by Sebastiano Grasso, Leonardo Agatino Miccoli, Giusy Gambino, Filippo Scrimizzi, STMicroelectronics, Catania, Italy

The automotive landscape constantly evolves, driven by the increasing demand for automation, safety enhancements, and power efficiency. Within this dynamic environment, the deployment of DC motors in automotive body applications has gained significant prominence. These versatile motors find application in both traditional combustion and modern electric vehicles, serving various functions such as door locking, window control, pump operation, steering adjustments, and powering the trunk. Employing dedicated silicon motor drivers to control DC motors provides many advantages, including enhanced reliability, user-friendliness, comprehensive monitoring and protection features, and the ability to implement advanced driving capabilities.

One notable way to introduce advanced and luxurious features is by utilizing PWM (Pulse-Width Modulation) input signals to drive motors. Adjusting the duty cycle of the PWM signal allows precise modulation of motor speed and torque. However, using PWM signals can introduce substantial electromagnetic interference (EMI), potentially leading to complications such as radio frequency interference and signal distortion. In severe cases, EMI can pose serious safety risks by interfering with critical vehicle systems like airbags, anti-lock brakes, and electronic stability control. Therefore, it becomes imperative to meticulously design and operate both the motor and its control circuitry to minimize EMI and ensure the reliable operation of all electronic systems within the vehicle. This objective can be accomplished through prudent component selection, sound grounding and shielding techniques, and effective filtering mechanisms that reduce switching noise and other sources of EMI.

Steering column motor control

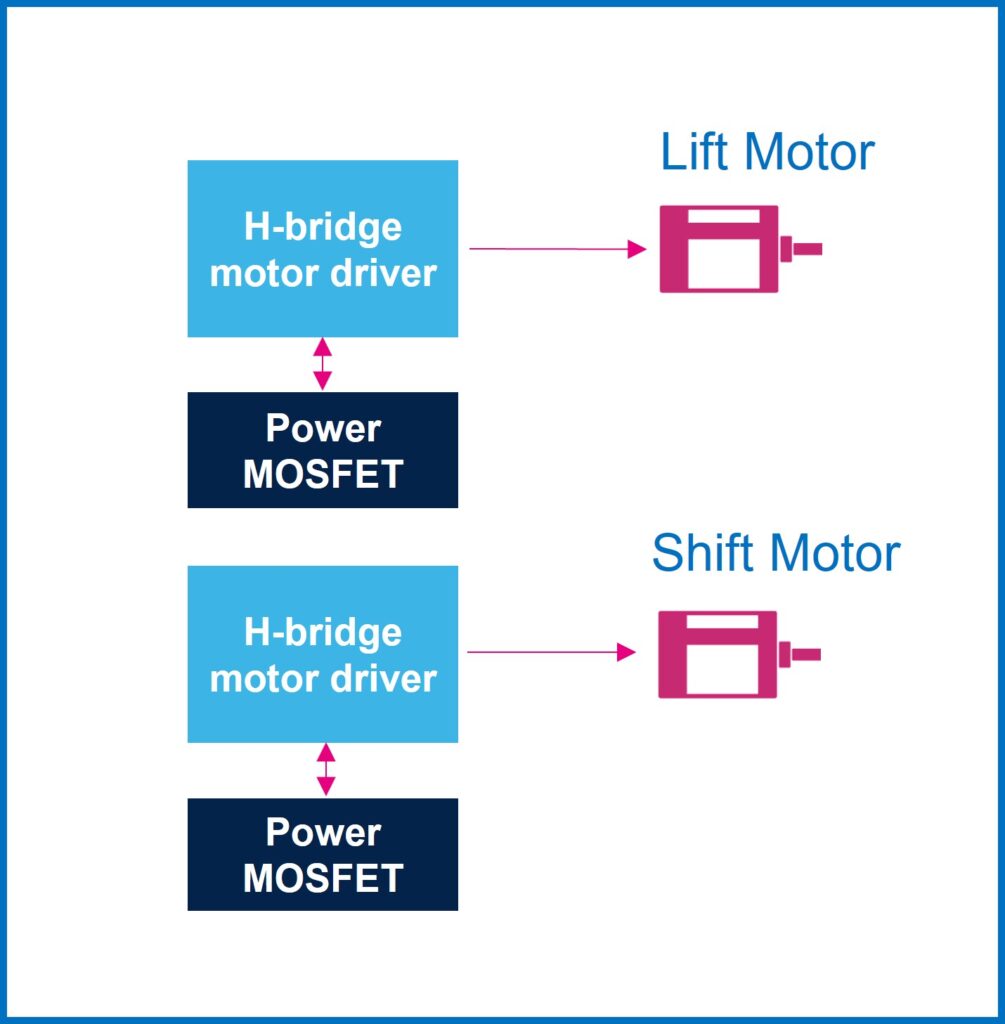

Automakers increasingly turn to brushed DC motors for vehicle steering column applications to enhance the driving experience, improve driver comfort, and bolster safety measures. Within the steering column, lift and shift motors are commonly used to adjust the height and position of the steering wheel. The lift motor facilitates raising or lowering the steering column to accommodate drivers of various heights, while the shift motor allows forward and backward movement of the steering wheel to ensure a comfortable driving position. Fig. 1 illustrates a typical block diagram for this application.

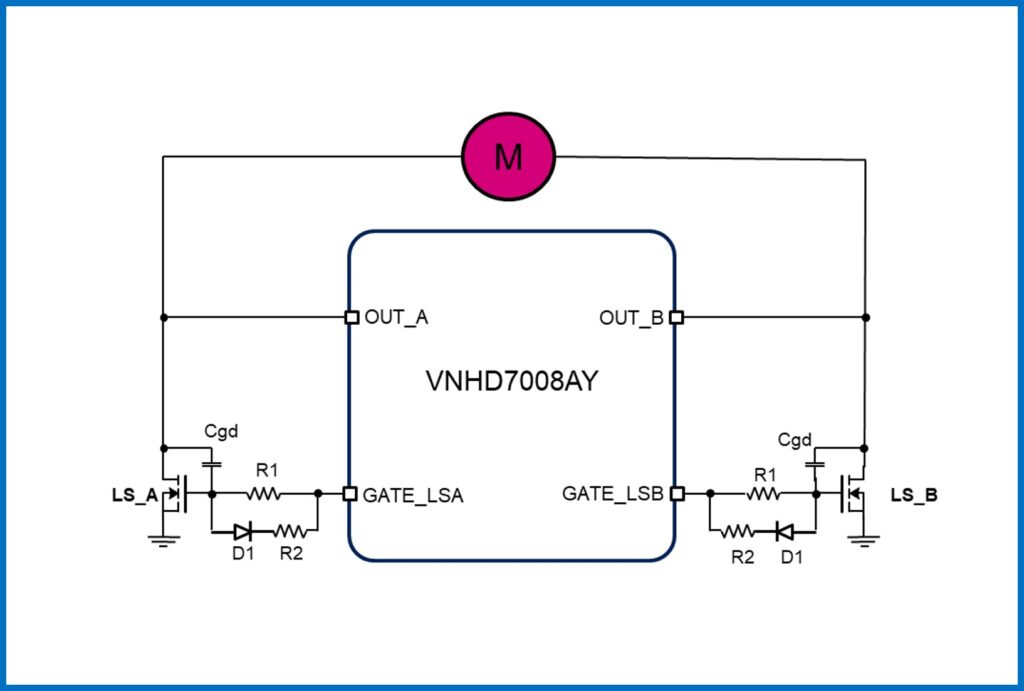

The typical architecture to drive a bidirectional DC motor is the H-bridge configuration. The ST VIPower M0-7 VNH7 family presents various DC motor drivers specially tailored for automotive applications. Combining logic functions and power structures within a single package, these VIPower M0-7 H-bridges offer capabilities for driving, protection, fault management, and advanced diagnostic features, all while minimizing the physical footprint. Among these, the VNHD7008AY and VNHD7012AY models are excellent choices for controlling steering column actuators. Housed within the PowerSSO-36 package, they ensure straightforward integration into new or existing designs. The VNHD7008AY/VNHD7012AY requires two external power MOSFETs to complete the driver functionality. STMicroelectronics’ high-performance products, the STL76DN4LF7AG and STL64DN4F7AG, are designed based on the STripFET F7 technology and carry AEC Q101 qualification, making them ideal for automotive applications. The dual-island PowerFLAT 5×6 package is another noteworthy feature, conserving precious PCB space.

The VNHD7008AY / VNHD7012AY empower dual motor operation in clockwise and counterclockwise modes, with a frequency of 20 kHz and pulsed power supply featuring an 85% duty cycle.

EMI Testing

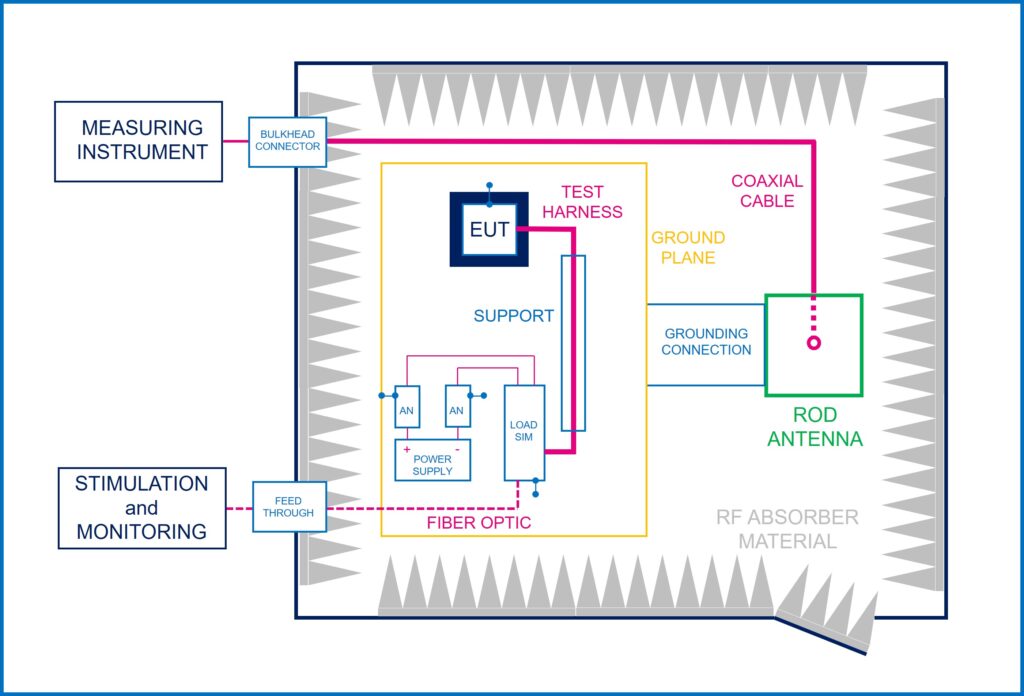

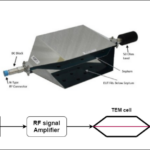

For EMI measurement within a specific frequency range, a specialized setup employing a rod monopole antenna in accordance with the international CISPR 25 standard is deployed. These measurements are conducted in an anechoic chamber to minimize external interference, as depicted in Fig. 2.

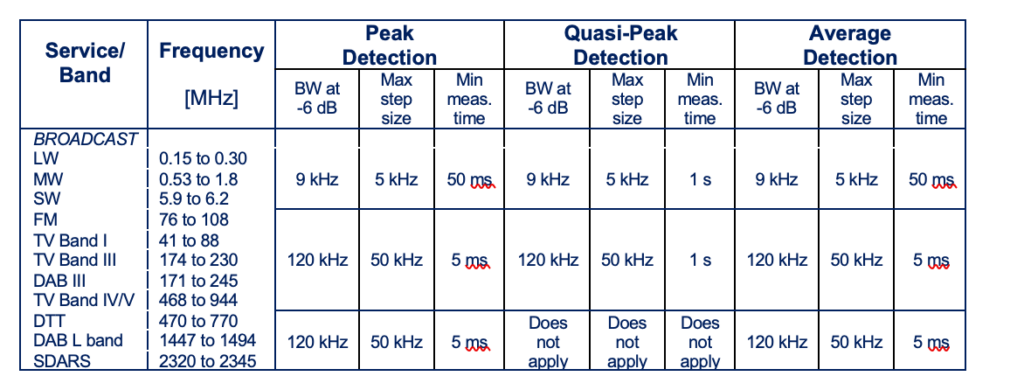

This setup comprises various components, including the equipment under test (EUT), which is locally grounded in compliance with the test plan, a load simulator (Load sim), an artificial network (AN), and a support structure with a low relative permittivity (εr ≤ 1.4). The rod antenna used in the setup typically measures 600 mm by 600 mm, ensuring precise and reliable EMI measurements through an emission test receiver positioned outside the chamber. The receiver’s parameters align with the CISPR 25 standard, as detailed in Table 1.

The table provided above (Table 1) displays different types of broadcasts, which are defined as follows:

- LW: Long wave

- MW: Medium wave

- SW: Short wave

- FM: Frequency modulation

- TV band: Television band

- DAB: Digital audio broadcasting

- DTT: Digital terrestrial television

- SDARS: Satellite digital audio radio service.

Guidelines for EMI mitigation

The experimental results inform us about guidelines for optimizing EMI in a steering column application employing either the DC motor driver VNHD7008AY or VNHD7012AY.

- Initial Condition

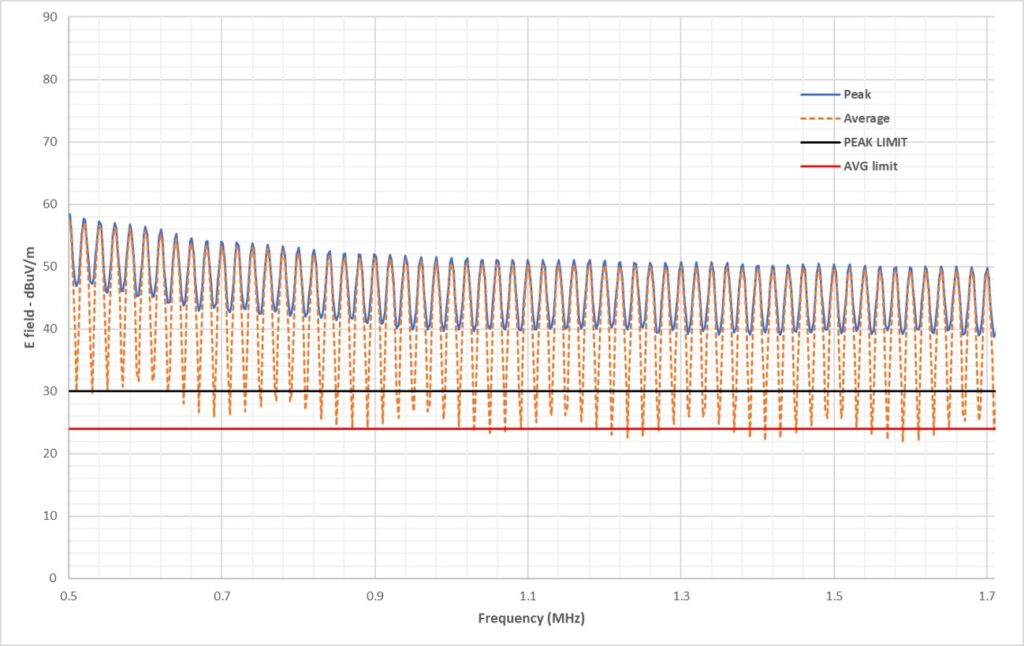

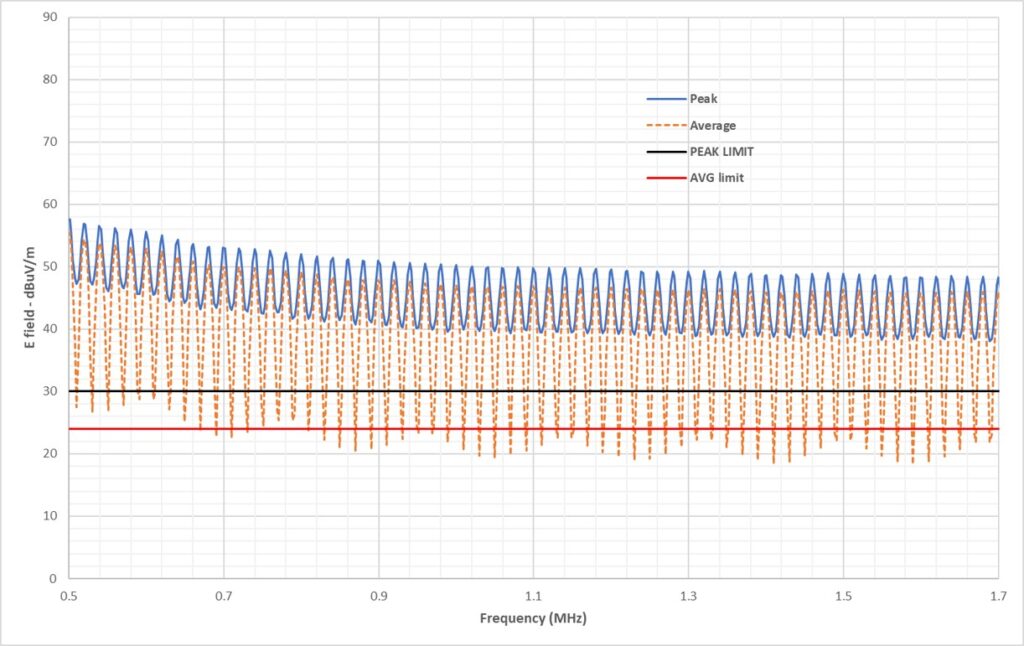

The steering column lacks grounding in the original application board, and no compensation network is in place. Emissions are recorded using peak and average detectors, as shown in Fig. 3.

The AM (amplitude modulation) band, encompassing LW, MW, and SW, exhibits elevated emission levels. Notably, emissions within the frequency range of 0.5 MHz to 1.7 MHz surpass specified limits.

- Ground Connection

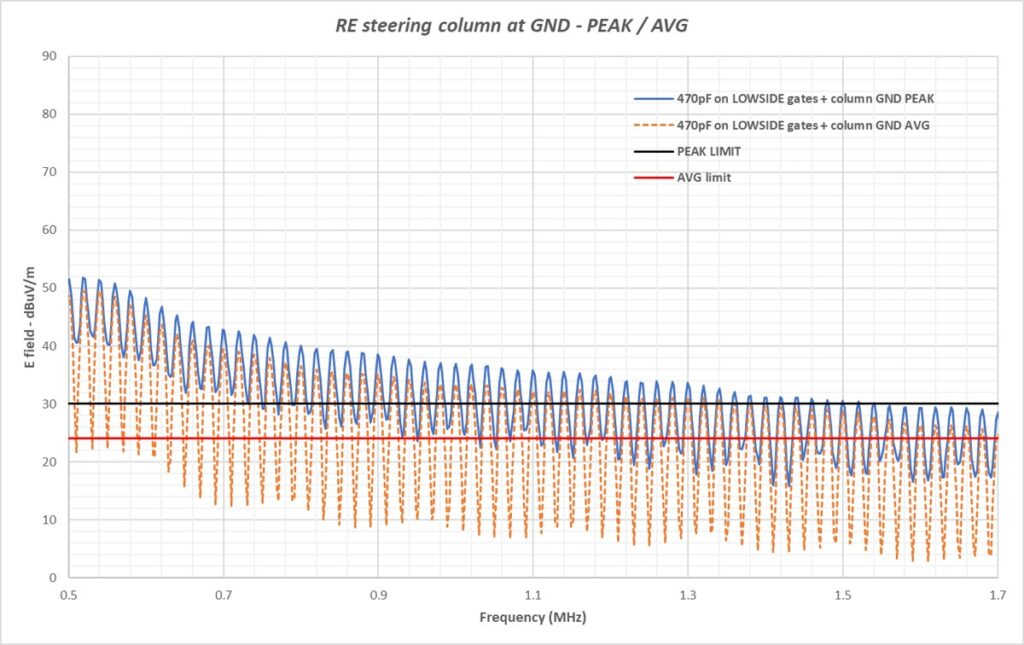

One effective guideline, validated through experimentation, involves directly grounding the steering column body. The emission profiles for both average and peak values following this modification are presented in Fig. 4.

Analysis reveals that grounding the steering column body enhances EMC (Electromagnetic Compatibility) performance. Nevertheless, it’s worth noting that these emissions primarily stem from the harmonics of the PWM (Pulse-Width Modulation) signal and the sharp, asymmetric edges of the rising and falling waveforms. Managing input noise becomes challenging due to the high current flow in the battery line, necessitating high saturation current inductor filters that can impact the application’s overall cost.

- Slowing Down the Switching Edges

To minimize emissions in the 0.5 MHz – 1.7 MHz range, reducing the speed of switching edges and optimizing the balance between rise and fall edges is recommended. Several actions can be taken, as illustrated in Fig. 5..

Incorporating an additional gate-drain capacitor increases the total gate-drain capacitance, effectively slowing down the switching phase of the LS power MOSFETs. Raising the gate resistance of the MOSFETs and introducing an asymmetrical gate-driving circuit balances the rising and falling switching waveforms. Modifying the capacitance value of the input filter further aids in reducing emissions within this frequency band.

3.1 Extra Gate-Drain Capacitor

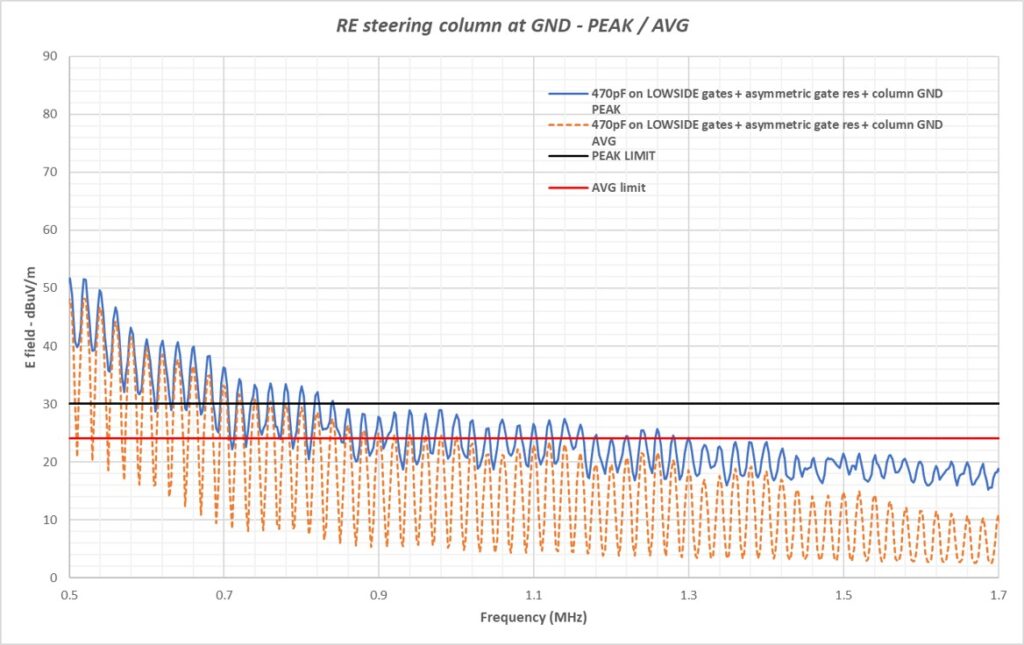

The addition of an extra gate-drain capacitor to the LS external power MOSFETs results in an average reduction of emissions by approximately 10 dBµV/m in the frequency range of 0.5 MHz to 0.8 MHz and about 20 dBµV/m between 0.8 MHz and 1.7 MHz. This improvement remains consistent regardless of whether the steering column body is grounded, although grounding can further reduce electromagnetic interference and improve overall system performance. A maximum value of 470 pF for the extra gate-drain capacitor is recommended to prevent abrupt system shutdown. Excessive increase in the rising switching slope can trigger the VDS (drain-source voltage) protection embedded within the VNHD7008AY / VNHD7012 (specifically designed to safeguard the motor against shorts to the battery line). While higher capacitance values (up to 560 pF) may be acceptable, they are not recommended due to variations in capacitance values and temperature range tolerance. A 470 pF value ensures a safe margin, accounting for these factors. Fig. 6 showcases the best results attainable with this circuit modification, incorporating the extra gate-drain capacitor and a grounded steering column.

and extra gate-drain capacitor.

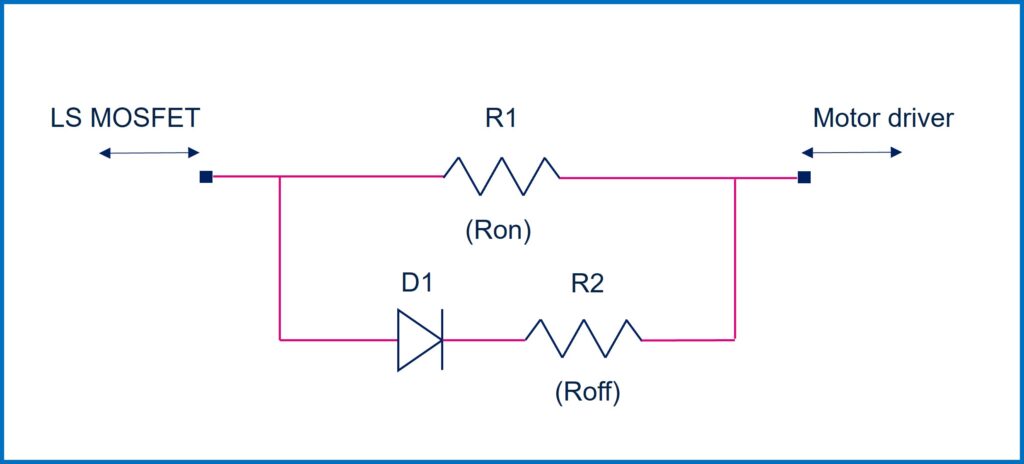

3.2 Asymmetric Gate Driving

This circuit optimization involves increasing the resistance from the DC motor drivers’ output to the LS MOSFETs’ gate, as indicated in Fig. 7.

To reduce electromagnetic emissions, two solutions can be implemented. The first solution entails increasing the gate resistance (R1) from 470 Ω to 1 kΩ. The second solution involves introducing a diode (D1) with a resistance (R2) set at 470 Ω to achieve asymmetrical gate driving. Additionally, increasing the gate-drain capacitance can result in more balanced switching waveforms with smoother rising and falling edges on the motor’s terminals. Fig. 8 demonstrates the effectiveness of these solutions in reducing emissions, assuming a grounded steering column body.

and asymmetrical gate driving.

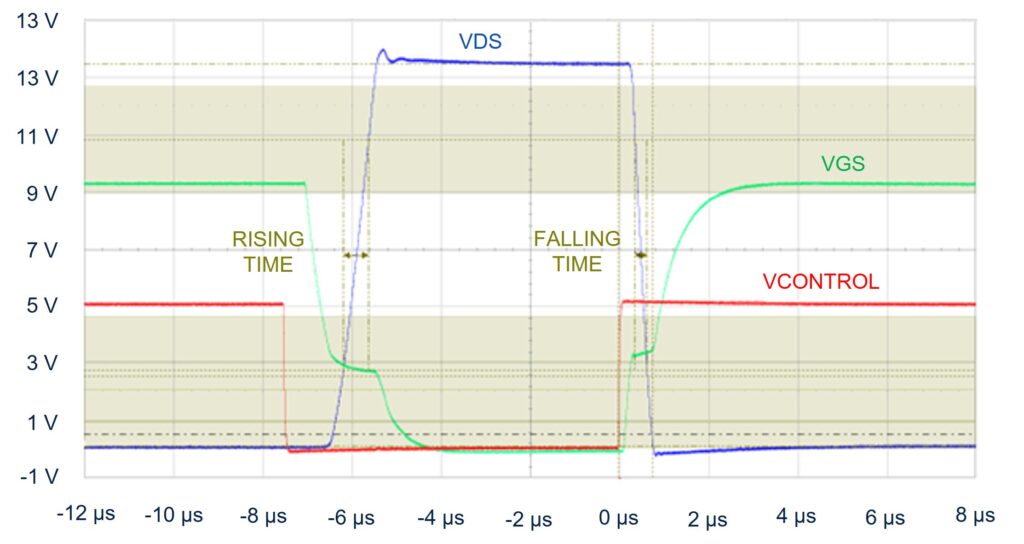

This proposed solution keeps emission levels below the normative limits of the CISPR 25 standard within the frequency range of 0.9 MHz to 1.7 MHz. To clarify the effect of the asymmetric gate driver, it is worth considering some test measurements conducted on an application board loaded with a dummy resistive-inductive (R-L) load, including a 2 Ω resistor with a 13 µH inductor. With a 470 Ohm gate resistor mounted on the LS MOSFET gates, the falling switching edges are significantly faster (about 170 ns) than the rising edges (about 800 ns). Introducing the asymmetric gate driver with specified values results in more balanced falling and rising switching waveforms. Fig. 9 provides a visual representation of these waveforms.

In summary, the combination of balanced rise and fall switching times and controlled switching speed leads to an overall reduction in emission levels, particularly in the frequency range associated with EMI.

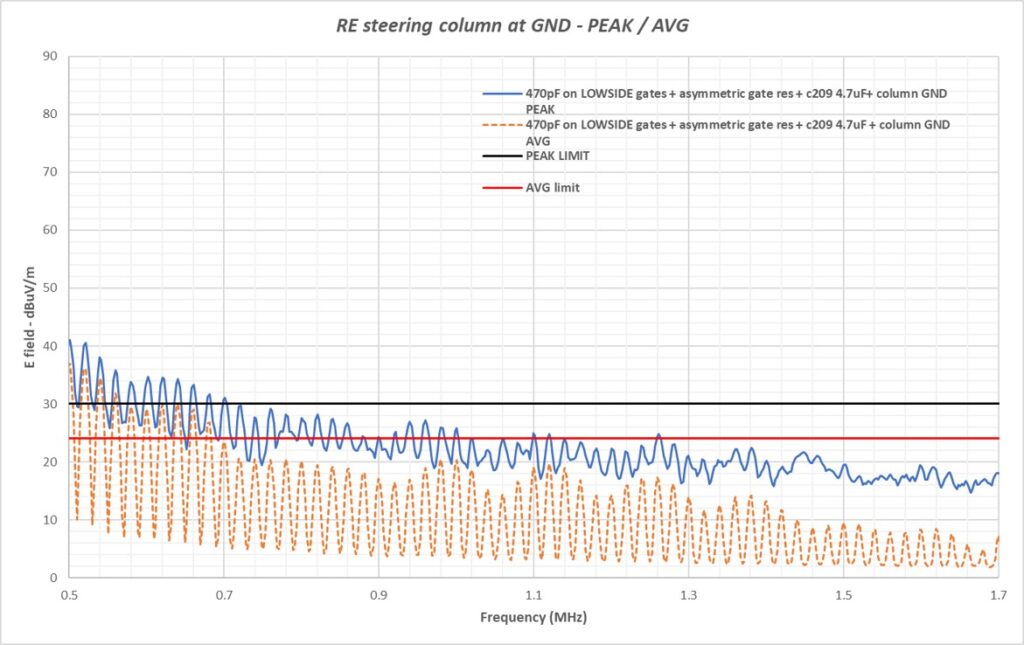

3.3 Extra Filtering Capacitance

Including an extra capacitor in the input filter equipped with a 1 µH inductor is advisable to further reduce emissions, particularly in the lowest frequency range. The cumulative impact of all the suggested modifications is demonstrated in Fig. 10, showcasing both peak and average measured spectra.

While a minor frequency interval may still exhibit emissions exceeding standard limits, this can be addressed by implementing an additional input filter, offering potential performance improvements ranging from a minimum of 10 dBµV/m to a maximum of 30 dBµV/m. However, this may have cost implications for the overall application.

Conclusions

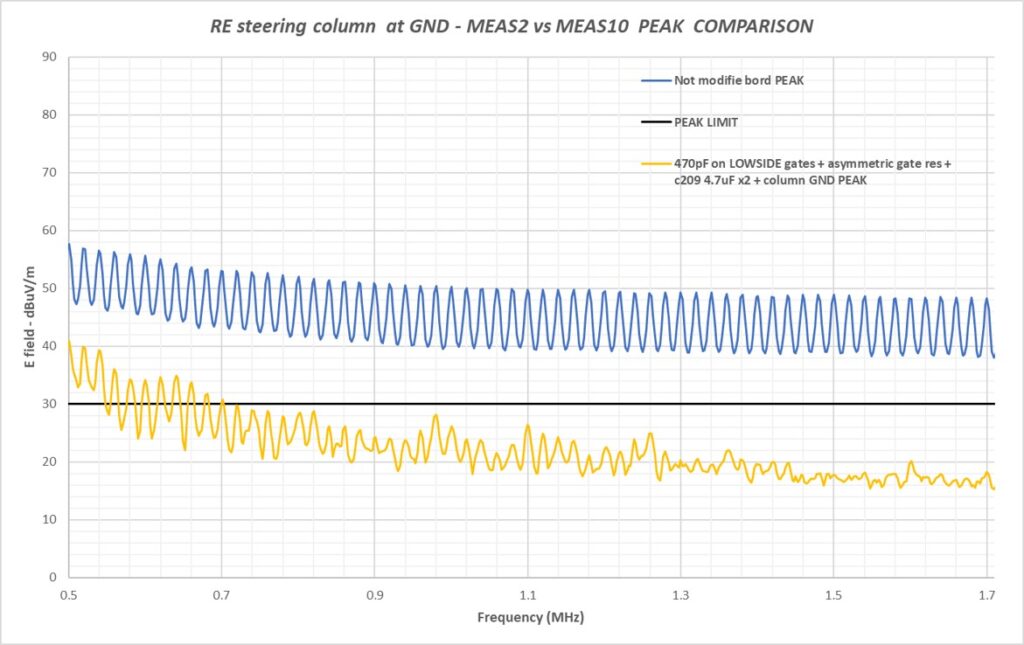

A comparative analysis of the emission spectrum in the initial scenario (blue line) and the proposed solution (yellow line) is presented in Fig. 11, summarizing the overall enhancements achieved.

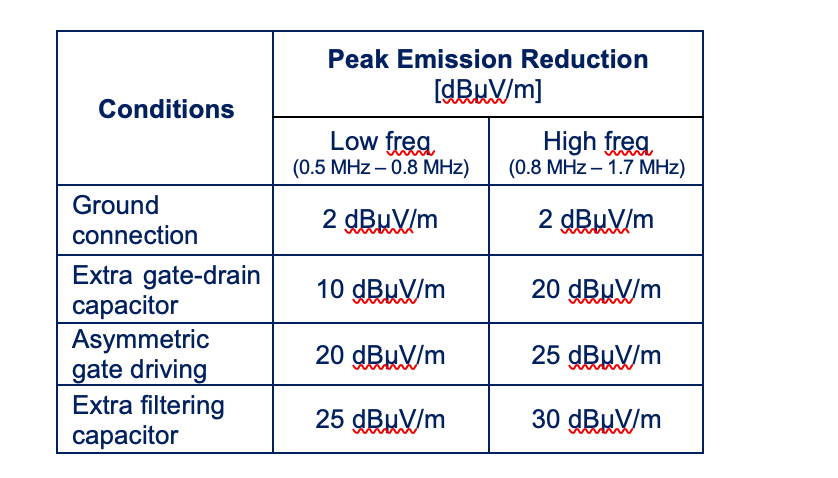

The recommended modifications to the application effectively reduce the emission rate of a DC motor control system, ensuring compliance with the CISPR-25 standard specification limits within the 0.5 MHz – 1.7 MHz frequency band. Table 2 summarizes the average reduction in peak emissions achieved through the sequential implementation of different solutions.

The results underscore the effectiveness of the proposed modifications in reducing emission rates in a DC motor control system application and ensuring compliance with the CISPR-25 standard specification limits. This is paramount for the dependable and secure operation of the system.

You may also like:

Filed Under: Applications, Automotive, Power, Tutorials

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.