In the previous tutorials, we discussed working with a capacitor, characteristics of a capacitor, various types of capacitors, and selecting a capacitor for a given circuit. As we have learned, typical commercial capacitors have their capacitance in Picofarad, Nanofarad or Microfarad range. The maximum capacitance that these capacitors can provide is 1 Farad. If the higher capacitance is required, the capacitors will need to be quite large, which may or may not fit into typical electronic circuits.

Enter the supercapacitor. These electrochemical type capacitors are small in size and can offer capacitance in tens, hundreds, or even thousands of Farad. They cannot only store a large amount of charge, but they can also go through several thousands of charge-discharge cycles without any wear or tear. That is why these capacitors, also known as ultracapacitors, are useful in many emerging technologies such as hybrid vehicles, active filters, renewable energy, UPS, smartphones, and portable electronic gadgets.

What they do

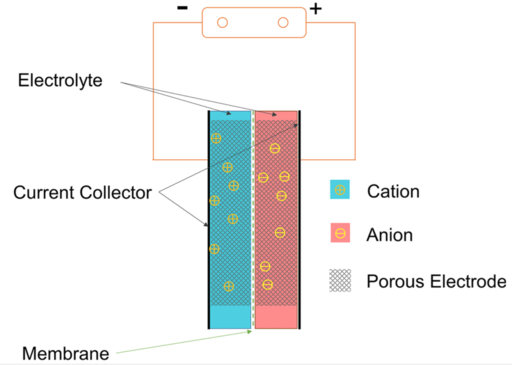

Supercapacitors are used to store a large amount of charge as an electrostatic field. Like electrolyte capacitors, these capacitors also use liquid or solid electrolytes. However, the way they store charge is entirely different. In typical capacitors, the charge is stored due to the polarization of the dielectric material. In supercapacitors, the electrolyte does not serve as a dielectric. It only supplies charge carriers to the electrodes. Instead, the charge is stored by the accumulation of opposite charge carriers on electrodes.

The electrodes of these capacitors are made up of porous activated carbon or carbon nanotubes, which are capable of attracting a vast amount of charge in them. A minimal distance separates the electrodes and has a separator between them to avoid shorting between the porous electrodes. The use of activated carbon as electrodes and a minimum distance between electrodes enable these capacitors to store a vast amount of charge in small size.

Construction

Supercapacitors are constructed somewhat like electrolyte capacitors. They have two electrodes that are made up of porous active carbon coating or carbon nanotubes. The coating is implemented on metal foils (generally aluminum) which serve as current collectors. The current collectors coated with electrodes are immersed in an electrolyte.

Schematic illustration of a supercapacitor (Image: Wikipedia)

The electrolyte can be liquid or solid. In most ultracapacitors, solid electrolytes are preferred due to higher terminal voltage. The solid electrolyte is generally a solvent mixed with conductive salts. Typically, Acetonitrile or Propylene Carbonate is used as a solvent and Tetraalkylammonium or Lithium salts as solutes. The electrode coated current collectors are separated by a separator (paper membrane) which is transparent to the charge carriers but avoid direct shorting between the electrodes. Due to the double-sided electrode coating of current collectors, these capacitors are also called Electrical Double Layer Capacitors (EDLC).

The highly porous nature of electrode material enables these capacitors to attract a large number of charge carriers from the electrolyte. Due to the use of activated carbon, the effective surface area between the current collectors is increased manyfold. The internal resistance (ESR) of the capacitor depends upon the electrolyte. The lower the resistance offered by the electrolyte, the greater is the power density of the capacitor.

Supercapacitors generally have a very low voltage rating that may range from 1V to 3V. The following equation gives the electrical power stored by a supercapacitor:

P = V2/4R

Where,

P is the power stored by the Super Capacitor,

V is the applied voltage (or Voltage Rating),

R is internal resistance (ESR) of the capacitor

How they work

When a potential difference is applied across the terminals of a supercapacitor, the electrodes start attracting opposite charge carriers from the electrolyte. The positive ions get accumulated at the negative connection, and negative ions get accumulated at the positive connection. The charge carriers are stored at the current collector plates. Due to accumulation of opposite charges at the current collectors, an electrostatic field is set up between them. Charging current flows through capacitor until the electrostatic field between the current collectors equals and opposite to the applied voltage. The charge carriers are retained by the current collectors until the applied voltage decreases or changes polarity.

Whenever the applied voltage decreases, a proportional number of charge carriers are passed back to the electrolyte from the current collectors. During this process, an equivalent current flows through the capacitor in reverse direction. When the polarity changes, the supercapacitor goes through a similar cycle of charging and discharging.

You see that the supercapacitor, despite its electrochemical construction, still stores charge in the form of an electrostatic field. It works exactly like any other capacitor. That is why, despite battery-like construction, supercapacitors are classified as capacitors and not batteries. Compared to batteries, supercapacitors can go through several thousands of charge-discharge cycles. Therefore, they can serve as an excellent source of charge or power backup in battery-operated circuits.

Practical supercapacitors

The supercapacitor cells have a very low terminal voltage rating that may range from 1V to 3V. On connecting supercapacitor cells in series, their voltage rating can be multiplied. Similarly, the parallel connection of supercapacitor cells multiplies the effective capacitance. As a result, supercapacitors are generally used as a matrix of cells where they are connected in series along the rows and in parallel along the columns. The following equation gives the final voltage rating of the pack:

V = N * VCell

Where,

V is the effective terminal voltage of the pack

N is the number of rows or number of supercapacitor cells connected in series in each column

VCell is the terminal voltage of individual supercapacitor cells

The following equation gives the effective capacitance of the pack:

C = (M/N)*CCell

Where,

C is the effective capacitance

M is the number of columns or number of supercapacitors cells connected in parallel in each row

N is the number of rows or number of supercapacitor cells connected in series in each column

CCell is the capacitance of individual supercapacitor cells

Advantages

Supercapacitors have the following notable advantages over other capacitors and batteries:

- Capable of storing a large amount of energy in the form of an electrostatic field.

- High power density and compact size, which makes them suitable to be used for storing charge for typical electronic circuits.

- Ability to charge and discharge in a short time, and can be used to meet frequent power demand peaks and can supply large power bursts for short durations.

- Do not involve electrochemical reactions, and so, do not have operational wear and tear and increases lifespan. They can be used hundreds of thousands of times without the need for replacement.

Applications

Due to their charge storage capacity, small size, and fast charging and recharging, supercapacitors have found applications in many emerging technologies. One of the main domains where supercapacitors have eventually reserved a place is the transportation industry. In electric vehicles, supercapacitors are used in the braking systems to store back EMF produced by the DC motors. The charge stored by the supercapacitors can be applied to power electrical systems of the vehicle and recharge batteries. In electric vehicles, supercapacitors can also serve as a power backup for the batteries, so smaller batteries need to be installed in them. The hybrid vehicles (which completely turn off their engine on stop) use supercapacitors to restart the engine after every stop.

A CAP-XX GW134T Thinline supercapacitor pictured with an SD card, a US dime and a credit card. (Image: CAP-XX)

Another useful application of supercapacitors is in traction vehicles. The traction vehicles undergo multiple phases of acceleration, cruising, and deceleration. The supercapacitors can be used in such vehicles to handle voltage fluctuations and operational power losses.

Today, supercapacitors are generally used along with display units of smartphones, laptops, and computers to power up the screen in a short time. These are also used in memory devices and power back-ups.

The supercapacitors are now used in many other application spaces where urgent power backup or immediate power bursts are required. The combination of supercapacitors with batteries can allow smaller and compact electrical power sources.

In the next tutorial, we will discuss inductors.

You may also like:

Filed Under: More Editor's Picks, Tutorials

Questions related to this article?

👉Ask and discuss on Electro-Tech-Online.com and EDAboard.com forums.

Tell Us What You Think!!

You must be logged in to post a comment.