensely in choosing the suitable capacitor for a given application. The capacitors are classified based on the dielectric material used by them as follows:

1) Paper

2) Mica

3) Plastic Film

4) Glass

5) Ceramic

6) Electrolytic

7) Semiconductor

8) Variable

Paper capacitors

Paper capacitors are one of the earliest types of capacitors. They are made by placing paper soaked with mineral oil between two aluminum foils. The entire assembly is rolled up, wire leads are attached to the aluminum foils, and the assembly is enclosed in a cylindrical cardboard case and sealed with wax.

Paper capacitors are bulky and have nearly been replaced by plastic film capacitors. They can still be found in some electrical applications — most ceiling fans and air coolers still use paper capacitors. These capacitors have the following technical specifications:

Mica & Metalized Mica capacitors

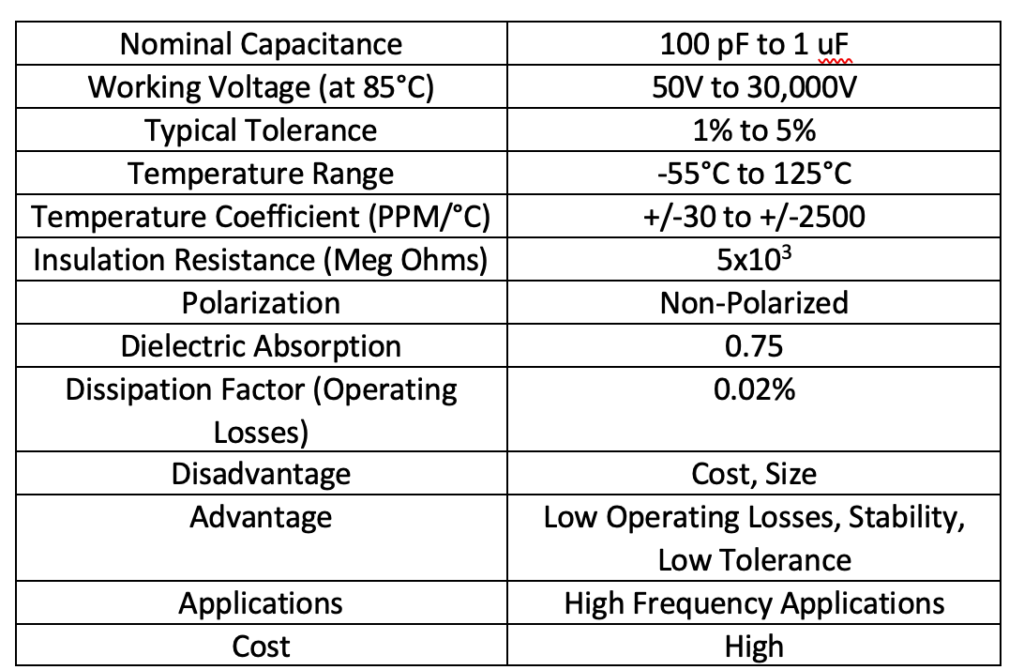

Mica capacitors use mica sheets as a dielectric and are usually constructed as multi-plate capacitors. Various mica capacitors use silver-inked mica sheets as a dielectric for better immunity to moisture and ionization. Mica capacitors are known for low tolerance (as low as 1%), low operating losses (dissipation factor of 0.001%), high-quality factor, and stability at high frequency. However, these capacitors are quite bulky proportional to their capacitance. Mica capacitors have the following technical specifications:

Plastic film capacitors

Film capacitors include many families of capacitors that use different plastics as dielectric materials. They have nearly replaced the paper capacitors in audio, radio circuits, and circuits operating at low to moderate voltages. Some of the commonly used plastics in film capacitors include Polycarbonate, Polyester (PET), Polypropylene (PP), Polystyrene, Polysulphone, Parylene, Kapton Polyimide, Teflon (PTFE Fluorocarbon), and Metalized Polyester (Metalized Plastic). These capacitors come in various geometries such as oval or round wrap and fill, rectangular epoxy case, round epoxy case, metal hermetically sealed rectangular or round case, and radial or axial leads. Some of the popular plastic film capacitor families are described below.

1) Polycarbonate (PC) Film – These capacitors are known for their long life, low operating losses over a wide range of frequencies, and nearly replaced Polycarbonate capacitors. These capacitors have the following technical specifications:

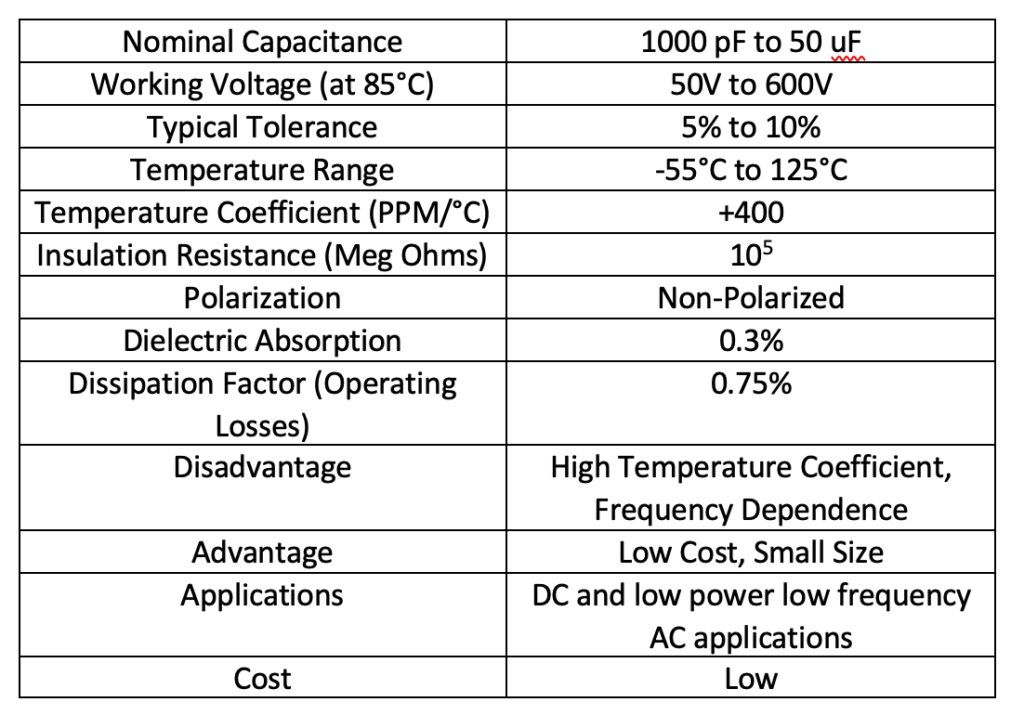

2) Polyester (PET) Film – These capacitors are popular for their low cost and small size. They have mostly replaced metalized plastic and polystyrene capacitors in DC and low-frequency AC applications. These capacitors can be used with voltages as high as 60,000 V but are not suggested for high power applications due to significant operating losses at high temperatures and frequencies. These capacitors have the following technical specifications:

3) Polypropylene (PP) Film – These are the most popular plastic film capacitors and are known for low-temperature coefficient, low operating losses, low moisture absorption, and stability at high temperature and high power. However, these capacitors are prone to damage and breakdown due to transient overvoltages and voltage reversals. They have the following technical specifications:

4) Polystyrene (PS) Film – These capacitors are known for their narrow capacitance and high stability and are rapidly being replaced by PET capacitors. These capacitors have the following technical specifications:

5) Polysulphone Film – Polysulphone capacitors are similar to Polycarbonate capacitors and are known for their thermal stability. There are limited manufacturers of these capacitors, which are not readily available. These capacitors have the following technical specifications:

6) Kapton Polyimide Film – These capacitors have the highest dielectric strength and can have operating temperatures as high as 250°C. However, these high-cost capacitors are not suitable for RF applications. These capacitors have the following technical specifications:

7) Teflon (PTFE) Film – These bulky and expensive capacitors are best known for their low operating losses, wide temperature range, and excellent stability in critical applications. These capacitors have the following technical specifications:

8) Metalized Plastic – These capacitors are improved variations of PET, PP, PEN, PPS, and Teflon capacitors. They are smaller in size compared to their non-metalized plastic versions. The only limitation of these capacitors is their low ripple current ratings.

8) Metalized Plastic – These capacitors are improved variations of PET, PP, PEN, PPS, and Teflon capacitors. They are smaller in size compared to their non-metalized plastic versions. The only limitation of these capacitors is their low ripple current ratings.

9) Foil – These are foil film versions of PP, PET, and Teflon Capacitors. These are known for pulse stability and better ripple current ratings.

Many other types and variations of plastic and plastic film capacitors exist, including film-based power capacitors. Popular film-based power capacitors include Metalized Paper Capacitors, Paper Film/Foil (Kraft Paper) Capacitors, Metalized Polypropylene (Single or Double Side Metalized PP) Capacitors, PP Film/Foil Capacitors, and MKV Power (Polypropylene as a dielectric between Metalized Papers as conductors) Capacitors.

Glass capacitors

These costly capacitors are best known for their robustness, stability, accuracy, and reliability in extreme environmental conditions. They are even resistant to nuclear radiation and are most suitable for military-grade applications. These capacitors have the following technical specifications:

Ceramic capacitors

Ceramic capacitors refer to a wide range of capacitors available as disc capacitors, MLC (Multi-Layer Ceramic) capacitors, and SMD capacitors. The composition of these capacitors varies with the manufacturers. Some commonly used materials in constructing ceramic capacitors include strontium titanate, titanium oxide, barium titanate, etc. The Electronics Industries Alliance (EIA) has categorized ceramic capacitors into the following three classes:

Class 1 Ceramic Capacitors – These are the best of the ceramic capacitors offering the lowest tolerance, thermal stability, and low operating losses, and are most suitable for high-frequency applications. These capacitors are composed of titanium oxide with other additives like Magnesium, Cobalt, Calcium, Zinc, Niobium, etc. These capacitors have their own EIA codes for specifying their nominal capacitance and tolerance. These capacitors have a high dielectric constant ranging from 5 to 150. All the advantages of Class 1 Ceramic Capacitors come on the cost of their size. These capacitors have the following technical specifications:

Class 2 Ceramic – Class 2 Ceramic Capacitors are less stable and accurate than Class 1 Capacitors. However, these capacitors are smaller compared to the latter. These, too, have their own EIA codes for specifying their capacitance and tolerance. These capacitors have the following technical specifications:

Class 3 Ceramic – These capacitors are the least stable and accurate among ceramic capacitors, with other drawbacks like non-linear temperature dependence, voltage dependence, and high operating losses. They have a short lifespan and cannot withstand high voltages. However, they have high permittivity (up to 50,000) and are compact (have few millimeter dimensions). Other types of capacitors have already replaced Class 3s, and the EIA no more standardize them.

Electrolytic capacitors

Electrolytic Capacitors are polarized capacitors that offer high capacitance per unit volume. Since these capacitors are polarized, they must be hooked up in a circuit with the right polarity. They have one terminal as the anode, a metal plate coated with metal oxide; a liquid or solid electrolytic serves as the cathode. When DC current flows through the electrolytic capacitor, the metal plate starts oxidizing due to an electrolytic. A thin insulating metal oxide layer is deposited on it, which is a dielectric. The metal oxide layer is extremely thin, so it offers very high capacitance per unit volume. Generally, these capacitors are designed to maximize the surface area of the anode.

When connecting these capacitors in reverse polarity, the electrolyte emits gas, which expands in the sealed body of the capacitor and may lead to an explosion. These capacitors have a significant leakage current, which makes them unsuitable for many applications. The electrolytic capacitors come available in the following three families:

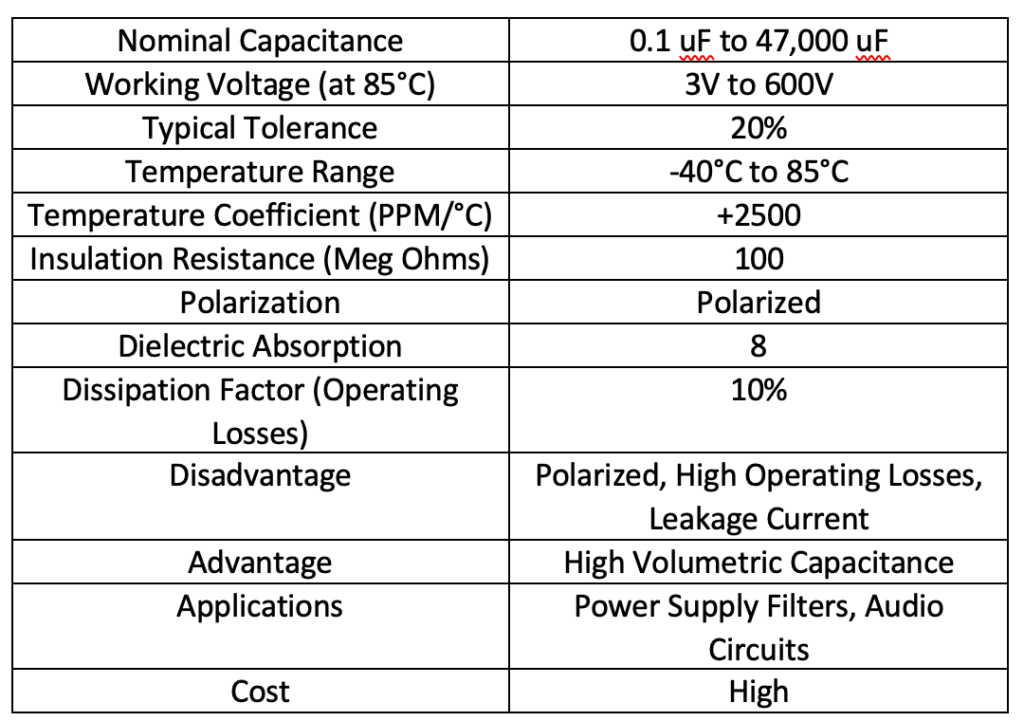

1) Aluminum Electrolytic – These capacitors use aluminum foil as an anode and aluminum oxide as a dielectric medium. They can have Ethylene Glycol, Dimethylacetamide, gamma-Butyrolactone, or Dimethylformamide as a liquid electrolytic, Manganese Dioxide, or conductive polymer as a solid electrolytic. These capacitors have the following technical specifications:

2) Tantalum Electrolytic – These capacitors use Tantalum as an anode and Tantalum Oxide as a dielectric medium. They can have Sulphuric Acid, Manganese Dioxide, or conductive polymer as an electrolytic and are highly reliable, efficient, and smaller than aluminum electrolytic types. They are often used in military applications because of their stability and reliability. These capacitors have the following technical specifications:

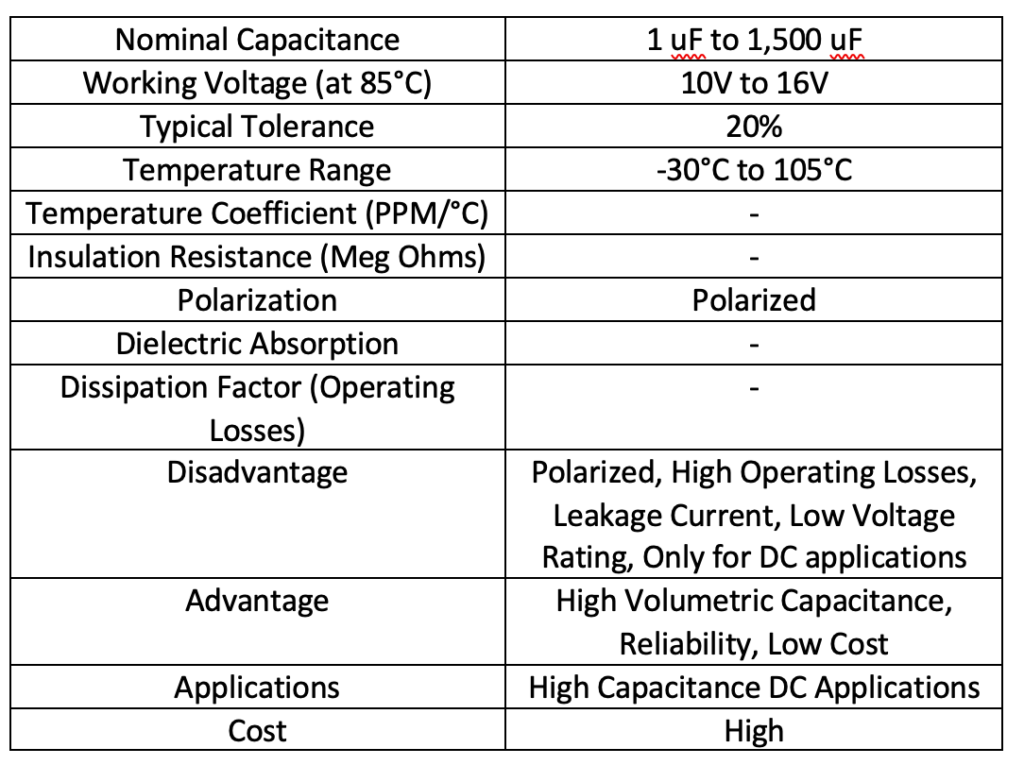

3) Niobium Electrolytic Capacitors – These capacitors use Niobium as an anode, Niobium Pentoxide as a dielectric medium, and Manganese Dioxide or conductive polymer as an electrolytic. They come available as SMD capacitors and have the following technical specifications:

Semiconductor capacitors

Semiconductor capacitors are nano-scale capacitors fabricated on integrated circuits by forming oxide layer patterns sandwiched between semiconductor materials. These capacitors are packaged as capacitor arrays and are mainly used in memory and processor ICs. Their tiny capacitances can handle low and pulsating DC voltages.

Variable capacitors

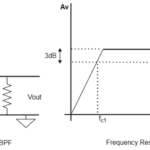

The capacitance of the variable capacitors can be varied by changing the distance between the conducting plates or by changing the mutual surface area between overlapping plates. The common types of variable capacitors are the following:

1) Air Variable (Air-Gap Trimmer) – These variable capacitors have a rotatable set of plates called a rotor, and a fixed set of plates called a stator. The capacitance is varied by rotating a control shaft which varies the distance or surface area between the plates. These capacitors can have a capacitance of a few Picofarad to 000 Picofarad and voltage rating up to thousands of volts. These non-polarized capacitors were commonly used in RF and audio circuits. Varactor diodes have almost replaced these capacitors.

2) Ceramic Trimmer – Class 1 Ceramic Capacitors are designed to offer variable capacitance. They are designed to set capacitance that does not need to be changed too often. Their capacitance can vary from a few Picofarads to 200 Picofarads. Due to their non-polarization, they can handle low to moderate voltages and are commonly used along with air variable capacitors.

3) Co-axial – These are transmission line capacitors offering capacitance between an inner and outer tube of a co-axial transmission line. Their capacitance can be varied by sliding the inner tube in or out of the outer tube. These capacitors are used in radio frequency circuits and can have capacitance from a few Picofarads to 100 Picofarad.

4) Air Gap Tuning – These are circular or logarithmic variable capacitors that use a rotor and stator as conductors and air as a dielectric medium. These bulky and expensive variable capacitors are used in commercial electrical devices.

5) Vacuum Tuning – These are similar to air gap tuning capacitors and use vacuum as a dielectric medium. These bulky and expensive variable capacitors are used in high-power RF applications.

6) SF6 Gas-Filled Tuning – These capacitors are similar to air gap tuning capacitors and use SF6 gas as a dielectric medium for better efficiency and low losses.

The next article discusses selecting a capacitor for a given application and reading capacitor packages.

You may also like:

Filed Under: Tutorials

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.