Vehicles and public transit have become the primary modes of transportation for many daily commuters. However, bicycles have remained an option for some due to cost or lifestyle — and this choice is increasing. One reason is that there are more two-wheel choices than ever before. And specifically, motorized bicycles or e-bikes have gained much…

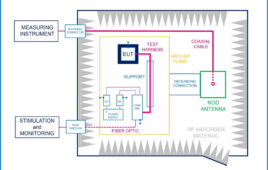

Minimizing electromagnetic interference in smart motor control for automobiles

by Sebastiano Grasso, Leonardo Agatino Miccoli, Giusy Gambino, Filippo Scrimizzi, STMicroelectronics, Catania, Italy The automotive landscape constantly evolves, driven by the increasing demand for automation, safety enhancements, and power efficiency. Within this dynamic environment, the deployment of DC motors in automotive body applications has gained significant prominence. These versatile motors find application in both traditional combustion…

Infineon teams with Infinitum to drive decarbonization

At APEC 2023, Infineon Technologies announced that the company is joining forces with Infinitum, creator of the sustainable, breakthrough air core motor. In this technology collaboration, Infineon will provide silicon-carbide (SiC) CoolSiC MOSFETs and other key semiconductor components that greatly contribute to the Infinitum motor system’s precise motor control, optimal power, and energy savings. The…

New motor-drive reference designs include STSPIN32 and production-ready PCB

STMicroelectronics has released two reference designs that simplify building complete industrial or home-appliance motor drives for compressors with the STSPIN32 motor-control system-in-package (SiP). Each integrates the motor controller with a three-phase inverter to power the motor, and an offline converter and auxiliary circuitry. A production-ready PCB design and motor-control firmware are also included. The STEVAL-CTM011V1 targets general…

Renesas launches programmable gate driver for BLDC motor applications

Renesas Electronics Corporation, a supplier of advanced semiconductor solutions, is introducing the RAA227063 Smart Gate Driver for brushless DC (BLDC) motor applications. The new device is programmable via an SPI interface, enabling it to support both motors with rotor position sensors and sensorless applications. It also provides programmable gate-drive voltage, offering support for N-channel MOSFETs…

Controlling Servo Motor using Freeduino

Servo is a special type of motor which converts electric signals in to shaft positions. Servos can be broadly classified as Industrial servos and Hobby grade [[wysiwyg_imageupload::]]servos.Industrial servos are generally heavy duty high power AC or DC servos widely used for precise robotic arms.Hobby grade servos are widely used in RC Hobbies like RC Plane, Cars Helicopters, Multirotors, Boats, hover craft, etc.They are mostly used to control the control surfaces (RC Planes) or for thrust vectoring mechanisms (hovercraft, boats, multirotors) or for steering mechanisms (RC Cars).Hobby grade servos are further classified as micro, standard, giant based on the torque they can provide, however their working principal is just the same.Based on speed of operation they are classified as Analog or Digital servos, Digital servos provide greater speed but consume more power.Speed of a servo motor is defined as time taken for shaft to move from 00 to 600 after the application of signal. In this article we will be using an ARDUINO clone board viz. FREEDUINO.

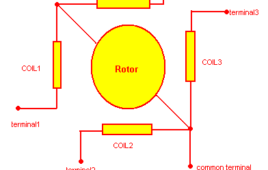

How to deal with an unknown stepper motor?

How to deal with any unknown stepper motor? This section deals with a special procedure that can be useful to find out the type of stepper motor, its terminals, its coil sequence, its step resolution and everything about stepper motor. if anyone have a steppe motor that doesn’t have any specifications then after going through this section…

H-bridge using transistor

This project and circuit finds a huge application in the area of robotics to control motor direction. This circuit uses the basic concept of transistors as a switch. H-bridge using transistorTransistor with proper biasing can be used as switch, i.e. it can be used to toggle between the two states of a switch on or off. This configuration of transistor has been used in H-bridge to drive a motor in both clockwise and anticlockwise direction. This circuit derives its name from the English alphabet “H”, which closely resembles the circuit pictorially. The circuit based project can be divided into two parts. The first part explains the concepts behind the working transistor as switch and the second part the function and operation of H Bridge. Keep on reading to find out how the circuit is constructed and what makes it work.

DC Gear motor rotation control

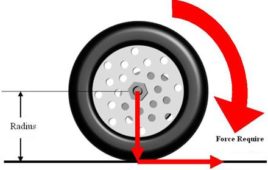

Here is very useful application that controls the number of rotation of 12 V DC gear motor with very low RPM (1,2,3,5 or 10 etc).You may find lots of [[wysiwyg_imageupload::]]applications of this project in robotics, CNC machines, manufacturing industries etc. Here are some of the examples In any PCB cutting or PVC pipe cutting CNC machine (or any other automatic cutting machine) first the linear dimensions are calibrated in terms of number of rotations (e.g. 5 rotations = 1 CM), then by adjusting the number of rotations as per required dimension one can easily move the cutting tool to that distance (e.g. for 1 meter 500 rotations). In robotic arm application, if the arm has to move to a specific position then first its movement can be calibrated in terms of number of rotations of motor. Afterwards once we program and set the number of rotations for a button, the arm will always move to that position when that button is pressed.

DC Motor Control with VC++

This project is Microsoft Windows based program written in Visual C++ to control DC motor. Visual C++ is one of the very efficient, effective more user [[wysiwyg_imageupload::]]friendly software. Let us see the main function as well as the additional features of this application. Mouse as well as keyboard interface provided. All the controlling actions at your fingertips Four degree of motion control is achieved for single motor. (1) Motor rotates continuously at constant speed (2) pulse wise rotation means motor rotates for less than one revolution (3) motor rotates with desired speed for fix duration of time (4) motor rotates till mouse button is pressed and moved. One can vary both the parameters of motor speed and direction. DC motor will rotate like stepper motor in pulse wise rotation mode. Keep on reading to find out how simple controls over DC motor can be managed using Visual C++.

How to use a PMDC Motor in Electronic Circuits

Electric motors are the most convenient devices in use which can convert the electrical energy into mechanical energy. Electrical motors converts the electrical [[wysiwyg_imageupload::]]energy to rotational motion which can then be easily converted to any kind of mechanical motion like moving a robotic arm, moving a needle in a sewing machine etc. The Permanent Magnet Direct Current (PMDC) motors are especially useful since they are very easy to control, produce a lot of power and come in various sizes, shapes and voltage ratings. When used with electrical or electronic circuits one must be careful about certain things like the current consuming, torque, RPM etc. This article mainly discusses those things and also the details of circuits which can be used to drive the PMDC motors. Continue reading to find out how PMDC motor can be easily used in electronic circuits.

Single switch motor on/off.. Clockwise/anticlockwise

Shown here is an easy to construct electronic circuit through which a motor can be made to run in both directions i.e. clockwise and anticlockwise. An interesting [[wysiwyg_imageupload::]]fact that adds to the curiosity of the circuit is that this is done by pressing a single switch. This project finds a good application in areas of robotics. The commonly used H-Bridge circuit uses two control signals to control both the directions of the motor. Before we begin explaining the circuitry, let’s have some information about the H-Bridge circuit.H Bridge CircuitMainly used to control DC motors and stepper motors, H-bridge divides the voltage on the either side of the load. In this circuit, two IC555 timers form the H-bridge circuit around the motor. These 555 timers work in astable mode. Let’s find out more about how the circuit works.

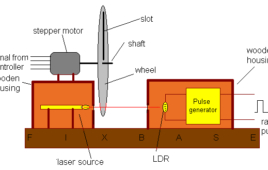

Motion Controller using Stepper Motor

This system is the example of close loop control system for maintains the speed of stepper motor constant. The speed of stepper motor is sensed and feedback to controller. Controller will compare it with set value and if there is deviation then it will either increase or decrease the speed.In most of the industries the constant speed of motor is required and that should not be fall / exceed beyond specified limit. to get the precise RPM and control stepper motor is the best.The stepper motor is placed on top of laser as shown. The slotted wheel is coupled with the shaft of motor. The wheel is such a big that it can interrupt the laser beam falling on LDR. Now as the motor rotates the slotted wheel also rotates. The beam will fall on LDR only when the slot comes. This will produce one pulse. So every time when slot come in line with LDR and laser, one pulse is produced. Thus the rotation of motor is converted in to pulse that can be counted.

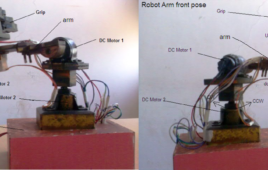

Cell phone operated Robotic Arm

This is also picked and place type robotic application. But this has a unique feature that it is controlled from cell phone. It’s all the movements are controlled from any cell phone. That means you can control this robot from anywhere in the world where GSM / CDMA network service is available. Isn’t it very interesting??!!!!????…..The robot has built in GSM / CDMA cell phone that receives signals from other cell phone. One has to call the number of the cell phone (that is inside robot) from his cell phone to activate it. Then by pressing different keys from 0 – 9 form the phone he can control the movements of the robot. It is 4-axis robotic arm. It’s all four motions are controlled by 2 DC gear motors and 2 servo motors.Let us start with mechanical structure of robot.

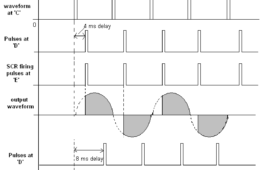

Single phase AC Motor speed controller

Here is a very simple example of AC motor speed control given by changing firing angle of TRIAC with the help of micro controller 89C2051. Varying speed of AC motor by means of changing firing angle of any thyristor is very widely used method. One very nice example is fan regulator in which a fan…

Remote controlled DC Drive

In most of the industries for motion control AC motor or DC motor are used. To control the motion there is a need of either AC drive or DC drive. The basic functions of this drive are to give smooth start to motor change the direction, change the speed etc. Here I am demonstrating one such…

Industrial control panel for Unipolar Stepper Motor

Here given project is the real control panel for any unipolar stepper motor which is designed to run motor at lower RPM (as much as upto 10 RPM) to take greater load and provide extra heavy torque. This project is for specialize stepper motor which has technical specifications like Voltage ratings: – from 5 to…

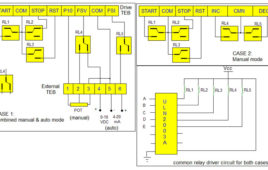

Remote control for AC Drive

AC Drive is widely used and probably a vital controlling device in the field of industrial automation. Most of manufacturing industries, continuous production units, chemical industries, textiles miles, pharmaceutical industries are now equipped with most advance industrial automation and to control various AC motors the ultimate solution is AC Drive. What’s an AC Drive? AC Drive is actually…

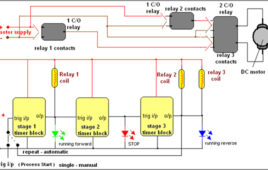

Industrial control panel for DC Motor

The name itself suggests that the project is on industrial automation and the application is developed to control any industrial DC motor. Lets first check the specifications Motor type: – DC series motor Maximum Rated Voltage:- 100 VDC Maximum rated current: – 4 Amp Power ratings: – 2 HP Maximum RPM: – 3000 Torque: – 5 to…

Temperature Dependent Fan

Obviously you might have seen so many temperature controller and indicator applications using different micro-controllers, micro-processors or other controlling devices. But this is the actual application of temperature controller that controls speed of DC fan as temperature varies. It is not a simple ON-OFF type controller that switches fan ON / OFF when temperature increases / decreases certain limit. But its continuous type controller that continuously varies speed of DC fan as temperature increases / decreases. That is a demo of actual industrial application.